Jaw crusher machine

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

Jaw Crusher Machine and Its Functionality

Jaw crusher is one of the types of crusher machines used as a primary crusher. In this article, we will fully describe this machine and familiarize you with its functionality.

Introduction to Jaw Crushers (Jaw) (Jaw Plate)

Jaw crushers are considered one of the main crushing equipment in the mining and construction industries. These machines are very popular due to their simple structure, high efficiency, and lower costs compared to other crushing machines. Due to having an open mouth, which is the distance between the two jaws at the top, it has a very suitable performance for mountain and river stones.

The operation of this machine is such that in the first stage (primary crushing), large pieces resulting from blasting or extraction with natural dimensions are reduced in size to the extent that their dimensions are suitable for transportation by common means of transport (such as conveyor belts) and transfer to the next stage (secondary crushing) in a crushing system in grading workshops such as sand and gravel mines and stones like iron ore, clinker, quartzite, feldspar, dolomite, gypsum, lime, etc., which are very hard and abrasive, and other extraction factories are used.

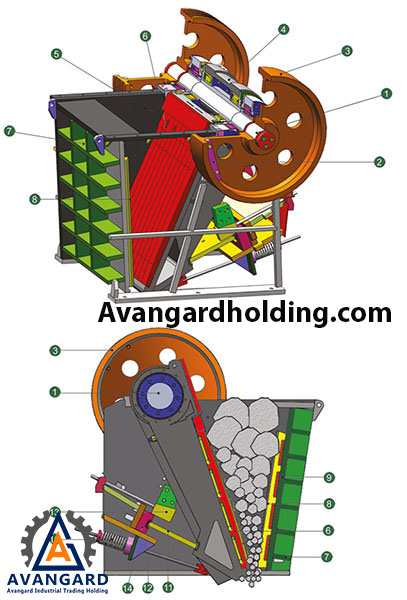

The jaw crusher is a device used for crushing large and hard stones and minerals. The mechanism of this device includes two fixed and movable jaws, where the materials entering between them are subjected to pressure and shear force and are crushed. The movable jaw, with its reciprocating motion, compresses the stones and creates smaller pieces from them. This type of crusher, sometimes called “toggle,” provides the necessary compressive force for crushing materials using vertical jaws.

This movable jaw moves with a cam mechanism and goes back and forth. The movement of the movable jaw plate is provided by an eccentric shaft connected to the motor by a belt and pulley. The movable jaw moves very slightly.

The necessary force for crushing the incoming stones is provided by a gear that causes the shaft to move, resulting in an eccentric force. This eccentric force causes the gap to close, and with the repetition of this operation, we witness the compression of materials, crushing them to the desired size, and finally exiting through the lower jaw of the crusher, called the discharge opening or throat.

The jaw plates in the jaw crusher play an important role and are made of resistant materials due to direct contact with hard materials. If you are looking to purchase or consult about different types of jaw crushers, contact the sales experts of Avangard Company to receive the best option suitable for your needs.

Common jaw crushers: 20*30- 30*50- 40*60- 45*65- 55*80- 30*90- 50*90- 60*90- 70*90- 30*125- 80*100- 90*110- 40*90- 63*100- 100*120, etc., which are named based on their rectangular input opening, for example, a crusher with dimensions 55*80 means a crusher with a length and width of the opening with these dimensions.

Jaw Crusher Sales

Avangard Company, with extensive experience in selling jaw crusher machines, offers various models of this machine to the market. The machines of this company are offered with high quality and reasonable prices. You can contact the sales consultants of Avangard Company to get more information about the purchase, sale, and production of various jaw crusher machines and their spare parts.

Mechanism and Functionality of the Device

It is one of the main types of crusher machines used and operated in mines under the name jaw crusher, and this type of crusher is excellently applicable in crushing minerals and stones larger than 20 cm.

In the jaw crusher machine, the dimensions of the jaw are determined based on the size of the input opening at the top of the device. The movable jaw is held back by a strong spring to ensure the safety of the device against very hard parts like metal pieces. The jaw crusher is made of manganese cast steel or Hadfield (DIN 1.3401) standard, which is resistant to wear and impact.

The Avangard technical team, with over two decades of experience in production and benefiting from a team of experienced engineers in mechanics, metallurgy, mining, and electricity, ensures that if needed, by changing the alloy composition and adding elements like manganese, molybdenum, titanium, and nickel, as well as modifying production methods and heat treatment, they solve the problems of miners and increase the resistance of the jaws against wear. These improvements lead to increased device efficiency and more effectiveness in harsh conditions.

The angle between the two fixed and movable jaws is about 27 degrees, and the crushing process takes place between the two jaws. In the jaw crusher, the input load dimensions are a maximum of 80 to 90 percent of the input opening. About 65 percent of the crushed product has dimensions smaller than the throat in the closed state, or 80 percent of it has dimensions smaller than the throat in the open state.

Two jaws; one fixed and the other movable exist in jaw crushers; the stones are placed between these two jaws and subjected to high pressure and impact, which, using shear, compressive, and impact forces, causes the stones to be crushed. It should be noted that these types of crushers are used for the initial stages of stone crushing.

Mechanical pressure is obtained by two jaws, one fixed and the other movable. These two jaw plates create a V-shaped cavity called the crushing chamber, where the top of the crushing chamber is larger than the bottom. The upper opening, due to having an open mouth, which is the distance between the two jaws at the top, has a very suitable performance for mountain and river stones, and the raw materials are mainly poured into the crusher hopper by an excavator or truck, and this part has the ability to remove small particles to be controlled in downstream machines, thus improving the device’s performance.

The narrower opening at the bottom of the crushing chamber is used for measuring discharged materials. A toggle plate and tension rods keep the Pitman close to the bottom of the movable jaw. The toggle plate is designed to act like a fuse and protect the crusher if an uncrushable material enters the crushing chamber. In summary, it can be explained that it consists of vertical jaws, where one of the jaws is kept fixed in the crusher assembly, called the fixed jaw, while the other jaw is called the movable jaw. This movable jaw moves with a cam mechanism and goes back and forth. The movement of the movable jaw plate is provided by an eccentric shaft connected to the motor by a belt and pulley. The movement of the movable jaw can be very slight, as the complete crushing process does not occur at one time.

Price List of Jaw Crusher Machine

Dear visitor: Due to currency fluctuations and prices, please contact the sales unit of Avangard Company for purchasing various jaw crusher machines at the most suitable price and checking availability.

Types of Jaw Crushers

In jaw crushers, materials including minerals and stones, etc., are subjected to pressure or shear forces between two plates (jaws), one of which is fixed and the other is movable, and are crushed and turned into smaller pieces. Each type of stone, depending on its type, characteristics, hardness, etc., reacts differently to crushing, and for this reason, a specific device must be used for crushing each model of stone. For this reason, the movement of the jaws is created in different ways, with the main goal being to create the maximum force in the space between the two jaws for crushing materials. Based on this, devices are divided into two categories of double-toggle and single-toggle based on the type of jaw.

-1Double Toggle Jaw Crusher:

This type of device has a larger feed opening compared to the single-toggle model to easily crush large stones and is also suitable for stones with very high hardness. This model has very high pressure and is used for crushing hard and very hard stones and generally has more power. The jaw movement in double-toggle devices is back and forth and oscillating.

In this type of jaw crusher, the movement of the eccentric movable jaw is transferred to the lower part of the jaw by a connecting rod and two toggles. This type of crusher is suitable for crushing minerals and stones including iron ore, granite, basalt clinker, quartzite, feldspar, dolomite, gypsum, lime, and ores that are very hard and abrasive.

2-Single Toggle Jaw Crusher:

These types of devices have a small feed opening and are used for stones that are relatively hard. The movement of the movable jaw in this device is simultaneously up and down and back and forth.

In the jaw crusher, the movable jaw is directly mounted on an eccentric shaft at the top and connected to a toggle at the bottom, resulting in an elliptical motion path. In this type of system, the jaws move down and up, back and forth, causing less pressure on both the jaws and the stones. This jaw crusher model has a smaller opening compared to the double-toggle model and is suitable for crushing and fragmenting hard stones.

Advantages of Using Jaw Crusher

Using a jaw crusher has several advantages. Firstly, this device is capable of crushing very hard and resistant stones that are difficult to crush by other methods. Secondly, high crushing speed and the production of high-quality materials are other advantages of this device. Additionally, the jaw crusher has low maintenance costs, and its parts are easily replaceable. Finally, its ease of use and cost-effectiveness have made it widely used in many industrial and mining projects.

Overall, jaw crushers, due to their appropriate and precise design and simple structure, have high capacities, low wear, and ease of maintenance, and are considered a basic and preliminary type of device in various sectors, including industries, and are often used to reduce the dimensions and size of various stones and minerals.

Many features and advantages can be named for the jaw crusher device. This crusher, due to the type of operation and movement of the jaws and the distance between them, has a high capacity for production. Due to the shape and geometry of the crushing chamber, this chamber has little wear during crushing, and for this reason, it will have a longer life compared to other crushers. Also, the jaw crusher has easy maintenance conditions and, due to its special design and integrated drive motor, has a simple installation.

Some of the most important advantages of the jaw crusher are:

- Beautiful design and reliable performance

- High power and capacity in crushing stones

- Due to high capacity, the first priority in production lines

- Adjustable discharge opening to the desired size

- Lower price compared to other crushers

- Easy and cost-effective service and maintenance

- Quick and easy replacement of spare parts

- More resistance and less wear compared to other crushers

- High efficiency and reduced maintenance costs with a lubrication system

- Uniform output load

- The least wear among crusher types

- Low wear of spare parts

- High speed

- High capacity

Features of Using Jaw Crusher

- Easy and cost-effective repair and maintenance

- Strong structure and high resistance

- Stable performance

- High strength and power

- Low wear

- Very simple lubrication system

- Low spare parts costs

- Wear parts made of manganese steel – Ni Hard – HiCr

- Less wear and higher resistance compared to similar crushers

- Very suitable and uniform production rate

Material of Main Components of Jaw Crusher

Jaw crushers are heavy machines and are therefore made very resistant. The body and outer frame of this crusher are usually made of cast iron or steel.

- The internal body of the device is equipped with replaceable liners made of manganese steel, with manganese as the main element at about 13%, or Ni-hard alloy cast iron or high-chrome ASTM A532.87 (Hi-Cr) cast iron, to ensure minimum corrosion of the device components by defining the right alloy for the liners.

- Also, the jaw plates are made of manganese cast steel or Hadfield steel with DIN standard number 1.3401, which are wear-resistant and impact-resistant. The Avangard technical team, relying on over two decades of production experience and the high scientific level of mechanical, metallurgy, mining, and electrical engineers, all graduates from top domestic and international universities, assures miners and industrialists that if needed, by making changes in the alloy and adding elements such as manganese, molybdenum, titanium, nickel, and other useful elements, and changing the production method and heat treatment cycle, they can solve potential problems for miners, ensuring greater resistance to wear, which increases efficiency and improves performance.

- The main shaft of jaw crushers is made of MO40 steel with DIN standard number 1.7231.

- The bearings are made of carbon steel GS-45 with DIN standard number 1.0443, and the body bearings are machined integrally by a boring machine, which improves the lifespan and performance of the roller bearings.

- The toggles used are made of carbon steel GS-45 with DIN standard number 1.0443, with exceptionally high performance.

Components of Jaw Crushers

The jaw device consists of the following components:

- Product grading adjustment section

- Power generator device

- Jaws (spring and tension rod)

- Body

- Power transmission section

Spare Parts of Jaw Crusher

Spare parts

- Fixed jaw plate

- Movable jaw plate

- Jaw holder

- Side plate

- Jaw bearing

- Jaw back

- Short channel

- Long jaw channel

- Jaw toggle

- Toggle adjuster

- Flywheel

- Bearing

- Covers and parts

- Jaw eccentric shaft

- Electric motor

Price List of Jaw Crusher Spare Parts

Dear visitor: Due to currency fluctuations and prices, please contact the sales unit of Avangard Company for ordering, purchasing, selling, and producing various jaw crusher devices at the most suitable price and highest quality, and checking availability. It should be noted that all parts are presented to esteemed customers with a valid warranty from Avangard.

| No. | Parts List | Price in Toman |

| 1 | Price of fixed jaw plate for jaw crusher | Please contact us |

| 2 | Price of movable jaw plate for jaw crusher | Please contact us |

| 3 | Price of jaw holder for jaw crusher | Please contact us |

| 4 | Price of jaw bearing for jaw crusher | Please contact us |

| 5 | Price of jaw toggle for jaw crusher | Please contact us |

| 6 | Price of jaw back for jaw crusher | Please contact us |

| 7 | Price of short channel for jaw crusher | Please contact us |

| 8 | Price of long jaw channel for jaw crusher | Please contact us |

| 9 | Price of jaw eccentric shaft | Please contact us |

| 10 | Price of electric motor | Please contact us |

| 11 | Price of bearing | Please contact us |

| 12 | Price of side plate for jaw crusher | Please contact us |

| 13 | Price of covers and parts | Please contact us |

Specifications of Jaw Crusher Devices:

| No. | Model (Cm) | Max Input Dimensions (mm) | Output Material Dimensions (mm) | Production Capacity (t/h) | Motor Power (Kw) | Device Weight (ton) | Dimensions (Length*Width*Height) (mm) |

| 1 | 30*20 | 180 | 20-80 | 15-20 | 30 | 2 | 1010*1070*1100 |

| 2 | 50*30 | 280 | 30-90 | 30-50 | 37 | 4.5 | 1040*1250*1070 |

| 3 | 60*40 | 380 | 40-100 | 40-60 | 45 | 6.5 | 1390*1520*1550 |

| 4 | 65*45 | 430 | 40-100 | 40-60 | 45 | 7 | 1570*1540*1710 |

| 5 | 55*80 | 520 | 50-120 | 80-120 | 55 | 11 | 1800*1850*1950 |

| 6 | 90*30 | 280 | 30-100 | 60-80 | 55 | 7.5 | 1650*2070*1640 |

| 7 | 90*50 | 480 | 50-120 | 90-130 | 75 | 12 | 1900*2200*1930 |

| 8 | 90*60 | 580 | 90-180 | 150-200 | 90 | 16 | 2520*2300*2410 |

| 9 | 90*70 | 680 | 70-150 | 150-200 | 90 | 18 | 2440*2280*2400 |

| 10 | 30*125 | 280 | 20-100 | 80-100 | 55 | 10 | 1750*2325*1800 |

| 11 | 80*100 | 780 | 90-180 | 150-200 | 90 | 16 | 2100*2280*2360 |

| 12 | 90*110 | 880 | 90-200 | 250-300 | 90-110 | 24 | 2250*2550*2950 |

| 13 | 90*40 | 380 | 40-100 | 70-130 | 55 | 11 | 1112*2190*1700 |

| 14 | 63*100 | 600 | 63-200 | 75-160 | 75 | 16 | 1610*2300*2100 |

| 15 | 100*120 | 950 | 150-300 | 275-500 | 120-140 | 43 | 2585*2725*2715 |

| 16 | 110*120 | 1050 | 125*275 | 300*600 | 150-200 | 45 | 2600*2500*3000 |

| 17 | 107*140 | 1000 | 200-350 | 500-600 | 200 | 52 | 440*3000*3800 |

| 18 | 130*150 | 1250 | 200-400 | 400-1000 | 200 | 70 | 3050*2900*4500 |

| 19 | 30*150 | 250 | 35-100 | 80-100 | 75 | 12 | |

| 20 | 40*160 | 350 | 40-100 | 100-130 | 75 | 16 |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.