Conveyor Roller

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

What is a Conveyor Roller?

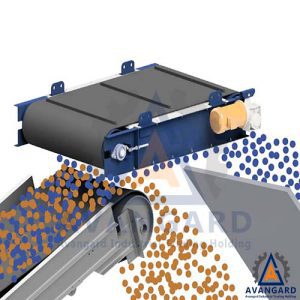

A conveyor roller or conveyor idler is one of the vital components in conveyor systems that plays an important role in the movement of products and objects. These industrial parts, designed as rotating circles, continuously move on axes allowing the transfer of objects from one point to another. The presence of rollers in conveyors has greatly contributed to enhancing production speed and improving factory performance. Additionally, using these parts can reduce additional costs and improve system efficiency.

Rollers are produced in different types in terms of material, dimensions, and application. The most important point in choosing and buying a conveyor roller is considering the build quality, material, diameter, and thickness. Conveyor roller standards, conveyor roller prices, and also conveyor drum prices are among factors that should be considered. The number of rollers needed in a conveyor depends on its length and typically, longer conveyors require more rollers.

Roller conveyors, which incorporate a series of rollers, are used in various industries including factories, warehouses, and production facilities. These conveyors allow for the manual, gravity, or electromotor-assisted movement of goods and play a significant role in various production processes.

Importance of Choosing the Right Roller

Choosing the right roller for a conveyor depends on several factors including the type of material being conveyed, the required load-bearing capacity, environmental conditions, and the speed of belt movement. Therefore, familiarity with conveyor roller standards and roller prices is of particular importance.

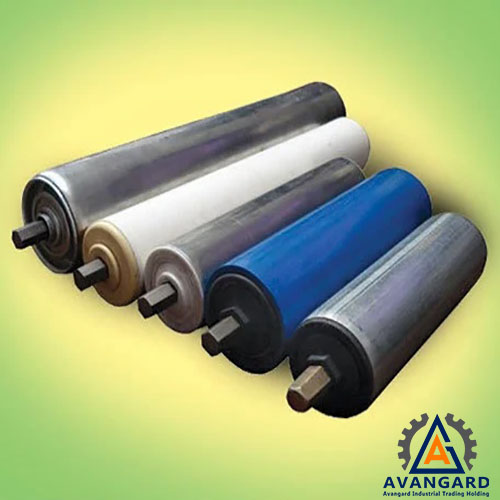

Types of Conveyor Rollers

Conveyor rollers are produced in various types including steel, cast iron, polyethylene, and rubber rollers. Each of these roller types has its own specific features and applications and is suitable for different working conditions. The appropriate roller choice depends on the specific industrial needs and application type.

In the market, conveyor rollers are offered in various designs and sizes based on application range and design method. Each company or factory requires a roller with specific weight, conditions, and control based on its application range. Rollers are generally categorized based on body material, diameter, thickness, and application type, all of which impact their performance and durability.

Different types of conveyor rollers include polymeric rollers, return rollers, press-fitted and standard rollers, replaceable rollers, and metal rollers. Each type has its own advantages and disadvantages and is used based on industrial needs. When selecting the appropriate roller, besides the mentioned features, attention to roller prices and related standards is also important to ensure optimal performance and longer equipment lifespan.

Polymeric Roller

Polymeric rollers are another type of conveyor roller that are increasingly used in specific industries today. Because they are made of polymer, these rollers do not cause wear when in contact with softer materials than metal. They are especially popular and common in ceramic manufacturing, tile industries, cement, and petrochemical industries. Among the main advantages of these rollers are electricity consumption reduction in industries and their high resistance to wet and humid conditions, making them an ideal option for such areas.

Return Roller

Return rollers are among the most used types of conveyor rollers in the market. The forward roller is used to bear the weight of the conveyor belt and has a side surface that evenly distributes the weight on the belt. In contrast, the return roller is also used to support the weight of the conveyor belt but is located on the lower surfaces of the conveyor. The main difference between these two models is their placement and the amount of weight each has to support.

Press-Fitted and Standard Rollers

Press-fitted and standard conveyor rollers are another common categorization. Standard rollers, which are cheaper, are typically supplied with simpler bearings and are suitable for light applications. By contrast, press-fitted rollers use newer and higher quality bearings, thus offering higher work capacity, technical durability, and longer lifespan.

Due to their high weight-bearing capacity, press-fitted rollers are one of the most popular choices in industries and mines. These rollers are manufactured in various sizes, including 60, 76, and 90 mm, and are widely used in heavy-load transport systems.

Press-fitted rollers, due to their high weight tolerance and resistance to various conditions, have become one of the most utilized types of rollers. They are typically produced in different sizes, including 60, 76, and 90 mm, and are used as a primary option in industries and mines.

Replaceable Roller

Replaceable rollers are custom-made, allowing for bearings to be replaced. Customers can choose to use new bearings or second-hand ones. Another important feature of these rollers is the provision of a surface to prevent dust from entering the bearings, helping to maintain optimal performance and extend the roller’s lifespan.

Metal Roller

Metal rollers, being one of the main components in conveyor systems, play an important role in the transportation of materials. These rollers are typically made from high-strength metal pipes and are manufactured and welded in factories.

Advantages of Metal Rollers:

- High resistance: Metal rollers have good resistance to wear and corrosion due to their metal composition.

- Durability and long lifespan: These rollers have a long useful life due to their strong and durable structure.

- Diversity of application: Metal rollers are used in various industries, including food, pharmaceutical, and manufacturing industries.

Limitations of Metal Rollers:

- Heavier than some other rollers: Due to the metal material, metal rollers usually weigh more than plastic rollers.

- Potential for rust in moist environments: If not properly coated, these rollers may be exposed to rust.

Comparison of Metal Roller with Steel Roller:

Compared to steel rollers, metal rollers are generally more economical, but steel rollers offer much higher resistance to corrosion and rusting, making them more suitable for corrosive environments.

Choosing the Right Metal Roller:

For selecting the appropriate metal roller, factors such as the type of material being conveyed, required load capacity, environmental conditions, and budget should be considered. Moreover, proper coating of rollers can enhance their useful life and prevent corrosion-related issues.

Types of Roller Based on Body Material

Conveyor roller types are also categorized based on body material and construction material. Steel and metal bases are usually used for roller construction, which can significantly influence the price. Some metals, due to their higher resistance to oxidation and corrosion, are better options for long-term use and provide greater durability. Choosing the appropriate material based on environmental conditions and your specific needs can help improve roller performance and extend its useful life.

Aluminum Roller

Aluminum conveyor rollers are among the best and most durable options in the market, although they have a higher price compared to other types of rollers. An important feature of these rollers is that they are rust-resistant and do not discolor over time. The choice of body material and the type of construction material for conveyor rollers is a specialized subject, and for an optimal choice, consultation with Avangard sales experts is necessary.

Steel Roller

Steel rollers are made from stainless materials in types 304 and 316 and are offered in press-fitted and replacement models. The outstanding feature of these rollers is their high resistance to corrosion, oxidation, and rusting. Moreover, these rollers also perform very well in terms of weight resistance and are offered at a reasonable price, making them an economical and efficient choice for use in conveyors.

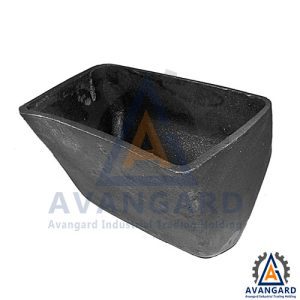

Cast Iron Roller

Cast iron rollers are a very suitable choice in terms of technical durability. Due to their high resistance to corrosion, heat, and impact, cast iron has a long lifespan. These rollers are typically designed in a conical model, and due to their unique features, their price is usually lower than other metals. These features make cast iron rollers an economical and effective option for use in conveyors and material transfer systems in various industrial conditions.

Teflon Polymer Roller

Teflon and polymer rollers are especially suitable for use in tile and ceramic factories and food industries. These materials, due to their non-lead structure and superior sanitary features, are considered excellent choices. Polymeric conveyor rollers, due to their low resistance to microbial growth, provide more sanitary conditions and are therefore particularly recommended in the food industry. These features make Teflon and polymer rollers an excellent option for maintaining health and hygiene in food production and transfer processes.

Guide Roller

Guide rollers are responsible for directing and regulating the path of conveyor belts. These rollers are usually less expensive than other conveyor models, but their application is more limited and primarily used for precise path control of conveyor belts in specific sections of transport systems. Guide rollers help maintain conveyor belt alignment and prevent deviations and disruptions in belt performance.

Conveyor Roller Manufacturing

The process of manufacturing a conveyor roller, or conveyor idler, involves various stages including design, cutting, welding, and coating. Using quality raw materials and adhering to production standards will ensure the rollers have a long lifespan and optimal performance.

Conveyor Roller Base and Roller Weight

The conveyor roller base plays an important role in supporting the roller’s weight and establishing the structural strength of the system. The weight of the conveyor roller also depends on its material and dimensions, affecting the system’s load-bearing capacity.

Buying Conveyor Rollers

If you intend to buy conveyor rollers, or in other words, buy a conveyor idler, you have probably reviewed various websites and centers. One of the most important factors in choosing conveyor rollers is paying attention to quality factors. In this regard, Avangard offers the following key points for optimal selection of conveyor rollers:

1- Attention to Technical Specifications:

For the selection of conveyor rollers, attention to their features and technical specifications is essential. Pipes with galvanized seams, steel, and other materials are usually used to make these rollers. The thickness and quality of the materials must meet standards to ensure the rollers have the capacity to bear sufficient weight and provide necessary resistance. Also, the type of frame and rollers should be chosen to adequately withstand the weight of materials and applied pressures.

2- Use of Standard Bearings:

Bearings play a central role in the functioning of conveyor rollers. The selection of standard and replaceable bearings is important due to their longevity and ease of maintenance and repair. High-quality bearings increase the useful life of the rollers and reduce maintenance costs.

3- Standard Welding and Machining:

The quality of welding, cutting, and machining of the rollers is very important. High-quality welds and precise cuts prevent the decline in rollers’ quality and performance. Additionally, springs used in rollers should have sufficient flexibility to withstand pressures and weights without damage.

4- Type of Load and Weight Range:

The type of load and weight range of products directly affects the choice of conveyor rollers. Gravity roller conveyors are suitable for objects with a flat base and light to medium weight, whereas more fragile loads or sensitive components require more advanced conveyor belts with greater precision.

5- Handling of Goods and Operational Environment:

Environmental conditions and specific operational needs should also be considered. For dusty, humid, or high-temperature environments, rollers resistant to harsh conditions are recommended. For precise operation and zero pressure, more advanced technology conveyors are suitable.

6- Price and Quality:

The price of conveyor rollers is determined based on factors such as body material, thickness, diameter, and application type. Low price may indicate the use of low-quality materials which can lead to premature roller damage. Balancing between price and quality is important for optimal selection.

7- Attention to Manufacturer:

Paying attention to the brand and manufacturer of the conveyor roller is very important. Reputable companies must comply with international standards like BS-GIS-FEM-AFONE-DIN-ISO-CEMA. Checking permits and standards can help ensure product quality and durability.

Considering these points, you can make an informed selection that meets your needs.

Selling Conveyor Rollers

The right conveyor roller guarantees smooth operation of your production line. For advice and purchase of various rollers, contact Avangard sales consultants.

Conveyor Roller Pricing

The price of conveyor rollers depends on various factors including roller material, dimensions, load capacity, surface coating type, and manufacturer brand. Additionally, the price of the conveyor drum, as one of the main components of the conveyor system, affects the overall system cost.

| Row | Description | Price |

| 1 | Price for Polymeric Roller | Contact Us |

| 2 | Price for Return Roller | Contact Us |

| 3 | Price for Press-Fitted and Standard Roller | Contact Us |

| 4 | Price for Replaceable Roller | Contact Us |

| 5 | Price for Metal Roller | Contact Us |

| 6 | Price for Aluminum Roller | Contact Us |

| 7 | Price for Steel Roller | Contact Us |

| 8 | Price for Cast Iron Roller | Contact Us |

| 9 | Price for Teflon Polymer Roller | Contact Us |

| 10 | Price for Guide Roller | Contact Us |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.