Qubit Crusher Machine

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

What is a Qubit Crusher Machine?

The Qubit Crusher machine can be used as primary, secondary, and tertiary crushers. These crushers use impact force to mill mineral materials. The Qubit crusher is used for crushing quarry stones or river stones into sizes of 10 to 15 centimeters. The Qubit crusher machine is constructed from a rotor with 2 to 6 rows of hammer qobit, which rotates at high speed.

It serves as one of the primary and secondary crushers in mines such as sand and gravel, lime, and gypsum, and it crushes soft minerals of medium size, turning them into fine sand, chickpea, and almond-sized particles. The role of the hammer blades or hammer qobit is to throw the incoming load (stones and minerals) towards the inner wall of the crusher (qobit anvils or qobit side plates). With the rotor’s rotational movement, the incoming stones are hurled towards the walls and anvils for the crushing process to occur. Qubit hammers are used in impact crushers, and they line up inside the crusher for crushing.

Crushing Mechanism of the Qubit Crusher Machine

The Qubit crusher machine uses the high speed of the rotor to strike materials broken from previous stages. Incoming materials and stones are crushed upon impact with the hammer and are again struck by the hammers against the cover plate and finally discharged through the outlet. The user can adjust the gap between the rear frame and the rotor frame, allowing for changes in the size and shape of the material grains.

Performance Features of the Qubit Crusher Machine:

- A simple structure, unique performance, suitable for crushing hard stone.

- Low energy consumption, high performance, high crusher breaking ratio, generally 10-20, up to 50-60.

- With shaping functionality, the product is in cubic form, high packing density, adjustable discharge size, simple breakage process.

- Uniform grain distribution.

- Easy adjustment of feed quantity in the production line, allowing increased feed size.

- Utilizes impact-resistant gear made from new wear-resistant materials, often manganese steel.

- Easy use and maintenance.

The Qubit crusher machine is another type of impact crusher that crushes stone pieces using impact force. This horizontal impact crusher means its crushing action is based on rotor movement and speed. The Qubit crusher can be used as a primary, secondary, or tertiary crusher.

This machine is considered one of the most important and primary processing lines in most mines and processing factories. This machine typically has bodies that can be reassembled and dismantled. Additionally, this type of machine features facilities for part replacement, device upgrades, and output port bolt adjustments to control the size of the output materials.

Structure of the Qubit Crusher Machine

Qubit crushers consist of a rotor with two to six rows of hammer blades. The rotor is the most important and vital part of the crusher. This rotor rotates at very high speed. Qubit hammers project incoming load pieces like stones, salts, and minerals towards the anvils placed on the internal lining of the Qubit crusher. On the internal wall of the crusher, a number of alloy shields made from wear-resistant materials are installed. The function of these complementary shields is to act as barriers. Incoming load pieces are crushed and broken upon impact with these obstacles.

Capacity of the Qubit Crusher Machine

The final product size is directly influenced by the crusher’s capacity. The finer the final product, the more work the crusher must perform, reducing its capacity. Moreover, the gap between the anvils and rotor should be smaller so that the product is finer; when these plates are closer, the return load will be higher, limiting the device’s charging permission, thereby reducing production speed.

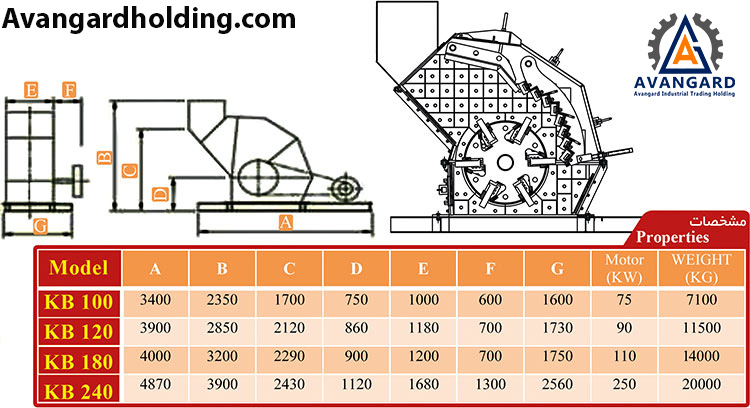

| Technical Specifications of Different Qubit Crushers | ||||||

| No. | Model | Maximum Input Dimensions (mm) | Output Material Dimensions (mm) | Production Capacity (t/h) | Motor Power (kw) | Weight (ton) |

| 1 | Qubit 80 | 50-80 | 0-20 | 60-80 | 50 | 6 |

| 2 | Qubit 100 | 50-100 | 0-25 | 80-100 | 50 | 7.5 |

| 3 | Qubit 120 | 50-150 | 0-30 | 100-120 | 70-75 | 11.5-12 |

| 4 | Qubit 180 | 50-200 | 0-35 | 150-180 | 90 | 14.5-15 |

Like any other mechanical device, Qubit parts require maintenance for increased productivity, and Avangard Company is ready to provide service to valued customers for supplying all Qubit parts as listed below:

- Qubit Hammer 180

- Qubit Hammer 120

- Qubit Rotor

- Qubit Anvil 120

- Qubit Rotor Cover

- Three Bolt Solid Qubit Anvil

- Qubit Ceiling

- Anvil Holder

- Two Bolt Solid Anvil

- Qubit Hammer Cartridge

- Qubit Crusher Shaft and Rotor

- Qubit Crusher Side Plates

- Qubit Hammer

- Qubit Hammer Cartridge

- Qubit Hammer Grip

- Two Bolt Ball Anvil for Qubit Crusher

- Three Bolt Ball Anvil for Qubit Crusher

- Slide Anvil for Qubit Crusher

- Hammer Cartridge for Qubit Crusher

- Anvil Spring for Qubit Crusher

- Bearing for Qubit Crusher

- Rotor Cover for Qubit Crusher

- Ceiling for Qubit Crusher

- Impact Absorber for Qubit Crusher

- Anvil Holder for Qubit Crusher

- Brow for Qubit Crusher

- Bolt and Nut for Qubit Crusher

- Adjustment Bolt for Qubit Crusher

- Bushing for Qubit Crusher

- Shaft Head Pulley for Qubit Crusher

- Electromotor Shaft Head Pulley for Qubit Crusher

- Shaft and Bearing for Qubit Crusher

Sales of Qubit Crusher

Sales of various Qubit crusher devices as primary and secondary crushers, various impact crushers in two types: simple and hydraulic, in single-sided and double-sided models (such as Qubit 80, Qubit 100, Qubit 120, Qubit 180, and Qubit 240) and types HS (HS7, HS10, HS11, HS14, HS16), ranging from 80, 100, 120, 180, 240 up to 300 tons per hour, manufactured with the best price by Avangard Company. To order the product at the most appropriate price, contact the experts in the impact crusher sales department.

Advantages of Using the Qubit Crusher Machine:

- High crushing power.

- Production of multiple fine materials for the production of asphalt and concrete.

- Easy maintenance.

- Ability to adjust hammers.

- Ability to adjust anvils.

- Easy access to spare parts.

Features of the Qubit Crusher Machine

The Qubit crusher has very high crushing power, and the produced product is shaped multifaceted, making it suitable for use in concrete and cement production industries. Another strong point of this machine is its easy repair and maintenance, with easy access to its spare parts. For easy inspection and repairs, multiple hatches are provided in this crusher. Additionally, these parts are available at reasonable prices.

The hammers and anvils in the Qubit crusher can be adjusted, with replaceable jaws between them. The hammers have a six-stage operational performance inside this machine and are easily replaceable. The operation of these hammers with six edges results in 75 to 85% consumption. The body of the Qubit crusher uses CK45 wear-resistant sheets as a lining. Similarly, rotor construction utilizes these parts and wear-resistant sheets.

To prevent dust from damaging components, bearings are placed in a protected state. Qubit crushers are the only type of impact crushers with a rotor guard. This guard protects the rotor, and with timely annual replacement and maintenance, the service life of the crusher increases. This device has unique features, some of which are mentioned here.

- Heavy rotor that reduces energy consumption and also reduces the amperage fluctuations of the Qubit crusher.

- High production speed and consequently high production capacity.

- High efficiency with uniform particle production.

- Application in all mining and cement lines, etc.

- Rotor with five blades of ST52 sheet with a thickness of 80 millimeters.

- High crushing ability compared to other crushers.

- Hammer retaining components on the rotor machined on all surfaces, enabling proper welding, which increases rotor service life.

- On-site repair capability.

- Adjustability of Qubit 120 anvils and Qubit 180 anvils.

- Easy access to replaceable parts of the Qubit crusher.

- Ability to adjust blade speed from 15 to 50 meters per second.

- The outer shell of the Qubit crusher machine is made of manganese steel or Hadfield with a thickness of 45 millimeters.

Qubit Crusher Prices

The price of Qubit crushers varies depending on the type and capacity of the device, such as Qubit 80, Qubit 100, Qubit 120, Qubit 180, and Qubit 240, or specific customer preference and price fluctuations. For ordering, buying, selling, and producing the desired device, contact our experts at Avangard Company.

| No. | Description | Price in Toman |

| 1 | Price of Qubit Impact Crusher Machine 100 | Contact Us |

| 2 | Price of Qubit Impact Crusher Machine 120 | Contact Us |

| 3 | Price of Qubit Impact Crusher Machine 180 | Contact Us |

| 4 | Price of Qubit Impact Crusher Machine 240 | Contact Us |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.