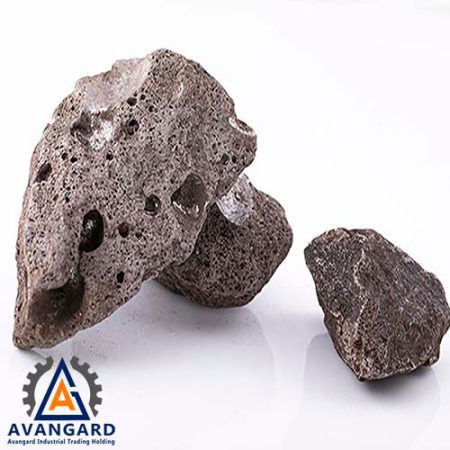

Ferrosilicon

Product Code: 20011

Size:

1- 0-3mm

2- 3-10mm

3- 10-60mm

Application: Alloy element – Nucleating agent – Degasifying agent

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

Ferrosilicon is one of the most used ferroalloys in the industry. This alloy is a combination of iron and silicon, produced by heating, melting, and reducing iron oxide and silica (quartz) using carbon materials such as coal, metallurgical coke, and charcoal in electric arc furnaces. The compositional ratio of this ferroalloy generally includes 10-90 percent silicon and the rest iron. Also, impurity elements such as aluminum, calcium, manganese, and others are present.

Ferrosilicon is obtained by reducing silicon from silica stone or silica sand in a melt. This ferroalloy has high amounts of silicon (more than 50 percent) produced in electric arc furnaces and with lower amounts (less than 20 percent) in blast furnaces. Typically, the silicon percentage in ferrosilicon is about 75 percent, and these grades contain 2 percent aluminum and calcium impurities.

Ferrosilicon is used as a source of silicon in the melt and to reduce metals from their oxides. It is also used to prevent oxidation in steel and steel alloys. Ferrosilicon is additionally used to prevent corrosion and increase resistance at high temperatures, increasing the carbide formation rate in cast iron.

Ferrosilicon

Ferrosilicon is one of the most important ferroalloys in metallurgy and steelmaking industry, produced as a combination of iron and silicon. This alloy is obtained through heating, reducing, and melting iron and silica stones (quartz) by carbon, often in electric arc furnaces. The compositional ratio of this ferroalloy mainly consists of 10 to 90 percent silicon and the rest iron. Other impurity elements such as manganese, chromium, phosphorus, sulfur, and aluminum may be present in amounts less than 0.5 percent in ferrosilicon. Carbon is also present as an impurity and as the third element in some types of ferrosilicon.

Applications of Ferrosilicon

1. Deoxidizing ferrosilicon in steelmaking:

Ferrosilicon has a higher oxidation capability than many main metals in the metallurgical industries and is used as a deoxidizing agent in many industrial alloys. This application is mainly used in steelmaking and steel casting industries.

2. Ferrosilicon as an alloying element in steel and cast iron production:

Silicon is one of the important alloying elements in the family of iron alloys and is used as an alloying element in the production of cast irons and steels. Cast irons usually contain various amounts of silicon, which is added to them via ferrosilicon.

3. Ferrosilicon as a nucleating agent in gray cast iron casting:

Using ferrosilicon as a nucleating agent in the production of gray cast iron, which is usually composed of lime, iron, and carbon, is common.

4. Ferrosilicon as a reducing agent in the production of other ferroalloys:

Ferrosilicon is used as a reducing agent in the production of some ferroalloys like ferro molybdenum, ferro vanadium, and magnesium production.

| Granulation (millimeter) | ||

| Ferrosilicon 60-10 | Ferrosilicon 10-3 | Ferrosilicon 3-0 |

| Material | Chemical analysis and percentage | |||||||||

| Si | Al | P

max |

S

max |

C

max |

Mn

max |

Cr

max |

Ti

max |

|||

| More than | Up to | More than | Up to | |||||||

| FeSi75Al1 | 72.0 | 80.0 | – | 1.0 | 0.05 | 0.04 | 0.15 | 0.5 | 0.3 | 0.2 |

| FeSi75Al1.5 | 72.0 | 80.0 | 1.0 | 1.5 | 0.05 | 0.04 | 0.15 | 0.5 | 0.3 | 0.2 |

| FeSi75Al12 | 72.0 | 80.0 | 1.5 | 2.0 | 0.05 | 0.04 | 0.20 | 0.5 | 0.3 | 0.3 |

| FeSi75Al13 | 72.0 | 80.0 | 2.0 | 3.0 | 0.05 | 0.04 | 0.20 | 0.5 | 0.5 | 0.3 |

| Type | Si% | Al% Max | Granulation (mm) |

| F1 | 72-78 | 2 | 10-60 |

| F2 | 72-78 | 2 | 60-120 |

| F3 | 74-78 | 2 | 10-60 |

| F4 | 72-78 | 2 | 10-60 |

| F5 | 72-78 | 2 | 10-60 |

| F6 | 72-78 | 1.5 | 10-60 |

| F7 | 72-78 | 2 | 10-60 |

| Size | C | S | P | Al | Si | Ferro silicon |

| 10-60

3-10 0-3 |

0.2% | 0.04% | 0.05% | 1.5% | Min 75-80% | |

| Size | C | S | P | Al | Si | Nucleating agent

Under Siconoc |

| 0.2-0.6

2-6 |

0.2% | 2-2.05% | 0.05% | 1-1.5% | Min 75-80% |

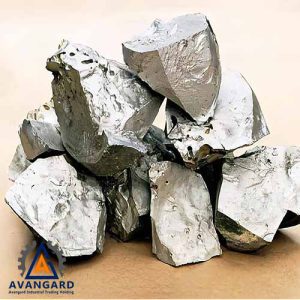

Production of Ferrosilicon

The production of ferrosilicon requires special equipment and facilities that need to be professionally and precisely designed and operated. Various equipment are used in ferrosilicon factories, including:

1. Electric arc furnaces: These furnaces are used for heating, reducing, and melting raw materials. They must be appropriately designed to provide suitable conditions for the ferrosilicon production process.

2. Material handling and transfer machinery: Special machinery is used in ferrosilicon factories to carefully and precisely transport and move raw materials.

3. Raw material crushing equipment: Raw materials may need to be crushed to be prepared adequately for the ferrosilicon process.

4. Cooling and freezing equipment: Cooling and freezing equipment is required to manage the heat generated during the melting and ferrosilicon production process.

5. Equipment for granulation and cooling: Various equipment is needed for processing and managing materials after production, including granulation and cooling.

6. Skilled workforce: The production of ferrosilicon requires skilled and expert workers who can manage and execute the production process.

Overall, successful ferrosilicon production requires not only raw materials but also appropriate equipment and skilled and experienced workforce to deliver the best quality and efficiency.

![]()

Undoubtedly, the ferrosilicon production process is accompanied by the production of a large amount of gas and dust, which requires proper management and control. To protect the well-being of the residents and protect the environment, the installation of dust removal systems is essential. In this process, raw materials, including silica stone (quartz), which are granulated and have an oxidized shell, along with reducing agents like coal, coke, and charcoal, are introduced into the smelting furnace through material transfer systems. This charge is reduced and melted in an electrometallurgical process by electrodes at a current intensity of about 120 kiloamperes and at a temperature of about 2500 degrees Celsius.

Purchase of Ferrosilicon

Avangard Company, with over 2 decades of experience in sourcing raw casting materials such as ferrosilicon with the best quality and reasonable prices, is ready to provide services to you, dear customers.

Ferrosilicon Price

For price inquiries and purchasing various types of ferrosilicon with the best quality and the most economical prices, contact the sales experts at Avangard Holding.

We apologize, prices are currently being updated. Please contact Avangard’s sales unit for purchase price inquiries.

| Row |

Description |

Price in Toman |

| 1 | Price of Ferrosilicon Size 3-0 | Contact Us |

| 2 | Price of Ferrosilicon Size 10-3 | Contact Us |

| 3 | Price of Ferrosilicon Size 60-10 | Contact Us |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.