Bucket Elevator

ویژگی های محصول:

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

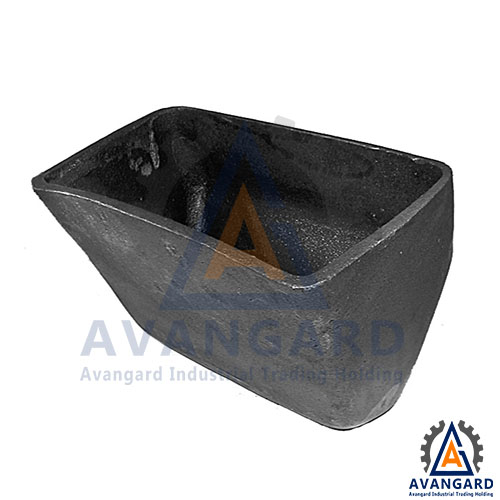

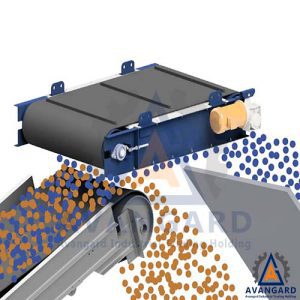

What is a Bucket Elevator?

A bucket elevator or elevator bucket (elevator cup) is an essential component in vertical material conveying systems, playing a vital role in elevating materials from one point to a higher one. These components are manufactured in various shapes and materials and are used in diverse industries such as cement, steel, food, chemical, and mining. Selecting the appropriate bucket elevator depends on factors like the type of material, capacity, desired height, and environmental conditions. These components, designed to increase efficiency and reduce operational costs in vertical material handling systems, are sometimes used alongside conveyor belts. Avangard offers various bucket elevators with the highest quality standards and competitive prices. To purchase a bucket elevator and get advice on the best choice for your needs, contact Avangard’s sales experts.

Features of Bucket Elevators

- Material: Buckets are usually made of steel, cast iron, or plastic. The choice of material depends on the type of transferred material, wear and corrosion resistance, and environmental conditions.

- Shape: Buckets are produced in different shapes such as cylindrical, cubic, oval, etc. The shape depends on the type of material and method of discharge.

- Capacity: The bucket capacity is determined based on the volume of material that needs to be lifted each cycle.

- Connections: Buckets are attached to the elevator chain or belt, and the connection type depends on the system design and material type.

Types of Bucket Elevators

Metal Buckets

Metal bucket elevators or material elevator cups are key components in various industries like cement, petrochemical, chemical, mining, and steel. These metal buckets are produced in both pressed and welded varieties. Pressed cans, also known as Columbus cans, are seamless and suitable for most materials. The stainless steel construction is particularly popular in the food industry.

Typically, buckets with a thickness up to 2mm and smaller dimensions are produced as pressed and for thicker sheets and larger dimensions as welded. When these buckets are used for transporting abrasive or hard materials, their edges are made from abrasion-resistant or Hardox sheets and are doubled for greater resistance.

These buckets come in a variety of sizes including 10, 14, 16, 20, 25, and 30 cm, and with 2, 3, or 4 holes. Custom manufacturing for specific sizes and designs is also available. Stainless elevator cups are also very suitable for transporting wet, chemical, and food industry materials.

Types of Metal Conveyor Belt Elevator Cups or Metal Elevator Buckets

| Types of Metal Buckets | Specifications and Applications | Advantages | Disadvantages |

| Columbus Metal Bucket | Classic design, suitable for medium-density materials, widely used in various industries | Simple structure, reasonable price, easy maintenance | Less resistance to wear and corrosion compared to some other models |

| Welded DIN Metal Bucket | Made from welded steel sheets, customizable, suitable for heavy loads | High strength, large load capacity, adjustable for various materials | Higher manufacturing cost, weld seams can be contamination points |

| Starco Steel Metal Bucket | Engineered design, high wear and corrosion resistance, suitable for corrosive environments | Long lifespan, excellent performance in harsh conditions, impact resistance | Higher price than standard models |

| Pelican Steel Metal Bucket | Strong and robust structure, suitable for large and irregularly shaped materials | High load capacity, impact and wear resistance, long lifespan | Heavy weight, relatively high price |

| Di-Max Ductile Metal Bucket | Made from ductile iron pipes, suitable for small and medium-sized materials | High flexibility, impact resistance, lighter weight compared to sheet models | Lower load capacity compared to sheet models, higher price |

| Bottomless Metal Bucket | Without a bottom, suitable for fine and powdery materials | Prevents clogging, complete discharge, suitable for sticky materials | Requires more care in installation and maintenance, may cause material spillage |

Additional Information for Types of Metal Buckets

- Columbus: This is one of the oldest and most well-known bucket types and remains widely used in many industries due to its simple structure and reasonable price.

- Welded DIN: This type is highly customizable and can be designed and manufactured to meet specific project needs.

- Starco Steel and Pelican Steel: These two models are suitable for heavy-duty applications and corrosive environments due to their high resistance and lifespan.

- Di-Max Ductile: This model is suitable for transferring small and medium-sized materials and in confined spaces due to its high flexibility.

- Bottomless: This model is used to transport fine and powdery materials and prevent system clogs.

Plastic Buckets

Plastic buckets or plastic cups are considered a new generation of elevator buckets. This model is designed for lighter tasks and is noteworthy due to its lower cost and higher efficiency in material handling elevators. These buckets have extensive applications, especially in hygienic, food, and pharmaceutical industries. Distinguishing features include low weight, easy production in high quantities, and moisture resistance.

Comparison of Different Types of Impact Resistant and Abrasion Resistant Plastic Elevator Buckets

| Bucket Type | Special Features | Applications | Advantages | Disadvantages |

| Normal Plastic Bucket | Simple design, affordable price | Low-density materials, medium capacity | Reasonable price, mass production | Less resistance to wear and impact |

| CCS Plastic Bucket | Optimized design for reducing friction, suitable for fluid materials | Reduces energy consumption, increases belt lifespan | Higher price than normal model | More sensitive to abrasive materials |

| Z Plastic Bucket | Curved design, suitable for large, irregularly shaped materials | Reduces material spillage, high capacity | Higher price, complex design | Not suitable for all material types |

| Septated Plastic Bucket | Inner partitions for material separation, suitable for mixed materials | Prevents material mixing, suitable for sensitive materials | Higher price, complex manufacturing | Lower capacity compared to other models |

| BR & AF Impact and Abrasion Resistant Plastic Bucket | Made of highly durable polyurethane materials reinforced with fibers | Very high resistance to wear, impact, and chemicals, long lifespan | Much higher price, heavier weight | Suitable for very harsh working conditions |

Additional Descriptions for Impact Resistant and Abrasion Resistant Plastic Buckets

- Normal Bucket: This type is the simplest and most common plastic bucket suitable for general purposes.

- CCS Bucket: The special design of this bucket reduces friction between materials and the bucket, resulting in lower energy consumption and longer belt lifespan.

- Z Bucket: The curved shape of this bucket ensures easy material flow and prevents spillage.

- Septated Bucket: Used for separating different materials and preventing their mixing.

- BR & AF Bucket: Made from high-strength polyurethane materials, suitable for abrasive material transfer and harsh work conditions.

Factors Affecting Bucket Type Selection:

- Material Type: The type, particle size, density, and other physical properties of the material influence the bucket model selection.

- Conveying Capacity: The required capacity for each transfer cycle determines the size and type of bucket.

- Elevation Height: The height to which materials need to be elevated affects the bucket design and material.

- Environmental Conditions: Temperature, humidity, and the presence of corrosive and abrasive materials in the environment influence the bucket’s material and coating choice.

- Conveying Speed: The required material transfer speed affects the bucket design and dimensions.

- Budget: The price of each bucket type varies based on raw materials, design, and manufacturing complexity.

Overall Advantages of Impact Resistant and Abrasion Resistant Plastic Buckets:

- High Wear and Impact Resistance: Longer lifespan and reduced maintenance costs

- Corrosion Resistance: Suitable for corrosive environments

- Lightweight: Reduced load on motor and belt

- Thermal Insulation: Suitable for transferring hot or cold materials

- Hygiene and Safety: Smooth and non-porous surface, preventing bacterial growth

Comparative Table of Metal Buckets with Plastic Buckets

| Plastic Bucket | Metal Bucket | Feature |

| Polymer (like polypropylene, polyethylene) | Steel, Cast Iron | Material |

| Low | High | Wear Resistance |

| High (depending on polymer type) | High | Corrosion Resistance |

| Low to Medium | High | Impact Resistance |

| Light | Heavy | Weight |

| Lower | Higher | Price |

| Shorter | Longer | Lifespan |

| Light, non-abrasive materials, food, pharmaceuticals | Heavy, abrasive, hot materials | Application |

| Average | High | Working Temperature |

| Plastic | Metal | Appearance |

| Less maintenance needed | Requires periodic maintenance | Maintenance |

Applications of Bucket Elevators

- Cement Industry: For transferring raw materials like limestone, clay, and shale

- Steel Industry: For transferring raw materials like iron ore, coal, and lime

- Food Industry: For transferring food materials like grains, flour, and sugar

- Chemical Industry: For transferring chemicals like fertilizers, detergents, and pigments

- Mining Industry: For transferring minerals like ore and ash

Bucket Elevator Nuts and Bolts

Bucket elevator bolts are key components in installing and connecting buckets to the elevator body. These bolts, often made of high-quality steel, have a special design known as two-lug or multi-lug head. This design provides a secure fastening that prevents damage to the bucket or the elevator belt.

These bolts are produced in various sizes and pitches, and the choice of suitable bolts depends on the bucket type and dimensions. The number of bolts needed for each bucket connection is determined by the bucket size and type. Using the correct bolts and ensuring their proper installation is crucial to prevent issues such as bucket loosening or belt damage. Correct selection and precise installation of these bolts can significantly enhance the efficiency and service life of the material conveying system. These bolts are manufactured in a wide range of sizes, from 6mm to 14mm in diameter and 2cm to 7cm in length.

Buying Bucket Elevators:

When purchasing suitable buckets, consider factors such as the type of material conveyed, transfer capacity, lifting height, environmental conditions, and budget. It is recommended to contact Avangard’s sales experts for advice on the best option for your needs.

Selling Bucket Elevators:

Avangard offers a variety of bucket elevators of high quality and reasonable price. The company’s products are manufactured using high-quality raw materials and state-of-the-art technology, meeting the required quality standards.

Bucket Elevator Prices:

Bucket elevator prices depend on various factors such as material, dimensions, capacity, connection type, and quantity. For exact product pricing, contact Avangard’s sales experts.

| No. | Product Description | Price |

| 1 | Price of Columbus Metal Bucket | Contact for Price |

| 2 | Price of Welded DIN Metal Bucket | Contact for Price |

| 3 | Price of Starco Steel Metal Bucket | Contact for Price |

| 4 | Price of Pelican Steel Metal Bucket | Contact for Price |

| 5 | Di-Max Ductile Metal Bucket | Contact for Price |

| 6 | Price of Bottomless Metal Bucket | Contact for Price |

| 7 | Price of Normal Plastic Bucket | Contact for Price |

| 8 | Price of CCS Plastic Bucket | Contact for Price |

| 9 | Price of Z Plastic Bucket | Contact for Price |

| 10 | Price of Septated Plastic Bucket | Contact for Price |

| 11 | Price of Impact Resistant and Abrasion Resistant Plastic Bucket AF | Contact for Price |

| 12 | Price of Impact Resistant and Abrasion Resistant Plastic Bucket BR | Contact for Price |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.