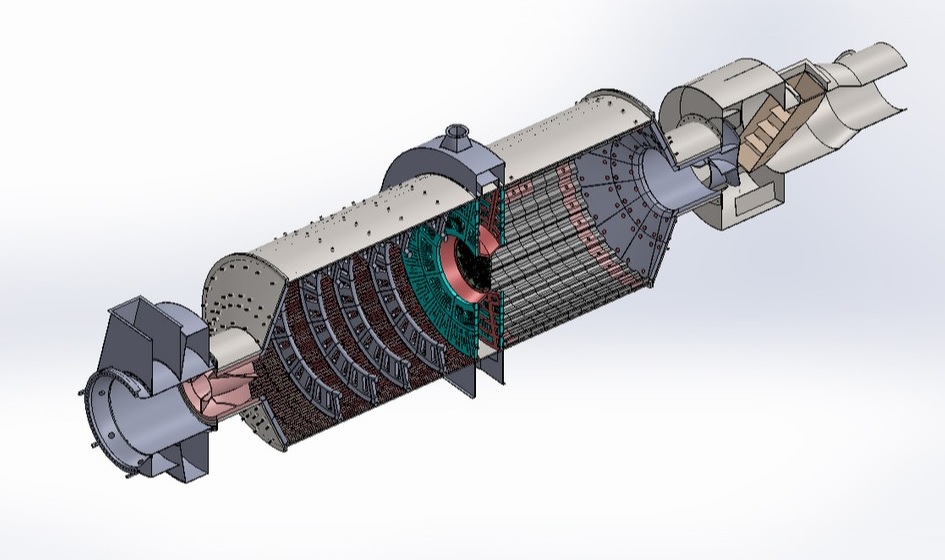

Grooved Ball Mill

Product Features:

Part Code: 10200

- Material:

- Manganese Steel Din 1.3401

- Manganese Molybdenum Steel Din 1.3401

- Unit Weight: 31.5 Kg

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$95 - $103

Dear user, prices are being updated, please contact us.

The Ball Mill is another component of Sand Maker Parts, featuring a thick-walled drum covered internally with replaceable wear-resistant liners made from manganese steel or manganese molybdenum steel, constantly rotating. Inside, it contains forged steel balls or ceramic balls that rise on one side of the drum and then cascade down onto the materials like a waterfall. This action crushes and grinds the particles placed between the balls and the liner, which can be either grooved or plain, through impact, abrasion, and pressure.

Production of Grooved Ball Mill

Its pulverizing mechanism is based on the rotational movement of the cylinder, creating friction between the balls and materials. The ball mill is a horizontal cylinder that rotates at a relatively slow speed. The movement of the device is created by a large external gear, which is connected through a smaller gear to the gearbox and electric motor of the machine.

Inside the cylinder, there are steel balls and wear-resistant liners made of manganese steel or manganese molybdenum steel, which are easily replaceable. This type of mill can be used in dry and wet processes, with different outlet mechanisms for each type.

Types of Ball Mills

Ball mills are divided into two types based on the method of input and output: continuous and batch ball mills.

1- Continuous Ball Mill

2- Batch Ball Mill

What is a Continuous Ball Mill?

In continuous ball mills, raw materials are continuously fed from one side of the mill and exit from the other side after grinding. This feature eliminates the need to stop the mill for loading and unloading. Even in conical ball mills, there is no need to stop the mill to charge the balls as they are injected along with the raw materials.

What is a Batch Ball Mill?

In batch ball mills, the raw materials along with the balls are fed into the mill at once, up to the mill’s capacity, and ground for a specified time. Then the mill is stopped and the ground materials are discharged.

Purchase Grooved Ball Mill

The grooved ball mill, made from manganese steel with Din 1.3401 standard and manganese molybdenum steel with a unit weight of 32 kilograms, is produced with the highest quality and best price at the foundry. Please contact Avangard’s sales experts for pricing inquiries, orders, receiving technical specifications, and catalogs for grooved ball mill parts.

Price List for Grooved Ball Mill

We apologize, prices are currently being updated. Please contact Avangard’s sales unit for price inquiries.

| Row | Description | Price in Toman |

| 1 | Price for Grooved Ball Mill | Contact Us |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.