Rock and Rock Crusher Machine

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

Rock and Rock Sand Maker Crusher Machine (Rock and Rock)

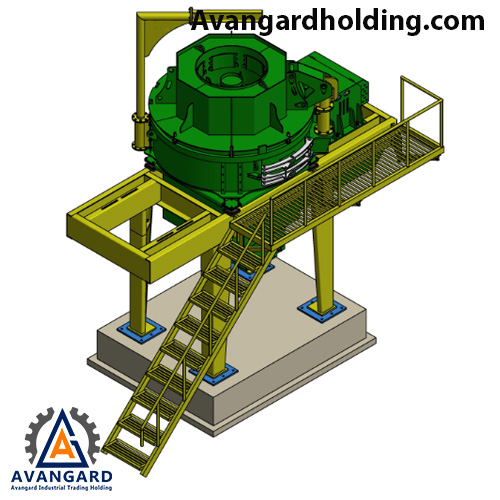

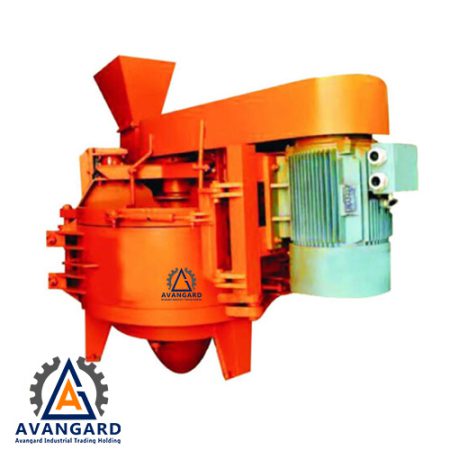

The Rock and Rock crusher machine (rak&rak) is used as a secondary or possibly tertiary crusher, classified as a Vertical Impact Crusher with an impact-based structure where the crushing process occurs around a vertical axis. To purchase or inquire about the price of the Rock and Rock crusher machine, contact the experts at Avangard Company.

The Rock & Rock crusher machine, known as a sand maker, is primarily used for sand production. The main difference between this crusher and other impact crushers is in its operation method, functioning like a centrifuge. Utilizing its high speed, materials are introduced into the device’s chamber, where they collide forcefully with the hammers mounted on the rotor, being thrown towards the body, continuing this cycle until they are finally crushed to the desired size.

This process not only reduces the internal spare part wear of the Rock and Rock compared to other similar machines but also increases the crush rate and the multifaceted nature of the produced materials (which significantly improves the output quality and productivity). Another advantage of this machine is the ease of changing parts.

Advantages of the Rock and Rock Crusher (Rock and Rock Sand Maker)

- High capacity

- Reduced energy costs

- Cubic-shaped product

- High product quality

- Reduced wear costs and low abrasion per ton

- Easy maintenance

The Rock and Rock crusher is efficient for producing high-quality composite products (producing sand for asphalt and concrete) and can fully crush various hard and soft ores (silica, feldspar, zinc, dolomite, barite, etc.).

The Rock and Rock crusher is a model of impact crushers. Impact crushers are available in vertical and horizontal types, with this being the vertical type. In this model of impact crushers, the rotor plays a crucial role in creating centrifugal force and consequently in the crushing process. In this model of crushers, the crushing process is performed by impact forces.

In these sand makers, the input materials and rock fragments are crushed by colliding with each other at high speeds, turning them into sand. The Rock and Rock crusher has a high production capacity, making this model unique and well-known in the industry. This device serves as a secondary crusher, suitable for crushing small rock fragments and not for larger stones.

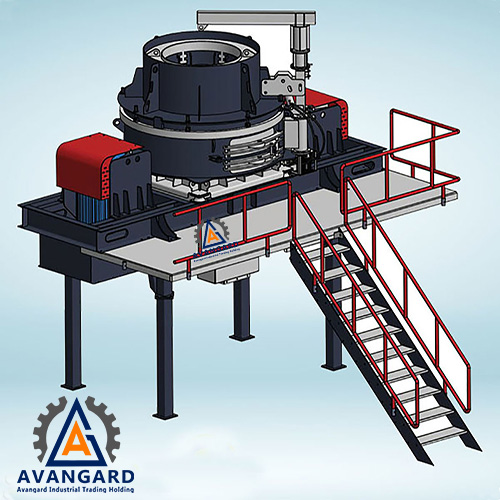

The Rock and Rock machine is one of the main and most used models for sand production mines and asphalt plants. It offers the best performance among similar crusher models. It should be noted that the Rock and Rock sand maker is available in three models: V8, V10, and V10H, available at Avangard Company, with details provided below.

| Technical Specifications of the Rock and Rock Crusher | ||||||

| Row | Model (cm) | Maximum Input Dimensions (mm) | Output Material Dimensions (mm) | Production Capacity(t/h) | Motor Power (kw) | Machine Weight (ton) |

| 1 | Rock & Rock Model V8 | 0-40 | 0-6 | 50-80 | 90 | 8325 Kg |

| 2 | Rock & Rock Model V10 | 0-45 | 0-6 | 60-120 | 132 | 9800 Kg |

| 3 | Rock & Rock Model V10H | 0-45 | 0-6 | 80-140 | 200 | 10 |

Rock and Rock Crusher (Centrifuge Rock and Rock)

The Rock and Rock crusher is used for crushing materials, aggregates, and fine particles with diameters ranging from 6 to 30 millimeters. This means this machine is suitable for crushing small stone pieces but is ineffective for larger stones and boulders. The output produced by this device will have a diameter ranging from 0 to 6 millimeters and can ideally produce between 26 to 30 tons per hour.

In the Rock and Rock crusher, hammers rotate around a vertical axis at high speeds and strike the input materials and stones multiple times, causing them to crush. This rotation generates centrifugal force. Due to this continuous rotation and the resultant forces, the material definition of each device part is critically important. All hammers of this crusher are made from tungsten carbide, whereas the rotor, which is the main and most effective part of the Rock and Rock device, is made from Hardox 400, which is abrasion-resistant.

The Rock and Rock crusher, also known as a fine crusher or sand maker, is used as a secondary crusher. The Rock and Rock device is capable of producing composite products in a multifaceted form. The production load in the Rock and Rock crusher is organized based on the latest standards for sand production for use in asphalt and concrete. The Rock and Rock crusher, also known as a centrifuge sand maker, is highly effective for crushing hard stones such as feldspar, silica, dolomite, barite, etc.

Product Generated by the Rock and Rock Crusher

One of the key aspects and prerequisites for producing a high-quality product is using high-quality raw materials and tools. Sand production is crucial due to its extensive application in various industries such as asphalt production or use in building materials for construction.

Generally, two methods are used to obtain sand. The first method uses riverbed stones that move with the river’s flow and, through continuous erosion, acquire a rounded and angled appearance. However, in the second method, the required sand is obtained by crushing ore stones. In this method, rock fragments are crushed in the Rock and Rock crusher to reach the dimensions expected by the customer.

The sands produced by the Rock and Rock crusher have sharp edges. These angular and multifaceted sands produced are very suitable for use in asphalt and concrete, which is why the primary application of products produced by the Rock and Rock device is for use in asphalt and concrete. These dimensions result from the stones being crushed with high intensity and speed. Another application of the Rock and Rock is to refine the particles of sand or sharpen their edges.

Operation of the Rock and Rock Crusher (Centrifuge Sand Maker)

The biggest difference between Rock and Rock crushers and secondary crushers compared to other crusher machines is that, in other devices, different hammers crush the sand, but in Rock and Rock crushers, this is not the case, and they are actually self-crushing. When materials and stone fragments are poured into the Rock and Rock crusher, it begins centrifugally spinning at high speed. Due to the high speed, stone particles and sand collide intensely, crushing each other.

For better operation, several hammers are installed inside the device to conduct more efficient and quicker sand crushing. One more advantage of the Rock and Rock crusher is its low wear and easy part replacement. This feature facilitates easier device usage, providing consumers with confidence that any problem or malfunction is readily addressable.

Unlike other devices, the Rock and Rock is equipped with special shock absorbers and vibration dampers, which reduce wear and tear and extend the device’s useful life.

Price of Rock and Rock Sand Maker Crusher Device

The price of the Rock and Rock sand maker crusher device varies depending on the type and capacity of the device, specific customer requests, and market price fluctuations. To order, buy, sell, or manufacture your desired device, contact our experts at Avangard Company.

We apologize, prices are currently being updated. Please contact Avangard Sales Department for price inquiries..

| Row | Description | Price in Toman |

| 1 | Price of Rock and Rock Sand Maker Crusher V8 | Contact |

| 2 | Price of Rock and Rock Sand Maker Crusher V10 | Contact |

| 3 | Price of Rock and Rock Sand Maker Crusher V10H | Contact |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.