[rank_math_breadcrumb]

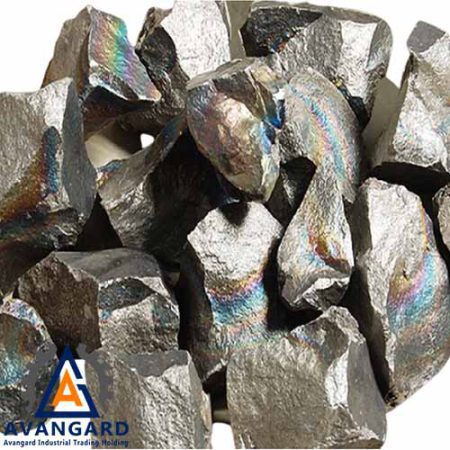

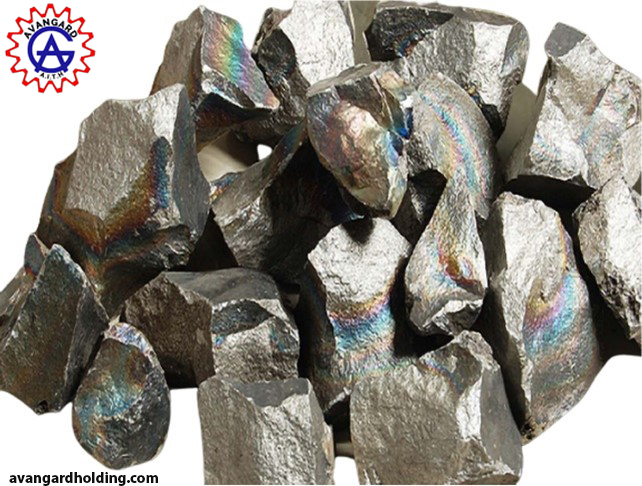

Ferromanganese

Ferromanganese is a ferroalloy mainly composed of iron and manganese, used to improve the properties of steel and cast iron. Ferromanganese alloy is primarily used in the industries of steelmaking and cast iron production. Ferromanganese is known as a wear-resistant alloy and is considered one of the modifying alloys for steels due to its mechanical properties, wear resistance, and the ability to form diverse alloys with other metals.

Ferromanganese plays a very important role as a main element in the production of manganese steel. This type of steel, by adding ferromanganese to the composition, increases resistance to rust and corrosion. The percentage of the composition of ferromanganese in steel may vary, but adding this element to steel improves its mechanical properties and corrosion resistance.

Ferromanganese is used as a widely used ferroalloy in industries that produce crusher parts (Hadfield steel), similar to ferrochrome alloy. This alloy can be added to cast iron depending on the amount of carbon, and it can improve its mechanical properties and wear resistance. Considering the importance of ferromanganese in industry, high-quality raw materials, buying and selling this alloy, and adjusting prices in industrial markets are considered important issues.

What is Ferromanganese?

Manganese is among the inexpensive alloying elements among other elements that improve important mechanical properties, including toughness and strength. This element is used as one of the alloying components to increase resistance, increase hardness, and reduce the brittleness of steels. Manganese ferroalloys are used to separate excess sulfur and oxygen in steelmaking furnaces, because a high concentration of sulfur in steel reduces its homogeneity and makes it easier to break. Manganese reacts with sulfur and leads to the formation of manganese sulfide in the slag. The main application of manganese in industries is the production of anti-wear manganese alloys and as a vital element for the production of cast iron and steel. Manganese has the most application in the steel production industries, including the production of carbon steels, low-resistance alloys, stainless steels, tools, and wear-resistant steels. This element is also used in the production of non-steel alloys such as non-ferrous alloys, ferroalloys, and cast iron.

Ferromanganese Alloy Production Process

Ferromanganese is produced by heating a mixture of manganese oxide and iron oxide, along with carbon (coal and coke) in an electric arc furnace. In furnaces, the oxides undergo carbothermal reduction operations and are converted to ferromanganese. Ferromanganese is used as a deoxidizing compound for steel. The manganese ore used in this process has 40% manganese, and by adding coke and slag formers such as lime at a temperature of 1200 to 1400 degrees Celsius, the manganese reduction reaction is carried out by coke. In addition to iron and manganese oxide, carbon, phosphorus, and sulfur are also present in this ferroalloy in different ratios.

Related content: Noble and Major Ferroalloys

Buying Ferromanganese Alloy

Supplying ferromanganese in three forms: high-carbon ferromanganese, low-carbon ferromanganese, and medium-carbon ferromanganese in different sizes and with valid analysis and certificates is one of the commercial activities of Avangard Holding. Ferromanganese is available in the form of lumps or powder and in different packages. Please contact the sales experts of Avangard Company to place an order and purchase ferromanganese with your specific or requested analysis.

Ferromanganese Alloy Price

The price of ferromanganese varies based on the analysis and percentage of elements such as manganese, silicon, and carbon in it, as well as its shape and size of the grains. To inquire about the price of various types of ferromanganese, contact Avangard Company.

| Row | Description | Price |

| 1 | Price of High Carbon Ferromanganese | Contact Us |

| 2 | Price of Low Carbon Ferromanganese | Contact Us |

| 3 | Price of Medium Carbon Ferromanganese | Contact Us |

Application of Ferromanganese Alloy

High-carbon ferromanganese is used in the steelmaking industry and the production of various steels due to the outstanding properties it adds to steel. The main applications of this ferroalloy are:

1. Strengthening Mechanical Resistance: Adding ferromanganese to steel increases its compressive and tensile strength. This feature is important in the production of parts that require high strength and resistance.

2. Increasing Hardness: High-carbon ferromanganese adds hardness to steel. This feature is important in cases where parts require a hard and wear-resistant surface, such as tools and machine parts.

3. Reducing Brittleness: Adding this ferroalloy can reduce the brittleness of steel, which is used in some special cases, such as in parts that are exposed to mechanical shocks and vibrations.

4. Production of Tools: This type of steel is used for the production of tools and various types of tools, especially those that require high hardness and resistance.

Related content: Avangard Casting Services

Types of Ferromanganese Alloy

Ferromanganese is divided into three categories: low-carbon ferromanganese, medium-carbon ferromanganese, and high-carbon ferromanganese.

High Carbon Ferromanganese

High-carbon ferromanganese is one of the types of ferroalloys that is used as an important component in the steelmaking industry. High-carbon ferromanganese is known as an alloying element with prominent effects in increasing strength, hardness, and reducing the brittleness of steels. High-carbon ferromanganese is used as a high-carbon ferroalloy for the production of steels that require desirable mechanical properties and resistance to wear and heat. This type of ferroalloy, by increasing the content of carbon and manganese, creates significant effects in increasing the hardness and wear resistance of steel. In general, high-carbon ferromanganese is used as an important additive in the steelmaking industry and brings about effective improvements in the physical and mechanical properties of steels.

Analysis of High Carbon Ferromanganese

| Type of Ferromanganese | % Manganese | % Carbon | % Silicon | % Phosphorus | % Sulfur | % Nitrogen |

| High Carbon Ferromanganese | 76-78 | 6-8 | Max 2 | Max 0.2 | Max 0.05 | Unspecified |

Low Carbon Ferromanganese

Low-carbon ferromanganese is an important ferroalloy in the steelmaking industry that improves the mechanical and physical properties of steel by adding a small amount of manganese to steel with the lowest percentage of carbon. This type of ferromanganese is added to steels as an effective additive and is used in cases where high mechanical strength is required, as well as increased resistance to corrosion and rust.

Related content: Exothermic Sleeves for Risers

Applications of Low-Carbon Ferromanganese:

1. Structural Steels: Low-carbon ferromanganese is used in the production of structural steels that require mechanical strength and corrosion resistance.

2. Automotive Industry: This type of ferroalloy is used in the production of car parts that require hardness, mechanical resistance, and rust resistance.

3. Production of Pipes and Beams: Low-carbon ferromanganese is used in the production of pipes and beams to improve mechanical properties and corrosion resistance.

4. Production of Toothed Tools: In industries that use toothed tools for cutting and drilling, this type of steel is used because of its high hardness and resistance.

5. Production of Machine Parts: In the production of machine parts that require high resistance and hardness, low-carbon ferromanganese is used.

Analysis of Low Carbon Ferromanganese

| Type of Ferromanganese | % Manganese | % Carbon | % Silicon | % Phosphorus | % Sulfur | % Nitrogen |

| Low Carbon Ferromanganese | 83-92 | Max 0.4 | Max 1 | Max 0.03 | Max 0.003 | Unspecified |

Medium Carbon Ferromanganese

Medium-carbon ferromanganese is a type of ferroalloy that is used in the production of steels. This type of ferromanganese is added to steel when a medium amount of carbon is needed, which improves its mechanical and physical characteristics. The average amount of carbon in this ferroalloy usually varies from 0.4% to 2%. This ferroalloy is generally used when the element carbon should be a small amount and it is cost-effective in terms of economic cost.

Analysis of Medium Carbon Ferromanganese

| Type of Ferromanganese | % Manganese | % Carbon | % Silicon | % Phosphorus | % Sulfur | % Nitrogen |

| Medium Carbon Ferromanganese | 75-80 | 0.4-2 | Max 1 | Max 0.2 | Max 0.006 | Unspecified |

فارسی

فارسی  Arabic

Arabic