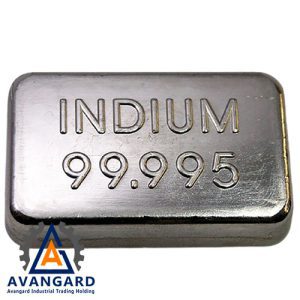

Tin Ingot

Product Code: 20029

Size: Ingot

Application: Alloying Element

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

Tin ingots are one of the metals used in various industries to meet needs and shortages. This metal is one of the oldest and most widely used metals discovered by humans. The use of tin metal in different alloys creates specific and unique features and capabilities. Bronze and also copper-tin alloy have sharpening capability and are highly durable, such that they can be used to make cutting edges. Cutting edges are made for use in hunting, weapons, and construction tools.

The geographical separation that occurred between tin consuming and producing nations has had a significant impact on the patterns of early trade routes. This metal has very diverse applications which can be briefly named as soldering in pipe connections, soldering electrical conductors, coating of steel containers, bearings, and other alloys for various practical uses.

Tin Ingot

By adding tin to copper, bronze alloy is obtained which has properties such as sharpness, cutting ability, and acceptable hardness. Other uses of tin metal include:

- As a coating on steel container lids

- Bearings

- Soldering electrical conductors

- Soldering pipe joints

- Making alloys of varying quality

Production of Tin Ingot

As you know, tin metal in its primary state can be produced in the form of molds, ingots, and rods. These productions are cast in weights of 50 kilograms or less and then offered to the market. If it is stated that the tin is grade one, it means commercially pure tin with a tin content of at least 99.8%. There are also higher grades known as electrolytic, where the minimum tin content reaches 99.95%, or it can even reach up to 99.98%.

To produce high-quality tin materials, advanced machinery is used. This usage of high-grade materials and advanced machinery ensures its high quality standards. In making high-quality alloys, superconductors, semiconductors, soldering, and many other items, this material is used. These ingots are used in various industries due to their lightness and high durability.

Types of Tin Ingot

Tin ingots are divided into two separate categories: the first category includes lead-bearing tin, and the second category includes lead-free tin.

These two categories of ingots have different alloys, and solder wire also benefits from these features. There is widespread use of these ingots, and it can be said that they have many and varied applications. For example, for soldering, instead of using a soldering iron and tin wire, the ingot is melted and the soldering operation is performed with a tin wave. This method is also used for soldering DIP components.

Lead-Bearing Tin Ingot and Its Features

The lead-bearing type is the best-selling type of ingot, identified by the 63.37% ingot. This percentage indicates the use of 37% lead and 63% tin. This type of ingot is suitable for use in tin baths due to its high resistance at high temperatures. These ingots are tested in reputable laboratories and offered as a reliable product. In the electronics industry, automatic devices, and others, these ingots are used due to their reasonable price and high quality. Other applications of this type include soldering electronic boards, which are also very suitable in this regard. The advantages of these ingots include reducing short circuits, reducing slag production, and reducing copper corrosion from the board.

Lead-Free Tin Ingot and Its Features

This type of tin ingot is also used for soldering, with the difference that soldering is done without nitrogen in this case. This type of ingot prevents copper corrosion, reducing the production of tin ash during the soldering operation. This soldering is done with a wave and is performed at temperatures of 260 to 270 degrees Celsius. The use of this lead-free tin ingot reduces tin oxidation, thereby reducing the need for maintenance and cleaning of the device, which in turn reduces costs.

Purchase Tin Ingot

Avangard company, with over 2 decades of experience in providing casting raw materials such as tin ingots with the best quality and reasonable price, is ready to offer services to you, esteemed customers.

Tin Ingot Price

For price inquiries and purchasing various types of tin ingots with the best quality and most economical price, contact the sales experts at Avangard Holding.

We apologize, prices are currently being updated. Please contact Avangard’s sales unit for price inquiries.

| Row |

Description |

Price in Toman |

| 1 | Price of Tin Ingot | Contact Us |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.