conveyor belt rubber

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

The conveyor belt rubber, also known as a rubber conveyor, is one of the essential components in solid material transportation systems across various industries. Designed for heavy load transfer over long distances with appropriate speed and efficiency, conveyor belt rubber with high resistance and durability can be used in many industries, including mining, food, pharmaceuticals, automotive, and many others. As the heart of transport systems, conveyor belt rubber is equipped with unique features tailored to the environmental conditions and specific needs of each industry, making its selection essential and crucial. Further, we will discuss more details about the features, applications, and types of conveyor belt rubber, and how to buy and sell it.

The conveyor belt rubber, or elevator rubber, due to its high resistance to abrasion, heat, and pressure, increases the effective lifespan of conveyor systems. Features such as flexibility and impact resistance make this product ideal for operation in harsh and challenging environments. Factors like the “price of conveyor belt rubber” and the “standard of conveyor belt rubber” are very influential in purchasing this product and selecting it.

Avangard Iran Company, the sales representative of various types of rubber conveyor belts (Rubber Conveyor Belt) in Tehran, is ready to offer services in various types and dimensions of conveyor rubber to you, dear customers. For consultation on prices, technical specifications, and catalog requests, please contact the technical consulting unit of Avangard.

Rubber Conveyor Belts

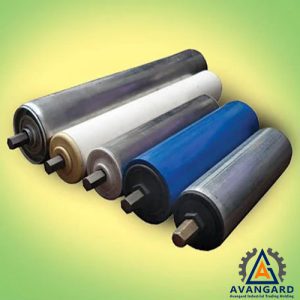

Rubber conveyor belts are composed of two main components: rubber and fabric. Fabric that is woven in warp and weft is placed in the middle layers of the belt and is responsible for increasing the tensile strength across its length and width. The material and structure of the fabric play a significant role in enhancing the tensile strength and durability of the belt. In these types of belts, the upper and lower layers are coated with rubber. The number of fabric layers can start from a single layer of fabric and two layers of rubber depending on the belt thickness. In fact, fabric layers enhance belt resistance, while the rubber layer increases resistance to wear and corrosion.

Role of Conveyor Belt Rubber

The term ‘conveyor belt’ is derived from two words: “tape” and “conveyor”. The word “tape” refers to a wide, open ring that operates flexibly, and “conveyor” refers to the ability to transfer objects. This system, also known as a conveyor belt, must have sufficient strength against tensile and bending forces to prevent tearing during object transport.

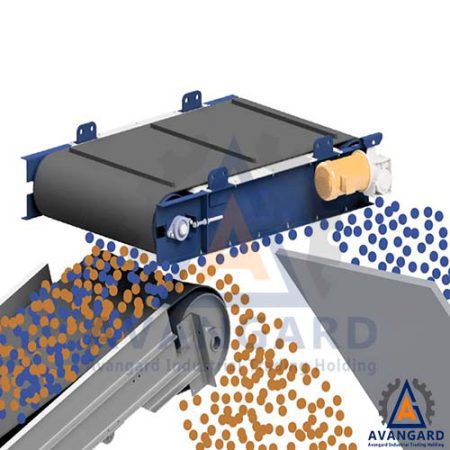

Conveyor systems operate using two drums or rollers that continuously rotate the belt around themselves. This process is facilitated by a set of hooks, gears, motors, gearboxes, and wide rubber belts. Additionally, the conveyor belt is guided along its path by a series of rollers.

Features of Conveyor Belt Rubber

Due to its excellent resistance to abrasion, heat, and chemicals, conveyor belt rubber is an ideal choice for use in heavy industrial environments. These rubbers, with their high flexibility, have the capability to bear heavy loads and effectively reduce system breakdowns. The standout features of this product include:

- Exceptional resistance to wear, tearing, and heat

- High flexibility and capability to bear heavy loads

- Resistance to chemicals and oils

- Proper adhesion to rollers

- High lifespan with less need for replacement

Applications of Conveyor Belt Rubber

Conveyor belt rubber plays an important role in material transfer in various industries such as mining, steel, cement, and agriculture. These rubbers, due to their high resistance to impact and pressure, are ideal for the transfer of heavy and massive materials such as stone, metals, and minerals. Also, due to their high durability, they are a suitable option for harsh and industrial environments. Some of the main applications of this product include:

- Transfer of minerals in mining industries

- Transport of food materials in the food industry

- Movement of industrial parts in factories

- Usage in automotive production lines

- Application in pharmaceutical and chemical industries

Types of Conveyor Belt Rubber

Conveyor belt rubbers are designed and produced in various types to best meet the needs of different industries. Each type of rubber has specific features that make it suitable for specific environmental conditions and transported materials. The following is a review of the types of conveyor belt rubbers:

1 – General-Purpose Conveyor Belt Rubber (EP)

This type of rubber is designed for general purposes and medium-weight material transfer. Its use is very common in various industries due to its durability and high efficiency.

2 – Heat-Resistant Conveyor Belt Rubber

Conveyors designed for the transfer of hot materials and use in high-temperature environments. This type of rubber is essential for industries with high-temperature production processes, such as cement, steel, and chemical industries. Materials moved in these industries can quickly wear down regular rubbers and damage equipment.

Using heat-resistant rubber in industries where extremely high temperatures are part of the production process is very important. In cement factories, steel plants, and recycling centers, the materials being transferred may reach temperatures that conventional plastics cannot withstand. These rubbers, by enduring heat, help maintain the conveyor’s performance and longevity, prevent production stoppages, and save losses and extra costs. Therefore, heat-resistant conveyor belt rubber not only protects equipment but also guarantees the productivity and stability of the production line.

3 – Oil and Grease-Resistant Conveyor Belt Rubber

In industries such as oil, gas, and automotive where oily and greasy materials are transferred, the use of oil-resistant rubber is necessary. This type of rubber resists corrosion caused by oily substances and has a long service life.

4 – Abrasion-Resistant Conveyor Belt Rubber

Abrasion-resistant conveyor belts are specifically designed for the movement of abrasive and rough materials. Due to their high resistance to continuous contact with hard materials such as stone and metals, this type of rubber is considered one of the best options for use in industries such as mining, cement plants, and crushers. Abrasion-resistant rubbers can provide greater durability and efficiency against erosion due to heavy and continuous impacts.

The conveyor belt in various industries, especially in the sand and gravel production industry, is a key tool for material movement. This device not only facilitates the material transfer process but also improves work safety. In industries where heavy and abrasive materials are transferred, the conveyor belt rubber is under significant pressure and damage. Therefore, choosing a suitable and high-quality rubber is crucial since it directly affects the efficiency and useful life of the conveyor belt.

In industries that move heavy and abrasive materials such as stone and sand, conveyor belt rubber quickly faces wear. Continuous contact of stones and materials with sharp edges accelerates its wear and erosion. Using abrasion-resistant conveyor belt rubber reduces the costs of frequent replacement while increasing conveyor belt durability and efficiency in high-stress environments. These rubbers, with high resistance to impact and pressure, are an ideal choice for factories and stone mines.

5 – Grip-Pattern Conveyor Belt Rubber

One specific type of conveyor belt rubber is the grip-pattern rubber, which has indentations and ridges that prevent material slippage on inclined paths. This type of rubber is ideal for industries that need to transfer materials at steep angles, such as transporting stones to crushers or shifting materials in large silos. Grip patterns ensure that the load moves without slipping, preventing potential damages caused by falling or sliding materials.

6 – Chemical-Resistant Conveyor Belt Rubber

These types of rubbers are designed for industries that transfer strong chemicals like acids, bases, and other corrosive substances. High resistance to chemical effects and damages from corrosive materials make chemical-resistant conveyor belt rubbers suitable options for chemical industries and some mines. These rubbers have a longer lifespan and are more resistant to corrosion from chemical contact.

Structure of Fabric-Corded Rubber Conveyor Belts

The fabric cores in rubber conveyor belts enhance belt strength and resistance against tensile and compressive stresses encountered during material transfer. These cores can be designed as single or multiple layers specified by tensile strengths such as EP-100, EP-125, EP-160, EP-400, and other standards.

Fabric conveyor belts, also known as EP belts, have a structure made of woven polyester with radial dacron and polyamide wefts. These belts perform well due to their low radial stretch, high grooveability, and good water resistance. The EP belts maintain their strength in wet conditions and resist mold growth due to their robust structure. Additionally, they feature a high initial modulus, which contributes to optimal performance in industries.

EP rubber conveyor belts, due to the use of specific chemical materials, are typically used in industries like mining, stone, cement, and metals and are not used in sectors related to food and pharmaceuticals. These belts are available in plain styles for flat lines and ribbed styles for inclined lines. In ribbed belts, the height of the ribs varies from 5 to 15 millimeters depending on the type of transported materials. For steep inclines, T-shaped step belts are used, and curtain walls are employed to prevent material spillage from the sides.

EP belts, due to their low warp elongation and suitable weft grooving ability, are very suitable for transferring materials over medium to long distances, heavy loads, and high-speed conditions. Next, we will discuss the technical specifications of different types of rubber conveyor belts.

1- Fabric in Multi-Layer EP Conveyor Belt

The EP conveyor belt is made from a combination of polyester and polyamide woven in warp and weft across the belt. This fabric, composed of one or more layers of polyester and polyamide (nylon) fibers, is protected by a thin adhesive rubber layer. This structure creates high resistance to abrasion and pressure.

2- Upper Rubber Coating

The upper layer of the conveyor belt holds special significance due to direct contact with materials. The type of upper coating, which can be resistant to abrasion, oil, heat, cold, and other factors, determines the grading of the conveyor belt.

3- Lower Rubber Coating

The lower layer of the conveyor belt, due to direct contact with conveyor system equipment (such as drums, drive pulleys, and idlers), protects the fabric layers against potential damage and pressure. This layer usually has a thinner thickness compared to the upper layer due to the lack of direct contact with transported materials.

4- Protective Edges

The edges of the conveyor belt help protect the principal layers against damage and environmental factors, extending the belt’s lifespan and preventing material leakage from the sides.

Upper and Lower Rubber Coating of Rubber Conveyor Belts

The upper and lower rubber coatings of rubber conveyor belts are designed according to the following standard to increase the belt’s resistance against harmful factors such as abrasion, corrosion, and impact. These coatings are aimed at increasing the belt’s durability and efficiency and are offered according to international standards to ensure optimal performance under various industrial conditions.

| Abrasion Resistance (MM3) | Elongation Percentage | Tensile Strength (MPA) | Coating Type | |

| 90 | 400 | 18 | W(DIN 22102) | AA |

| 120 | 450 | 25 | X(DIN 22102) | A |

Dimensional Specifications of EP Rubber Conveyor Belts

Conveyor Belt Width

The width of the conveyor belt is usually measured in millimeters.

Type of Fabric Core in Conveyor Belt Rubber

The EP conveyor belt is made from two types of fabric cores, polyester (E) and polyamide (P), which have high pressure and tensile resistance.

Number of Conveyor Belt Rubber Layers

The number of layers in a conveyor belt refers to its overall strength. However, more layers do not always mean greater resistance. For instance, a conveyor belt EP630/2 (with 2 layers of fabric) might have higher resistance compared to an EP500/3 (with 3 layers of fabric).

Thickness of Conveyor Belt Rubber

The thickness of the conveyor belt is obtained from the combination of the thickness of the upper and lower rubber layers along with the fabric core in its structure.

Technical Specifications of EP Rubber Conveyor Belts

| Technical Specifications of EP Rubber Conveyor Belts | |||||||

| Type | Standard | Minimum Tensile Strength (MPa) | Minimum Elongation (%) | Maximum Abrasion (mm) | Density (g/cm³) | Raw Materials | Temperature (°C) |

| Versatile Belt | |||||||

| P | MFH-13 | 10 | 300 | 250 | 1.26 | SBR | -45 to +60 |

| N | DIN22102N | 17 | 1400 | 1150 | 11.13 | SBR | -45 to +60 |

| ISO 10247L | |||||||

| BS 10247D | |||||||

| W | DIN22102W | 18 | 400 | 90 | 1.12 | NRBR | -60 to +60 |

| ISO 10247D | |||||||

| V | DIN22102Y | 20 | 400 | 150 | 1.13 | IR/SBR | -45 to +60 |

| X | DIN 22102X | 25 | 450 | 120 | 1.11 | NR | -45 to +60 |

| ISO 10247H | |||||||

| BS 490 M24 | |||||||

Structural Specifications of EP Rubber Conveyor Belts

| Length (m) | Width (mm) | Coating Thickness (mm) | Series Strength (N/mm) | Layer Thickness (mm/pressure) | Fabric Specifications | Fabric Structure | ||||||

| Lower | Upper | 6 Layers | 5 Layers | 4 Layers | 3 Layers | 2 Layers | Weft | Warp | ||||

| ≤300 | 400 to 2500 | 0 to 4.5 | 1.5 to 12 | 480 | 400 | 320 | 240 | 160 | 0.6 | Ep 80 | Polyamide (P) | Polyester |

| 500 to 2500 | 600 | 500 | 400 | 300 | 200 | 0.75 | Ep 100 | (EP) | ||||

| 900 | 750 | 600 | 450 | 300 | 1 | Ep 150 | ||||||

| 1200 | 1000 | 800 | 600 | 400 | 1.1 | Ep 200 | ||||||

| 1500 | 1250 | 1000 | 750 | 500 | 1.25 | Ep 250 | ||||||

| 1800 | 1500 | 1200 | 900 | 600 | 1.35 | Ep 300 | ||||||

| 800 to 2500 | 2100 | 1750 | 1400 | 1050 | – | 1.45 | Ep 350 | |||||

| 2400 | 2000 | 1600 | – | – | 1.55 | Ep 400 | ||||||

| 100 to 2500 | 3000 | 2500 | 2000 | – | – | 1.7 | Ep 450 | |||||

| Adhesive Strength | Belt Core | |||||||||||

| Longitudinal Stretch at Return | Longitudinal Stretch at Break | Between Rubber and Carcass (Newton/mm) | Between | |||||||||

| Rubber Thickness > 1.5 | ≤1.5 mm | |||||||||||

| Rubber Thickness ≤1.5 mm | ||||||||||||

| 2 | 10 | ≥3.50 | ≥3.15 | ≥4.50 | Polyester EP | |||||||

What is the Tensile Strength or EP of Conveyor Belts?

In conveyor belts, tensile strength or EP refers to the use of polyester fibers (E) and polyamide or nylon fibers (P) in the belt’s structure. Polyester fibers are placed as warp in the longitudinal direction, and polyamide or nylon fibers are placed as weft in the transverse direction of the conveyor belt. This combination increases the belt’s resistance to tearing, pressure, chemicals, moisture, abrasion, and cutting. Additionally, these properties give the belt high flexibility, low elongation, and lightweight characteristics.

The calculated tensile strength equals the force required to break the belt, which is equivalent to ten times its tensile capacity. In other words, the tensile strength of the conveyor belt is obtained by multiplying the number of fabric layers in the belt by the tensile strength of each layer (equivalent to 200 Newtons per millimeter).

Features of EP Conveyor Belt

- High efficiency in material transfer

- Exceptional safety features

- Resistance to wear, impact, and corrosion

- Very high tensile strength while being lightweight

- Soft body with excellent flexibility and suitable indentation

- Strong adhesion between fabric layers and rubber

Application of EP Rubber Conveyor Belt

EP rubber conveyor belts are particularly suitable for transporting bulk, granular, and powdery materials at normal temperatures and in non-corrosive conditions. These belts are widely used in the following industries:

1- Gypsum, clay, and limestone mines: Suitable for moving minerals with diverse characteristics.

2- Sand and stone industry: Ideal for transporting constructional and mineral materials.

3- Power plants and recycling and incineration facilities: Resistant to harsh conditions and various materials.

4- Cement and concrete industry: Suitable for transporting materials in cement and concrete production processes.

5- Mineral production plants and other similar industries: Widely used in the transport and transfer of various mining materials and crushers.

Conveyor Belt Rubber in Crushers

The use of conveyor belt rubber in crushers is one of the main factors in improving the performance of material handling systems. These rubbers are used for several reasons such as preventing material slippage, enhancing durability and conveyor belt lifespan, and improving material adhesion to the conveyor belt. Special conveyor belt rubbers used in crushers need to have specific properties to withstand harsh environments and extensive abrasion due to constant contact with heavy and hard materials.

Advantages of Using Conveyor Belt Rubber in Crushers

- Prevents material slippage: Increases friction to prevent slippage during transport.

- Enhances conveyor belt durability: Made from wear and corrosion-resistant materials, thereby increasing belt lifespan.

- Improves conveyor performance: Quality rubbers boost performance and productivity while reducing failures from pressure and heavy materials.

- Resists specific environmental conditions: Must withstand high temperatures, moisture, and dust.

Features of Conveyor Belt Rubber in Crushers

- Wear resistance: Highly resistant to the wear caused by direct contact with rocks and minerals.

- High pressure tolerance: Must bear high pressure and repeated impacts from falling and striking rocks.

- Heat and chemical resistance: Must withstand high temperatures or specific chemicals.

Application of Conveyor Belts in Sand and Gravel Production Industry

In the sand and gravel production industry, due to the high weight of stones and high output, conveyor belts are used for material transport. The rubber of the conveyor belt in this industry must be of high quality to withstand significant pressure and weight. Using conveyor belts increases material transfer speed and prevents product damage during transport.

Why is Using Suitable Conveyor Belt Rubber in Crushers Important?

- Reduces maintenance costs: High-quality rubbers decrease the need for frequent replacements, minimizing maintenance expenses.

- Increases conveyor system efficiency: Durable and high-quality rubbers enhance crushing operations efficiency and reduce unnecessary downtimes.

- Improves work safety: Suitable conveyor belt rubbers reduce material slippage, ensuring safety for personnel and machinery.

Purchasing Conveyor Belt Rubber

When purchasing conveyor belt rubber, consider factors such as quality, application type, and price. Selecting the right rubber based on the type of material being conveyed, environmental conditions, and load capacity is very important. Also, determining the belt dimensions and length according to project needs is crucial. Avangard’s sales specialists are ready to provide expert advice to help you choose the best conveyor belt rubber. For consultation and more information, contact Avangard’s experts.

A Few Top Brands of Rubber Conveyor Belts or Conveyor Rubber Manufacturers

| Tsubaki Rubber Conveyor Belt | Hungsbelt Rubber Conveyor Belt |

|

|

| Unipower Rubber Conveyor Belt | Tempo Rubber Conveyor Belt |

|

|

| Steinhaus Rubber Conveyor Belt | Continental Rubber Conveyor Belt |

|

|

| Habasit Rubber Conveyor Belt | Vecoplan Rubber Conveyor Belt |

|

|

| Unichains Rubber Conveyor Belt | Eurobelt Rubber Conveyor Belt |

|

|

| Esbelt Rubber Conveyor Belt | Niko Rubber Conveyor Belt |

|

|

| Phoenix Rubber Conveyor Belt | Komplet Rubber Conveyor Belt |

|

|

| Jovisa Rubber Conveyor Belt | Ashland Rubber Conveyor Belt |

|

|

| Graf Rubber Conveyor Belt | Sempertrans Rubber Conveyor Belt |

|

|

| Stricker Rubber Conveyor Belt | Roulunds Rubber Conveyor Belt |

|

|

Conveyor Belt Rubber Sales

Avangard Company, with extensive experience in conveyor belt rubber sales, offers high-quality products in compliance with international standards. These products are sold both wholesale and retail, allowing customers to order the appropriate conveyor belt rubber according to their needs.

- Offering a variety of conveyor belt rubbers with excellent quality and reasonable prices

- Ability to produce custom belts based on customer needs

- Guaranteed quality and durability of products

Conveyor belt rubbers are produced in various grades to meet diverse industrial needs. Below, a table of different conveyor belt rubber grades is provided to assist you in making a simpler and more reliable purchase.

| Grade | Y | X | W | WH | WH | SUPER WL |

| Characteristic and application | With high abrasion-resistant cover | With high abrasion-resistant cover | With high abrasion-resistant cover | For material transport | For material transport | For material transport |

| Abrasion | 130MM3 > | 120MM3 > | 90MM3 > | 90MM3 > | 55MM3 > | 35MM3 > |

| Hardness | 60 +/- 5 Sh°A | 65 +/- 5 Sh°A | 62 +/- 5 Sh°A | 75 +/- 5 Sh°A | 62 +/- 5 Sh°A | 62 +/- 5 Sh°A |

| Operating temperature | -50°C … +60°C | -50°C … +60°C | -50°C … +60°C | -50°C … +60°C | -50°C … +60°C | -50°C … +60°C |

Conveyor Belt Rubber Price

The price of conveyor belt rubber depends on various factors including type, dimensions, thickness, and its specific features. Generally, heat-resistant and abrasion-resistant rubbers usually have a higher price. For precise and up-to-date pricing, contact the sales experts at Avangard Company to get the best offers.

We apologize, all prices are currently being updated. Please contact the sales department for exact pricing inquiries.

| No. | Product Description | Price |

| 1 | Conveyor Belt Rubber Price 65cm Width Taiwan 6mm / 2 Ply Yarn / ep200 | Contact |

| 2 | Conveyor Belt Rubber Price 65cm Width Taiwan 10mm / 4 Ply Yarn / ep500 | Contact |

| 3 | Conveyor Belt Rubber Price 65cm Width Turkey 10mm / 4 Ply Yarn / ep500 | Contact |

| 4 | Conveyor Belt Rubber Price 65cm Width Taiwan Ribbed / 4 Ply Yarn / ep500 | Contact |

| 5 | Conveyor Belt Rubber Price 80cm Width Taiwan 6mm / 2 Ply Yarn / ep200 | Contact |

| 6 | Conveyor Belt Rubber Price 80cm Width Taiwan 10mm / 4 Ply Yarn / ep500 | Contact |

| 7 | Conveyor Belt Rubber Price 80cm Width Turkey 10mm / 4 Ply Yarn / ep500 | Contact |

| 8 | Conveyor Belt Rubber Price 80cm Width Korean 10mm / 4 Ply Yarn / ep500 | Contact |

| 9 | Conveyor Belt Rubber Price 80cm Width Taiwan 13mm / 4 Ply Yarn / ep800 | Contact |

| 10 | Conveyor Belt Rubber Price 80cm Width Turkey 13mm / 4 Ply Yarn / ep800 | Contact |

| 11 | Conveyor Belt Rubber Price 80cm Width Sahand 10mm / 3 Ply Yarn / ep315 | Contact |

| 12 | Conveyor Belt Rubber Price 80cm Width Sahand 10mm / 4 Ply Yarn / ep400 | Contact |

| 13 | Conveyor Belt Rubber Price 80cm Width Dena 10mm / 4 Ply Yarn / ep400 | Contact |

| 14 | Conveyor Belt Rubber Price 80cm Width Taiwan Ribbed / 4 Ply Yarn / ep500 | Contact |

| 15 | Conveyor Belt Rubber Price 80cm Width Turkey Ribbed / 4 Ply Yarn / ep500 | Contact |

| 16 | Conveyor Belt Rubber Price 100cm Width Taiwan 6mm / 2 Ply Yarn / ep250 | Contact |

| 17 | Conveyor Belt Rubber Price 100cm Width Taiwan 10mm / 4 Ply Yarn / ep500 | Contact |

| 18 | Conveyor Belt Rubber Price 100cm Width Turkey 10mm / 3 Ply Yarn / ep500 | Contact |

| 19 | Conveyor Belt Rubber Price 100cm Width Taiwan 13mm / 4 Ply Yarn / ep800 | Contact |

| 20 | Conveyor Belt Rubber Price 100cm Width Sahand 10mm / 3 Ply Yarn / ep400 | Contact |

| 21 | Conveyor Belt Rubber Price 100cm Width Dena 10mm / 3 Ply Yarn / ep315 | Contact |

| 22 | Conveyor Belt Rubber Price 100cm Width Taiwan Ribbed 10mm / 4 Ply Yarn / ep500 | Contact |

| 23 | 3 Meter Conveyor Belt Rubber Price | Contact |

| 24 | Corrugated Conveyor Belt Rubber Price | Contact |

| 25 | Conveyor Belt Price | Contact |

| 26 | Conveyor Belt Rubber Price 80 Width | Contact |

| 27 | Conveyor Belt Rubber Price 60 Width | Contact |

| 28 | 12 Meter Conveyor Belt Price | Contact |

| 29 | Conveyor Belt Rubber Price | Contact |

| 30 | Conveyor Belt Rubber Sale | Contact |

| 31 | 6 Meter Conveyor Belt Price List | Contact |

| 32 | Buy Conveyor Belt Rubber | Contact |

| 33 | Conveyor Belt Sander Rubber | Contact |

| 34 | Crusher Conveyor Belt Rubber | Contact |

| 35 | Ribbed Conveyor Belt Rubber | Contact |

| 36 | Isfahan Conveyor Belt Rubber | Contact |

| 37 | Dena Conveyor Belt Rubber | Contact |

| 38 | Sahand Conveyor Belt Rubber | Contact |

| 39 | Second-hand Conveyor Belt Rubber for Sale | Contact |

| 40 | Taiwan Conveyor Belt Rubber | Contact |

| 41 | Turkey Conveyor Belt Rubber | Contact |

| 42 | EP315/3 Conveyor Belt Rubber | Contact |

| 43 | EP400/4 Conveyor Belt Rubber | Contact |

| 44 | EP500/4 Conveyor Belt Rubber | Contact |

| 45 | EP630/3 Conveyor Belt Rubber | Contact |

| 46 | EP-100/1 Rubber Conveyor Belt Price | Contact |

| 47 | EP-200/1 Rubber Conveyor Belt Price | Contact |

| 48 | EP-315/2 Rubber Conveyor Belt Price | Contact |

| 49 | EP-315/3 Rubber Conveyor Belt Price | Contact |

| 50 | EP-400/2 Rubber Conveyor Belt Price | Contact |

| 51 | EP-400/3 Rubber Conveyor Belt Price | Contact |

| 52 | EP-500/3 Rubber Conveyor Belt Price | Contact |

| 53 | EP-500/4 Rubber Conveyor Belt Price | Contact |

| 54 | EP-630/3 Rubber Conveyor Belt Price | Contact |

| 55 | EP-630/4 Rubber Conveyor Belt Price | Contact |

| 56 | EP-800/4 Rubber Conveyor Belt Price | Contact |

| 57 | EP-1000/4 Rubber Conveyor Belt Price | Contact |

| 58 | EP-1250/4 Rubber Conveyor Belt Price | Contact |

| 59 | EP-1600/4 Rubber Conveyor Belt Price | Contact |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.