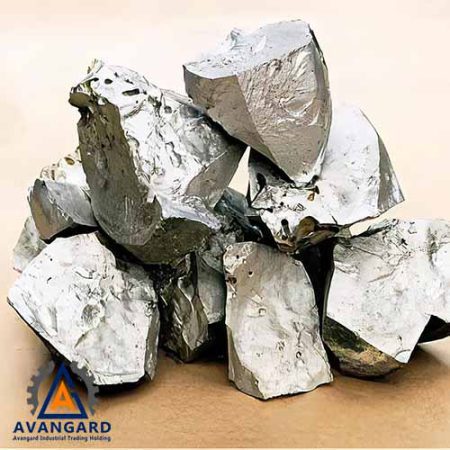

Ferro Molybdenum

Product Code: 20018

Size: Lumps

Application: Alloying Element

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

Ferro Molybdenum is a ferroalloy produced from the combination of iron and molybdenum. This ferroalloy is extensively used in the production of various steel alloys, particularly high-strength low-alloy steels and stainless steels. It is also used in cast irons, high-speed steels, tool steels, and superalloys. These ferroalloys are categorized based on the amount of molybdenum present in them, with the purity range of 60 to 70 percent molybdenum being the most commonly used in the industry. The density of Ferro Molybdenum is 9 grams per cubic centimeter and its melting temperature is 1680 degrees Celsius.

The majority of the use of this ferroalloy is seen in the manufacture of alloy steels. It is used in the production of machine parts, drill bits, military industries, stainless steel, and high-temperature-resistant steels used in chemical environments, components utilized in the petrochemical industry, as well as in turbines and generators. Molybdenum is recognized as a refractory metal with a high melting point, hence it can be expected that Ferro Molybdenum is employed to produce components required at elevated temperatures. This has led to its extensive usage in superalloys that operate at high temperatures.

Ferro Molybdenum Specifications

| C | S | P | Si | Fe | Mo | Element |

| Max 0.5 % | Max 0.1 % | Max 0.1 % | Max 1.5% | 22-33 % | 75–65 % | Percentage of Elements |

Production of Ferro Molybdenum

To produce Ferro Molybdenum, molybdenum ore, which visibly exists as the oxide ore (MoO3), is extracted from mines and combined in Ferro Molybdenum production lines with aluminum powder, iron powder, and a slag-forming flux. With the transfer of initial activation energy, an exothermic aluminothermic reaction occurs (it should be noted that this reaction is accompanied by a release of a substantial amount of energy). After completing the above process, the produced Ferro Molybdenum is subjected to a melting reaction (primarily through electron beam melting) and purified.

Applications of Ferro Molybdenum

Adding Ferro Molybdenum to steel and tools creates significant effects, which are outlined below:

- Increases steel’s strength and weldability

- Improves steel’s resistance to wear, temperature, and high heat

- Grants steel a secondary hardening point

- Resists hydrogen cracking

- Provides energy needed for dissolving new atoms

Purchase of Ferro Molybdenum

Avangard Company, with over 2 decades of experience in sourcing raw casting materials such as Ferro Molybdenum with the best quality and competitive price, is ready to provide services to our esteemed customers.

Ferro Molybdenum Price

For price inquiries and to purchase various types of Ferro Molybdenum with the highest quality and most economical prices, contact the sales experts at Avangard Holding.

We apologize, prices are being updated. Please contact Avangard’s sales unit for price inquiries.

| No |

Description |

Price in Toman |

| 1 | Ferro Molybdenum Price | Contact us |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.