[rank_math_breadcrumb]

Ferroalloy

Ferroalloy or metal alloys are compounds of iron (Fe) with other elements such as manganese (Mn), aluminum (Al), or silicon (Si), etc. These compounds, due to their grade and structure, are not usable on their own in industries, but by combining them with alloy steels, special properties are created in metals. Ferroalloys are widely used in the production of various metallic and non-metallic alloys. These materials are used in the steel and cast iron industries and casting.

Ferroalloys are alloys that contain iron along with a number of other elements such as aluminum, chromium, manganese, silica, etc. Because the melting point of these elements in their pure state is much higher than when they are alloyed, these elements are very valuable and expensive in their pure form. Due to the high cost and technical problems associated with the preparation of elements in the form of pure metals, their use in pure form is not economically viable, so they are used in the form of ferroalloys. These ferroalloys are used to create different properties in steel and other metals. Usually, these elements are added to molten metals and steel as an alloy.

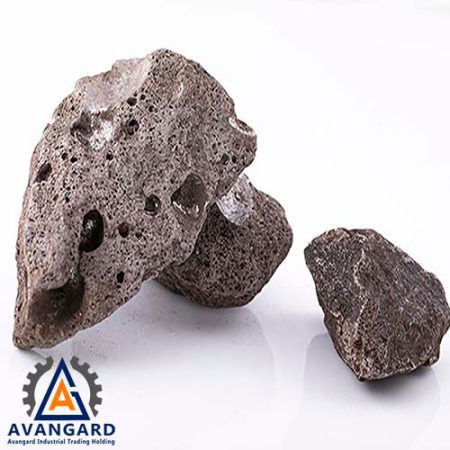

These materials are alloys of iron and other elements such as silicon or manganese that are added to molten metals and steel as alloys and additives. The role of these materials is to create the necessary changes in the final properties of the part by adding the desired alloying elements to the melt. Fluxes are products that are used for melting, igniting, and reducing the melting temperature. These materials may be in the form of minerals, rocks, or synthetic compounds. Fluxes, with a low specific gravity compared to the melt, are concentrated in the upper part of the ladle (or other melting chambers) and are separated from the molten metal as slag. Ferrosilicon, high carbon ferromanganese, low carbon ferromanganese, ferrosilico manganese, ferrochrome and ferromolybdenum are among the most important ferroalloy products in the casting industry.

Types of Ferroalloys

Ferroalloys are materials that include various alloys of iron metal, in which a significant percentage of one or more other elements is present. The use of ferroalloys improves the quality of steel and cast iron materials and products. Ferroalloys are divided into several categories according to the percentage of purity of the target elements and other elements in a compound, or their size and quality.

Ferroalloys are classified into different types according to the desired element, its grade, and its final price. The most important and widely used ferroalloys include the following.

Ferrochrome

Ferrochrome (FeCr) is obtained by combining iron with chromium (Chrome). The main difference between chrome and ferrochrome is the iron present in ferrochrome. The ratio of combined chromium can be in the range of 50 to 70%. Chromium is one of the hardest materials in the world and is not found freely in nature. In addition to these two main alloying elements, various amounts of carbon (C) and other elements such as silicon (Si), sulfur (S), and phosphorus (P) are also present in the composition of this ferroalloy. The raw material for the production of ferrochrome is chromite. The main uses of chromite are in the refractory, metallurgical, and chemical industries.

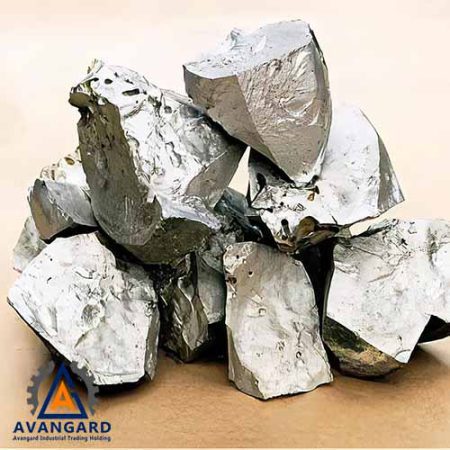

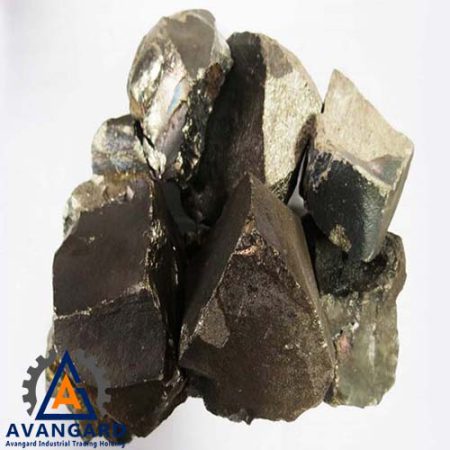

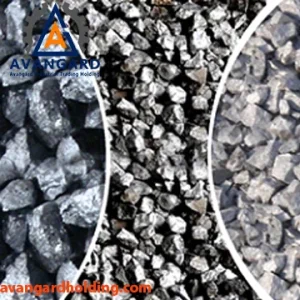

High-carbon ferrochrome is found in solid form and in various forms, including small crystals, granules, lumps, and also as powder particles. The color of this alloy may also vary from dark metallic gray to light gray. Ferrochrome is odorless and insoluble in water. The particles of this ferroalloy are also flammable. The vast majority of ferrochrome production is used for the production of stainless steels. The presence of chromium in the composition of stainless steels makes them resistant to corrosion, and the usual silver color of these steels is due to the presence of chromium.

Ferrochromes are divided into three categories:

1- Low-carbon ferrochrome

2- Medium-carbon ferrochrome

3- High-carbon ferrochrome.

The classification of Fe-Cr ferrochrome is generally based on the ratio of chromium to carbon in the alloy. It should be noted that another type of ferrochrome called nitrogen-containing ferrochrome is produced, which is generally used in duplex steel melts that require the presence of nitrogen along with chromium.

Ferromanganese

Ferromanganese is a ferroalloy with a high amount of manganese; high carbon ferromanganese may contain 70-80% manganese by weight. Manganese, if used as a mineral rock or as a ferroalloy, is used in the steel industry. One of the major roles of manganese, including ferromanganese, is as a reducing and cleaning agent in molten steel, which is used to remove sulfur and improve the properties of steel. This ferromanganese acts as a reducing element, absorbs sulfur and interfering elements, and introduces them into the slag. Ferromanganese is in solid form and its shape is like a lump. This ferroalloy is odorless as long as it is dry. Usually, these ferromanganese are supplied in sieved and crushed form.

The ferromanganese ferroalloy is divided into three parts: high-carbon ferromanganese, low-carbon ferromanganese, and medium-carbon ferromanganese. This is because after using ferromanganese, its carbon content cannot be increased or decreased, and this alloy contains combinations of iron, carbon, manganese, sulfur, and phosphorus. In the high-carbon state of ferromanganese, the carbon percentage reaches 8%. Manganese ferroalloys are used to separate sulfur and excess oxygen in steelmaking furnaces. This is important because a high concentration of sulfur in steel can reduce its homogeneity and make it easier to break. For this reason, manganese combines with sulfur to form manganese sulfide in the slag, thereby helping to purify the steel.

Related content: Graphite

Noble and Major Ferroalloys

Noble and major ferroalloys refer to a combination of iron with other specific elements. These alloys usually include iron along with one or more other elements such as titanium, tungsten, niobium, vanadium, molybdenum, and boron. The term "noble ferroalloy" refers to alloys that include precious and valuable metals. Due to the unique properties of these precious metals, noble alloys are of great value. The use of these metals in alloy compositions as a noble ferroalloy usually helps to produce high-quality and valuable products.

Major ferroalloy refers to the combination of iron with elements such as silicon, chromium, manganese, phosphorus, and magnesium, etc. These ferroalloys have a greater consumption in the industry than noble ferroalloys. These ferroalloys increase the mechanical and physical properties of metals and ultimately improve the quality of production of parts and casting efficiency. It should be noted that ferromanganese and ferrochrome, which were previously explained, are subsets of this category, which are themselves divided into several types.

Application of Ferroalloys

The most important applications of ferroalloys in the industry include the following

1. Deoxidation

Deoxidation during steelmaking is one of the most important types of applications of ferroalloys. Ferroalloys are used to produce steel as an oxygen absorber. In steelmaking, raw iron must undergo an oxidation process. During this operation, unwanted materials and impurities of iron such as phosphorus, sulfur, carbon, etc. are converted into oxides by oxygen and placed inside the slag. To increase the quality of iron and prevent the formation of pores and holes (resulting from residual oxygen in the melt) in the final parts, deoxidation must be performed before the end of processing.

The best way to deoxidize is to add a ferroalloy that contains elements that have a greater tendency to combine with oxygen than iron itself. The optimal elements for the deoxidation process include aluminum, chromium, silicon, and manganese.

2. Inoculation in Casting

The use of ferroalloys in inoculation during the solidification of molten metals can help improve the solidification process and the final properties of the metal. Molten metals may naturally turn into nuclei called "dendrites" during solidification, which may have undesirable mechanical and structural properties. The use of ferroalloys can help in controlling these nuclei and improving the properties of the final materials. Some ferroalloys may create more optimal solidification and structural properties and prevent the formation of undesirable nuclei. This action can help control the grain size and uniformity of the structure in solidified metals and ultimately improve the mechanical and structural properties of the metal.

Related content: Raw materials for casting

3. Alloying

Some of the applications of ferroalloys in this field include the following:

Control of nucleation and grain structure:

Ferroalloys can be used as a controlling agent to prevent unwanted nucleation and control the grain structure of molten metals.

Control of heterogeneous solidification:

These alloys can help control the heterogeneous solidification of alloys and reduce the occurrence of structural defects.

Reduction of metal density:

By adding ferroalloys, the density and specific gravity of metals can be changed, which is required in some cases.

Changes in mechanical properties:

These alloys can change the mechanical properties of metals and improve resistance, strength, and other mechanical properties.

All these applications are aimed at improving and controlling the processes of solidification and cooling of molten metals.

Method of Producing Ferroalloys

For the production of ferroalloys, materials such as non-ferrous mineral rocks, coal coke, and iron ore are used. In the past, blast furnaces were used for this production, but currently, electric arc furnaces are used. However, some ferroalloys such as ferromanganese are still produced using traditional methods.

In electric arc furnaces, ferroalloys are produced by performing carbothermic reactions. In these reactions, the oxides present in the raw materials are reduced with the presence of iron and by carbon and carbon monoxide formed from coke, and ferroalloys are formed. For the production of some ferroalloys, the desired elements are added to molten iron and the production process of the desired ferroalloy is carried out.

Related content: Refractory coatings for casting

Price of Ferroalloys

Ferroalloys are produced by combining a base metal with one or two other metals with different purity percentages. Ferroalloys have different types that have different purity percentages of elements. The price of casting ferroalloys varies depending on the purity percentage and the weight percentage of the elements used in them. Among the factors affecting the production of ferroalloys, one can often mention whether they are domestic or imported. Another factor influencing the price is the brand of the ferroalloy manufacturer, in such a way that ferroalloys produced by well-known brands often have a higher price than ordinary brands. Avangard Company is one of the reputable companies active in the field of purchasing ferroalloys, and you can visit the company's website to inquire about the price of ferroalloys and obtain more information in this regard. You can also contact the company's ferroalloy sales experts through the existing communication channels to get expert advice on purchasing ferroalloys, placing orders, and inquiring about the price of various types of ferroalloys.

Purchase of Various Ferroalloys from Avangard Holding

Online shopping has become very popular in today's world, and many online stores around the world are trying to enable people to purchase their needs in the shortest time and in the best way. Avangard Holding online store is the most comprehensive store where you can purchase any type of ferroalloy and inoculant at the cheapest available price and the highest possible quality, as well as the additives you need. All types of ferroalloys are available in Avangard Holding, and by visiting the page of these products, you can choose the best option. Specifications, images, and prices of all ferroalloy products are available in Avangard Holding. Avangard Holding has various smart filters that make the selection process easier. For example, if you need a noble ferroalloy, you can see other related sleeves in the similar products section and complete your purchase.

فارسی

فارسی  Arabic

Arabic