Screen Mesh

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

What is a Screen Mesh?

A screen mesh is one of the vital tools in various industries used for separating and sieving materials. Types of screen mesh include metal screen mesh, stainless steel screen mesh, and other meshes, each having its specific application depending on the needs. In the process of purchasing screen mesh, attention to the quality of the screen mesh and the mesh size is crucial, as these factors directly affect its performance and durability. The price of screen mesh varies depending on the material, size, and manufacturer. Industrial screen mesh is used in harsh and high-pressure environments, and for proper choice, studying the screen mesh purchase guide is essential. Avangard Holding, as a screen mesh manufacturer, can provide valuable advice on selecting the most suitable type of mesh. The application of screen mesh in various industries such as mining, agriculture, and construction, and its proper installation while following technical points, increase its lifespan and efficiency. Ultimately, the correct and timely selection of screen mesh according to specific industrial needs helps improve production quality and reduce costs.

Industrial Screen Mesh: How to Choose the Best Type?

Choosing the right screen mesh for a specific project requires considering several factors. First, the type of material to be sieved must be specified. For instance, if the material to be sieved is very heavy and abrasive, you will need a high-strength screen mesh. Additionally, attention must be paid to the mesh size and type of material. The choice of the appropriate mesh depends on the particle size and the sieving purpose. Finally, the type of working environment can also be influential; for example, humid environments require rust-resistant meshes.

Complete Guide to the Use and Maintenance of Screen Mesh

Proper use and maintenance of screen mesh increase its lifespan and efficiency. Initially, ensure the mesh is installed correctly with no deviation. Using damaged meshes not only reduces efficiency but may also damage machinery. After each usage period, meshes should be cleaned and any remaining particles should be removed. Moreover, if necessary, meshes should be replaced in a timely manner to prevent a decrease in product quality.

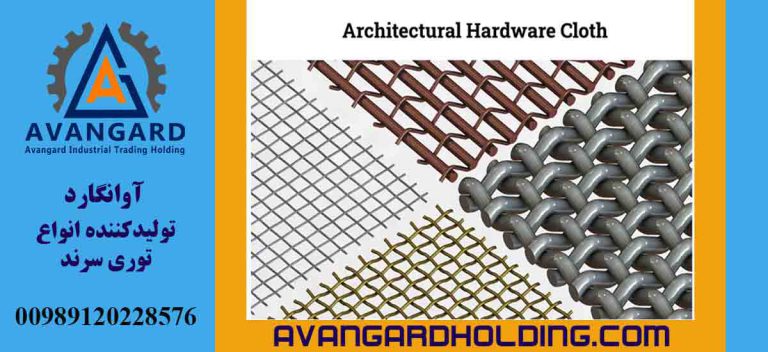

Types of Screen Mesh

Screen mesh is produced in various types, each suitable for specific applications. The main types of screen mesh include:

- Woven Screen Mesh: This type of mesh is made from steel or iron wires woven together, suitable for larger material separation.

- Knitted Screen Mesh: These meshes are made from metal or plastic and are used for sieving finer materials.

- Polyurethane Screen Mesh: These meshes are used in harsh environments due to their high resistance to abrasion and corrosion.

- Vibrating Screen Mesh: These meshes use mechanical vibrations to sieve and separate materials.

Materials of Screen Mesh

Screen mesh is made from various materials, each having its own advantages and disadvantages. Common materials include:

– Stainless Steel: These meshes are used in the food and pharmaceutical industries due to their high corrosion and rust resistance.

– Galvanized Iron: These meshes, coated with zinc, are resistant to rust and are used in humid environments.

– Plastic: Plastic meshes are lightweight and suitable for separating light materials and chemical environments.

– Polyurethane: Polyurethane meshes are used in tough and high-stress environments due to their high abrasion resistance and flexibility.

Technical Specifications of Screen Mesh in Table Format

| No. | Feature | Specification |

| 1 | Material | Stainless Steel, Galvanized Iron, Plastic, Polyurethane |

| 2 | Mesh Size | 0.5 mm to 100 mm |

| 3 | Wire Thickness | 0.1 mm to 10 mm |

| 4 | Mesh Dimensions | Custom (as required) |

| 5 | Abrasion Resistance | High (for Steel and Polyurethane) |

| 6 | Corrosion Resistance | High (for Stainless Steel and Galvanized Iron) |

| 7 | Weight | Variable depending on material and dimensions |

Advantages of Using Screen Mesh in Industry

Screen mesh, due to its wide applications and unique features, offers many advantages for various industries. Major advantages include:

- Increased Efficiency in Production Lines: Screen mesh allows precise and optimal material separation, preventing waste of time and energy.

- Cost Reduction: Using high-quality and durable meshes contributes to a longer lifespan and reduces the need for frequent replacements.

- Improved Product Quality: Precise material separation can enhance the final product quality, leading to the production of superior products.

- Flexibility in Application: Screen mesh can be used under various environmental conditions and with different materials.

Difference Between Metal and Plastic Screen Mesh: Which is Better?

Choosing between metal and plastic screen mesh depends on the specific project needs and environmental conditions. Metal meshes are more suitable for tough and heavy environments due to their higher resistance to impact and pressure. On the other hand, plastic meshes, due to their lighter weight and chemical resistance, perform better in lighter environments and with corrosive materials. Additionally, plastic meshes are usually less expensive and easier to install.

Knitted Screen Mesh: Advantages and Applications

Knitted screen mesh is one of the most widely used types of meshes in various industries. Due to its meshed structure, it allows precise separation of fine and coarse materials. Advantages of knitted screen mesh include high resistance to wear, high flexibility, and usability in various environments. These meshes are commonly used in industries such as mining, construction, and food, and due to the variety in mesh size and material, they can easily adapt to different needs.

Screen mesh is one of the key tools in many industries that helps improve production processes and increase product quality. Considering the wide variety in types and materials of screen mesh, correct selection and proper maintenance can directly impact the performance and costs of a project. By carefully reviewing the specific needs of the project and comparing the various features of the meshes, the best option can be selected and the unique benefits it offers to the industry can be leveraged.

Screen Mesh Size

The mesh size of a screen is a crucial factor in determining its performance and application in various industries. Choosing the right mesh size for a screen can directly affect the quality of separation and efficiency. Mesh refers to the number of holes per square inch of the mesh and is usually specified with a number like “Mesh 20” or “Mesh 100.”

Fine and Coarse Mesh Sizing

Meshes with fine mesh size (e.g., Mesh 100 or higher) are suitable for separating very small and fine particles. These types of meshes find more applications in industries such as food, pharmaceutical, and chemical, where precise separation is needed. For example, in sieving very fine powders, fine meshes are used to separate very small particles and enhance the quality of the final product.

Conversely, meshes with coarser mesh sizes (e.g., Mesh 20 or lower) are more suitable for separating larger particles. These types of meshes are used in industries like mining and construction, where high volumes of materials need separation. Coarse mesh allows materials to pass through faster, which can help increase the speed of the production process.

Iron Mesh Specifications

| Mesh Size | Wire Diameter | Dimensions | Weight | Dimensions | Weight |

| 4 mm | 2.6 mm | 100×150 cm | 22 kg | 100×200 cm | 28 kg |

| 5 mm | 3 mm | 100×150 cm | 22 kg | 100×200 cm | 28 kg |

| 6 mm | 3.2 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 7 mm | 3.5 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 8 mm | 3.8 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 9 mm | 4 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 10 mm | 4.2 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 12 mm | 4.5 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 14 mm | 4.7 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 15 mm | 5 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 16 mm | 5.2 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 18 mm | 5.5 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 20 mm | 5.6 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 22 mm | 6 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 25 mm | 6.3 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 28 mm | 6.5 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 30 mm | 6.5 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 32 mm | 6.7 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 35 mm | 7.2 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 40 mm | 7.5 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 50 mm | 8.5 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 60 mm | 9.2 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

| 70 mm | 9.2 mm | 100×150 cm | 22 kg | 100×200 cm | 30 kg |

Steel Mesh Specifications

| Mesh Size | Wire Diameter | Dimensions | Weight | Dimensions | Weight |

| 3 mm | 2 mm | 100×150 cm | 16 kg | 100×200 cm | 27 kg |

| 4 mm | 2.2 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 5 mm | 2.9 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 6 mm | 3.2 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 7 mm | 3.3 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 8 mm | 3.5 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 9 mm | 3.8 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 10 mm | 3.9 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 12 mm | 4.2 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 14 mm | 4.3 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 15 mm | 4.5 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 16 mm | 4.6 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 18 mm | 5 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 20 mm | 5.2 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 22 mm | 5.5 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 25 mm | 5.8 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 28 mm | 6 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 30 mm | 6.3 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 32 mm | 6.5 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 35 mm | 6.5 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 40 mm | 7 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 50 mm | 8 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 60 mm | 8 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

| 70 mm | 8 mm | 100×150 cm | 20 kg | 100×200 cm | 27 kg |

Effect of Mesh on the Price and Durability of Screen Mesh

The mesh size of screen mesh also affects its price and durability. Finer meshes are usually more expensive because their production process is more complex and requires higher precision. On the other hand, meshes with coarser mesh sizes are generally more economical but may have less resistance to pressure and abrasion.

Choosing the Right Mesh

Choosing the right mesh for screen meshing should be based on the type of materials to be sieved and the ultimate separation goal. For example, if the goal is to separate very fine particles, a finer mesh should be selected. However, if the speed of the process and the separation of larger particles are important, a coarser mesh would be more suitable. In general, the correct selection of mesh can significantly impact the efficiency, costs, and final product quality.

In conclusion, the mesh size of screen mesh is a key factor in its efficiency and should be chosen carefully according to the specific needs of each industry to achieve the best possible results. The table below provides an overview of mesh types and sizes in screen mesh along with the applications and related features of each type:

| Mesh | Hole Size (mm) | Features | Applications |

| Mesh 4-6 | 4.75 – 3.35 | Coarse mesh, rapid material passage, high resistance | Mining, large stone separation, construction industries |

| Mesh 8-12 | 2.36 – 1.68 | Suitable impact resistance, material passage | Mineral screening, sand and gravel separation, agricultural industries |

| Mesh 14-20 | 1.41 – 0.841 | Moderate accuracy in separation, suitable resistance | Mineral processing, chemical industries, largescale food screening |

| Mesh 30-40 | 0.595 – 0.42 | Higher accuracy in separation, suitable for fine materials | Food industries, powder separation, chemical screening |

| Mesh 50-70 | 0.297 – 0.210 | More precise separation, suitable for fine powders | Pharmaceutical industries, chemicals, paint processing, fine food separation |

| Mesh 80-100 | 0.177 – 0.149 | Very precise, suitable for extremely fine materials | Paint and resin production, cosmetics industries, pharmaceutical sieving |

| Mesh 150-200 | 0.104 – 0.074 | Very high precision, micron-sized material passage | Electronics industries, nanomaterial production, precise filtration |

Additional Descriptions:

- Hole Size (mm): This indicates the size of each mesh hole, measured in millimeters. The smaller this value, the finer the mesh.

- Features: Refers to the physical and functional characteristics of each mesh type, such as impact resistance, material passage speed, and separation accuracy.

- Applications: This column indicates the industries and processes where each mesh type is used.

This table helps you to select the appropriate mesh depending on the type and size of your needed materials.

Screen Mesh Pricing

Screen mesh price depends on several factors, including mesh material, mesh aperture size, wire thickness, weave type, and quality of raw materials. Screen meshes are used in mines for material separation and screening and are highly resistant to wear and corrosion due to direct contact with rough mineral materials.

Galvanized and stainless steel meshes, due to high resistance to corrosion and rust, generally have higher prices compared to iron meshes. Additionally, mesh aperture size also affects pricing; smaller meshes require more materials and thus cost more. Given the fluctuations in the iron and steel market, mesh prices consistently change, and it is usually recommended to contact suppliers for exact prices.

For an inquiry about the daily prices of various screen meshes for sand and gravel mines, it is recommended to provide desired specifications such as mesh size, material, and wire thickness to Avangard Holding’s sales experts to receive accurate and up-to-date pricing.

| No | Product Description | Price |

| 1 | Galvanized sand and gravel mine screen mesh price | Contact |

| 2 | Stainless steel sand and gravel mine screen mesh price | Contact |

| 3 | Iron sand and gravel mine screen mesh price | Contact |

| 4 | Abrasion-resistant steel screen mesh price | Contact |

| 5 | Screen mesh price with aperture 1 to 100 mm | Contact |

| 6 | Screen mesh price with sizes 2×1 and 1.5×1 meters | Contact |

| 7 | Screen mesh price suitable for coal mines and asphalt factories | Contact |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.