[rank_math_breadcrumb]

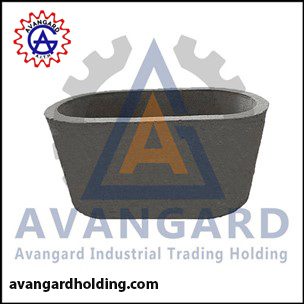

Oval Sleeve

The use of oval exothermic insulation sleeves or prefabricated feeders in the steel and cast iron industries is an important method for increasing the quality and precision of parts. This process, by creating a feeding system through an oval sleeve, which is a prefabricated chamber, allows the creation of a suitable thermal gradient for the directional solidification of the part. This process improves the quality and soundness of the parts.

Choosing the best type of sleeve for each casting is different, depending on the shape and weight of the part, after feeding calculations based on the modulus of the part and the modulus of the feeder. The use of oval feeding sleeves can improve the performance of cast parts and makes it possible to reduce costs and eliminate shrinkage defects. Oval sleeves are often used in ring and gear parts to increase the feeding range and reduce the number of feeders, which increases casting efficiency. In summary, the use of oval exothermic sleeves plays a very important role in improving the quality of the part and ensuring its soundness, and with careful calculations and their use, desired results can be achieved in the casting process.

Types of Oval Exothermic Sleeves

The use of oval exothermic sleeves in the casting process can help reduce costs and optimize process performance. Increasing the range of melt delivery by the sleeves leads to a reduction in production time and costs in casting. By correctly selecting the type and size of the feeder, it facilitates the creation of a suitable thermal gradient from the feeder to the cast part. As a result, the use of oval feeding sleeves can also reduce the costs associated with the finishing section and post-casting processes.

Related article: Cylindrical Sleeve

Technical Features of Oval Exothermic Sleeves

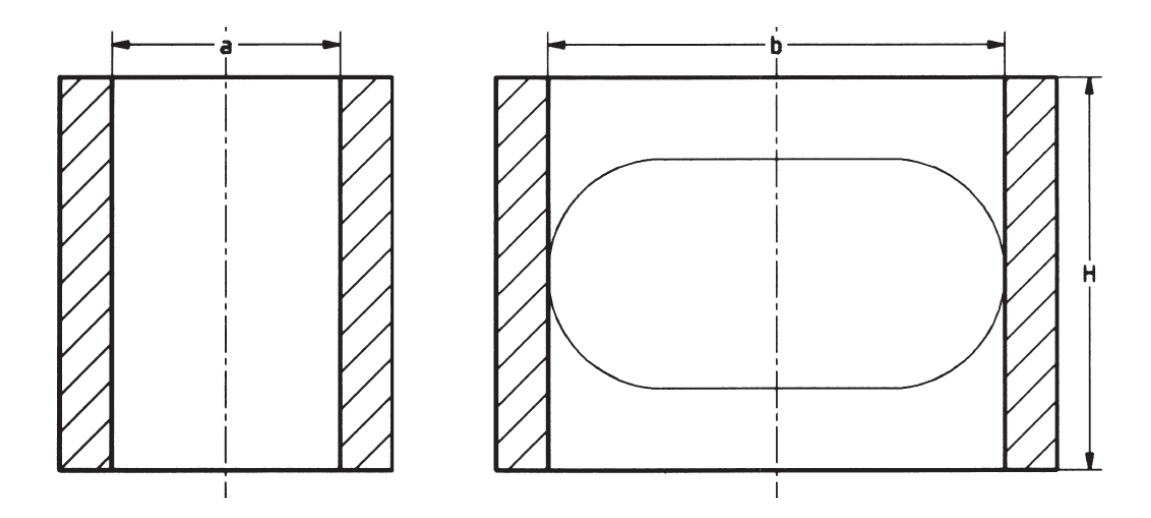

1. Dimensions and Size:

The dimensions of oval sleeves vary depending on the modulus of the cast parts. These dimensions include the major diameter, minor diameter, height, as well as the amount of melt delivery range and the diameter of the feeding area.

2. Feeding Capacity:

This specification indicates the volume of molten metal in the feeder, which the sleeve is able to hold for supplying molten metal to the cast parts.

Technical specifications of oval exothermic sleeves

When the melt enters the sleeve chamber, chemical reactions begin and a lot of heat is released. The remaining materials in the sleeve, after the reaction is complete, act as an exothermic thermal insulator and keep the heat concentrated in the feeder. This feature creates a suitable thermal gradient for directional solidification for a long time and prevents non-homogeneous deviations in the structure of the part.

Oval exothermic sleeves are available in sizes of O4, O5, O6, O7, O8, O9, O10, O11, O12, and O13 in Avangard Company.

| SIZE | MG | COEFFICIENT | ME | A | B | H | W (Kg) |

| O4 | 1.72 | 1.45 | 2.49 | 62 | 147 | 140 | 8.3 |

| O5 | 2.08 | 1.45 | 3.02 | 84 | 162 | 150 | 13 |

| O6 | 2.54 | 1.45 | 3.68 | 98 | 200 | 195 | 24.5 |

| O7 | 2.94 | 1.45 | 4.26 | 120 | 240 | 200 | 37 |

| O8 | 3.28 | 1.45 | 4.75 | 140 | 282 | 200 | 51 |

| O9 | 3.52 | 1.45 | 5.10 | 154 | 323 | 200 | 64 |

| O10 | 3.82 | 1.45 | 5.54 | 176 | 364 | 200 | 83 |

| O11 | 4.12 | 1.45 | 5.97 | 202 | 403 | 200 | 105 |

| O12 | 4.42 | 1.45 | 6.40 | 227 | 458 | 200 | 134 |

| O13 | 4.57 | 1.45 | 6.62 | 238 | 502 | 200 | 155 |

Related article: Potted Sleeve

Application of Oval Exothermic Sleeves

Oval exothermic sleeves are used in the casting industry as a basic element in the feeding system. The key purpose of using oval sleeves is to improve the feeding process in casting and reduce costs. Oval feeding sleeves are mainly used in circular parts such as various rings and gears to reduce the number of feeders and also to increase the feeding range, which in total increases the efficiency of casting. Some applications of oval feeding sleeves include:

1. Improved Feeding Performance: Oval exothermic sleeves increase the range of melt delivery and make it possible for the melt feeding process of parts to be done in the best way.

2. Cost Reduction: Increasing productivity in the casting process leads to a reduction in costs. The use of oval exothermic sleeves can be effective in this direction.

3. Elimination of Shrinkage Defects: Sleeves, by creating a suitable thermal gradient from the feeder to the cast part, help to eliminate undesirable shrinkages.

4. Improving the Quality of Cast Parts: The use of oval sleeves improves the quality of cast parts.

5. Reduced Production Time: By increasing the range of melt delivery and improving feeding, production time can also be reduced.

Price of Oval Exothermic Sleeves

Oval sleeves are available in Avangard Holding according to different advantages and specifications, and their price varies according to quality, size, and technical specifications. For more information and to inquire about the price of oval exothermic sleeves, please contact the sales experts at Avangard Holding.

| Row | Price | Description | Price |

| 1 | Contact us | Price of Oval Sleeve O4 | Contact us |

| 2 | Contact us | Price of Oval Sleeve O5 | Contact us |

| 3 | Contact us | Price of Oval Sleeve O6 | Contact us |

| 4 | Contact us | Price of Oval Sleeve O7 | Contact us |

| 5 | Contact us | Price of Oval Sleeve O8 | Contact us |

| 6 | Contact us | Price of Oval Sleeve O9 | Contact us |

| 7 | Contact us | Price of Oval Sleeve O10 | Contact us |

| 8 | Contact us | Price of Oval Sleeve O11 | Contact us |

| 9 | Contact us | Price of Oval Sleeve O12 | Contact us |

| 10 | Contact us | Price of Oval Sleeve O13 | Contact us |

Related article: Ferroalloy

Sale of Oval Exothermic Sleeves

The price of oval exothermic sleeves varies according to their thermal capacity, dimensions, suitable feeding range, effective modulus of the feed, or the type of order requested by the customer. To produce, order, and purchase various types of oval feeding sleeves, contact the sales experts at Avangard Holding.

فارسی

فارسی  Arabic

Arabic