[rank_math_breadcrumb]

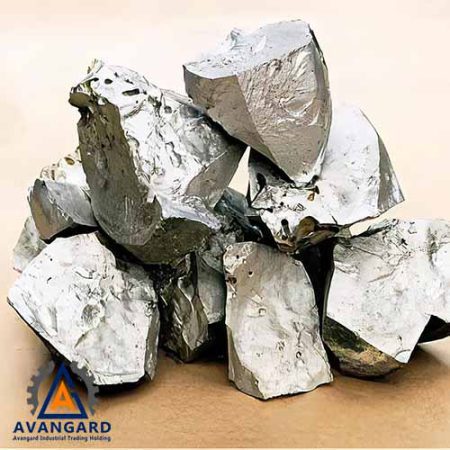

Noble and Major Ferroalloys

The use of ferroalloys in metal industries is to improve the physical and chemical properties of metals, increase strength, corrosion resistance, and other properties related to steel production. These alloys are used as additives in the production of steel and more. Common ferroalloys include ferromolybdenum, ferrosilicon, ferrotitanium, ferrotungsten, ferroboron, ferrovanadium, ferroniobium, ferrophosphorus, ferrochrome, ferromanganese, ferrosilico calcium, ferrosilico manganese, ferrosilico magnesium, and ferrosilico zirconium. For purchasing, production, and pricing of various noble and major ferroalloys, contact the sales experts of Avangard Holding.

What is a Noble Ferroalloy?

A noble ferroalloy refers to a combination of iron with other specific elements. These alloys typically include iron along with one or more other elements such as molybdenum (MO), boron (B), titanium (Ti), tungsten (W), niobium (Nb), and vanadium (V). Noble ferroalloys refer to alloys that contain precious and valuable metals. These alloys usually include precious metals like gold, silver, platinum, and rhodium. These alloys have very high value due to the unique physical and chemical properties derived from precious metals. The use of these metals in alloys as noble ferroalloys usually helps in producing high-value and high-quality products.

What is a Major Ferroalloy?

A major ferroalloy is a combination of iron with elements such as silicon, phosphorus, calcium, magnesium, manganese, zirconium, and chromium. This type of ferroalloy is widely used in the steelmaking and casting of steel and cast iron. The most important applications of this type of ferroalloy include degassing, alloying, improving mechanical properties, and the strength of steel and cast iron products.

Types of Noble and Major Ferroalloys

1. Ferromolybdenum

Ferromolybdenum is a type of ferroalloy made of iron (Fe) and molybdenum (Mo). This ferroalloy is commonly used as an additive in the steel industry. As an alloying element, molybdenum adds properties such as increased strength, corrosion resistance, and heat resistance to steel. Ferromolybdenum, as a source of molybdenum in steel, enables the improvement of metal properties and increases their efficiency. This alloy is particularly used in the production of corrosion and wear-resistant steels and steels that need to withstand high temperatures. Ferromolybdenum has different amounts of molybdenum, and this percentage is usually determined based on the specific needs of the steel and the production process.

2. Ferrotitanium

Ferrotitanium is a type of ferroalloy made of iron (Fe) and titanium (Ti). Titanium is a light, resistant, high-strength, and corrosion-resistant metal used in various industries to produce parts with specific characteristics. As a strategic metal, titanium is used in many fields due to its unique properties. The use of titanium is common in aerospace, automotive, marine, medical (such as medical implants), sports (such as manufacturing sports equipment), oil and gas, and chemical industries. Titanium is considered a suitable alternative to other metals in many environments due to its lightness, corrosion resistance, high mechanical properties, and heat resistance.

3. Ferroniobium

Ferroniobium means a ferroalloy containing the element niobium (Nb). Niobium is a metallic element that is located in the periodic table with the symbol Nb and atomic number 41. This metal is resistant and has high strength. Ferroniobium may be used in various industries, especially in the production of materials that need resistance to heat and corrosion. This metal is used in aerospace, nuclear technology, the electronics industry, as well as in the manufacturing of steel materials and the production of heat and corrosion-resistant alloys.

4. Ferrovanadium

Ferrovanadium may be used as an alloy or in pure form for various purposes. Vanadium alloys, especially using iron and steel, increase mechanical properties and corrosion resistance. Also, the metal vanadium is used in the petrochemical industry, aerospace, and the production of cutting and drilling tools. Vanadium is a metallic element located in the periodic table with the symbol V and atomic number 23. Due to its resistance to corrosion and heat, vanadium is used in various industries, and in some cases, this ferroalloy is used in cast iron to increase its anti-wear properties.

5. Ferrotungsten

Ferrotungsten is mainly supplied in the form of powder, strip, or tube and is used in various industries including electronics, construction, the production of cutting and drilling tools, and aerospace. Tungsten is also used as a structural material in the construction of electronic devices. Tungsten is a metallic element located in the periodic table with the symbol W and atomic number 74. Due to its special properties, including a very high melting point, hardness, resistance to heat, and corrosion resistance, this metal is used in various applications.

6. Ferroboron

Ferroboron is mainly used in the market as mineral boron or boron compounds. Boron is a chemical element with the symbol B and atomic number 5. This element is sold in various forms of compounds such as borax, boric acid, and other boron compounds. Boron and its compounds have a wide range of applications in various industries, including glassmaking, the paper industry, the fertilizer industry, electronics, and the chemical industry. Boron is also used as an important element in the production of galvanizing (boraxide).

7. Ferrosilicon

Ferrosilicon is one of the important raw materials in the metals and metallurgy industry. Silicon, with the elemental symbol Si, is from group 14 of the periodic table and is widely used in various industries. This element is commonly used as an alloy in the production of steel and other metals.

Applications of silicon in industry include:

1. Steel Production: Adding silicon to iron improves its properties.

2. Aluminum Industries: In the production of aluminum, silicon is used as an alloying agent.

3. Metal Product Industries: Silicon is used in the production of alloys such as ferromanganese and ferrochrome, etc.

8. Ferrophosphorus

Ferrophosphorus means the supply or sale of phosphorus. This element exists in nature as phosphate and is used in various forms in different industries. Phosphorus is also one of the essential elements for the growth and development of plants and animals and plays an important role in biological processes.

9. Ferrosilicomanganese

Ferrosilicomanganese is one of the main metal alloys made of manganese and silicon. This alloy is often used as an additive in the casting and steelmaking industries. Silicomanganese is used as a source of silicon and manganese in the production of alloy steels and can help improve the physical and mechanical properties of steel.

10. Ferrosilicomagnesium

Ferrosilicomagnesium is a ferroalloy made of silicon and magnesium along with the metal iron. This ferroalloy is usually produced as a solid or granules and lumps. The two main elements in the composition, silicon and magnesium, have beneficial properties for adding to metals such as iron. The use of ferrosilicomagnesium is common in various industries, including steelmaking and casting. This ferroalloy is used as a reducing agent and to improve the physical properties of metals. Also, adding this ferroalloy to iron and steel improves mechanical properties, heat resistance, and other important features.

11. Ferrosilicocalcium

Ferrosilicocalcium is a ferroalloy made of silicon (Si) and calcium (Ca) along with the metal iron (Fe). This ferroalloy is usually produced in solid form or as granules. The use of ferrosilicocalcium as a reducing agent and additive to metals improves their physical and mechanical properties. Various industries, including steelmaking and casting, use this ferroalloy. Adding ferrosilicocalcium to iron and steel can help improve melting properties, reduce oxidation, increase heat resistance, and other important metal features.

12. Ferrosilicozirconium

Ferrosilicozirconium is a ferroalloy made of silicon (Si) and zirconium (Zr) along with the metal iron (Fe). The use of ferrosilicozirconium as a microalloying element in simple cast carbon steel leads to an increase in its hardness and impact toughness. This increase in hardness is especially noticeable after heat treatment. Various industries, including steelmaking and casting, use this ferroalloy. Other subgroups of noble and major ferroalloys include ferrochrome and ferromanganese, which have several types and are explained separately in their respective subgroups.

Related content: Cylindrical Exothermic Sleeves for Risers

Application of Major and Noble Ferroalloys

Ferroalloys have various applications in steelmaking, casting, automotive, aerospace, and other industries. These alloys are added to steel and cast iron to improve various properties. Below are some applications of ferroalloys in these industries:

1. Steelmaking Industry

- Increased strength

- Increased corrosion resistance

- Improved mechanical properties

- Increased heat resistance

- Increased fatigue resistance

- Increased hardness

- Stabilization of the structure

2. Casting Industry

- Alloying

- Nucleation

- Deoxidation

- Increased crack removal and stability of the crystal structure in steel castings

- Increased fluidity and degassing

- Production of stainless steel

3. Automotive Industry

- In the production of light and low-weight car parts as a substitute for heavy parts

- Production of high-strength and low-weight parts

4. Aerospace Industry

- In the construction of heat-resistant parts and light metals

Price of Major and Noble Ferroalloys

Please contact the sales experts at Avangard Company for the price list of noble ferroalloys and major ferroalloys.

| Row | Description | Price |

| 1 | Price of Ferrovanadium | Contact Us |

| 2 | Price of Ferroniobium | Contact Us |

| 3 | Price of Ferroboron | Contact Us |

| 4 | Price of Ferrotungsten | Contact Us |

| 5 | Price of Ferrotitanium | Contact Us |

| 6 | Price of Ferromolybdenum | Contact Us |

| 7 | Price of Ferrosilicon | Contact Us |

| 8 | Price of Ferrophosphorus | Contact Us |

| 9 | Price of Ferrosilico Manganese | Contact Us |

| 10 | Price of Ferrosilico Magnesium | Contact Us |

| 11 | Price of Ferrosilico Calcium | Contact Us |

| 12 | Price of Ferrosilico Zirconium | Contact Us |

Buying and Selling Noble Ferroalloys and Major Ferroalloys

Ferroalloys, as compounds of different elements, are used in various industries and help improve production processes. The quality and correct standard of these alloys are very critical and affect the quality and final result of metal products. For this reason, various industries that use metals containing ferroalloys must pay special attention to the purchase of their raw materials.

You must ensure that the raw materials used are from reputable companies and suppliers that are equipped with modern machinery and equipment and comply with international standards. This action is necessary due to the significant impact that the grade of final products in metal industries has on the standards and processes of raw material production. One of the top companies for buying ferroalloys is Avangard Company, which provides you with the best quality and reasonable prices. For buying and ordering various noble and major ferroalloys, contact the sales experts of Avangard Holding.

فارسی

فارسی  Arabic

Arabic