[rank_math_breadcrumb]

Cylindrical Exothermic Sleeve

The cylindrical exothermic insulating sleeve is used as a vital tool in the casting process. This insulating sleeve is responsible for supplying and feeding the solidifying cast parts. By delaying solidification, it improves the quality and efficiency of the cast parts. Cylindrical feeding sleeves, by allocating a volume of molten feed, can provide molten metal in a certain proportion to the volume of the cast part at the end of the casting process and delay the solidification process to prevent the formation of metallurgical defects in the part.

By using these tools, the performance of cast parts is improved, and it also becomes possible to reduce costs and eliminate shrinkage defects. It is recommended that, in calculations, a maximum of 33% of the molten feed volume be considered for feeding the parts to ensure that the remaining feed modulus is sufficiently supplied to the cast part at the end of the process.

In short, cylindrical exothermic sleeves play a very important role in improving the quality and efficiency of cast parts, and by paying attention to calculations and using them, desired results can be achieved in the casting process. To purchase all types of cylindrical exothermic sleeves, contact the sales experts at Avangard Holding.

Technical Specifications of Cylindrical Exothermic Sleeves

The technical specifications of cylindrical feeding sleeves are usually related to various factors, including dimensions, feeding capacity, material type, properties of the construction materials, and their technical capabilities. This sleeve is not recommended for light and non-ferrous alloys.

The use of cylindrical feeding sleeves in the casting process can greatly help improve performance and reduce costs. These tools, by increasing casting efficiency, by improving the molten metal feeding process, reduce melt consumption, and as a result, save material consumption. On the other hand, increasing the range of molten metal delivery by the sleeves leads to a reduction in production time and costs. By correctly selecting the type and size of the feeder, they provide a suitable thermal gradient from the feeder towards the cast part, which can help reduce the required force for production and eliminate problems caused by uneven heat in parts. As a result, by using cylindrical feeding sleeves, the costs associated with the finishing section and the processes after casting can also be reduced.

Related Article: Avangard Casting Services

Here are some of the key technical specifications of cylindrical feeding sleeves:

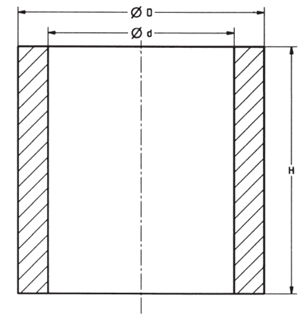

1. Dimensions and Measurement: The dimensions of cylindrical sleeves can be variable and may differ depending on the needs and dimensions of the cast parts. These dimensions may include the diameter and height of the cylinder, as well as the diameter and range of molten metal feeding in the feeding area.

2. Feeding Capacity: This feature indicates the volume of molten metal feed that the sleeve is capable of holding and supplying to the cast parts.

Related Article: Pot Sleeves

Technical Specifications of Cylindrical Sleeves

| Row | Sleeve Size | H (mm) | d (mm) | Effective Modulus (Cm) | Molten Metal Weight (Kg) |

| 1 | 100*100 | 100 | 100 | 2.5 | 6.1 |

| 2 | 100*150 | 150 | 100 | 2.81 | 9.2 |

| 3 | 125*150 | 150 | 125 | 3.31 | 14.4 |

| 4 | 150*150 | 150 | 150 | 3.75 | 20.7 |

| 5 | 150*200 | 200 | 150 | 4.1 | 27.5 |

| 6 | 185*200 | 200 | 185 | 4.58 | 42 |

| 7 | 200*200 | 200 | 200 | 4.8 | 49 |

| 8 | 225*200 | 200 | 225 | 5.22 | 61.2 |

| 9 | 275*200 | 200 | 275 | 5.9 | 93 |

| 10 | 350*200 | 200 | 350 | 6.58 | 150 |

| 11 | 275*300 | 300 | 275 | 6.83 | 139 |

| 12 | 400*200 | 200 | 400 | 7 | 196 |

Related Article: Oval Sleeves

Types of Dimensions of Cylindrical Exothermic Sleeves

To determine the correct size of the sleeve, the modulus and solidification shrinkage are effective. From the table given above, you can choose the feed with the desired modulus, volume, and dimensions. Prefabricated cylindrical sleeves are designed in different diameters and heights, according to the needs, to create a suitable thermal gradient from the feed to the part, and to create a suitable molten metal delivery range. Cylindrical sleeves are available in sizes of 100*100, 150*100, 150*125, 150*150, 200*150, 200*185, 200*200, 200*225, 200*275, 200*350, 200*400, 300*275.

Price of Cylindrical Sleeves

Different cylindrical feeding sleeves with different features and specifications are available in the market, and their price also varies depending on the size, quality, and technical specifications. Please contact us at Avangard Holding to inquire about the price of various types of cylindrical sleeves.

| Row | Description | Price |

| 1 | Price of Cylindrical Sleeve 100*100 | Contact us |

| 2 | Price of Cylindrical Sleeve 150*100 | Contact us |

| 3 | Price of Cylindrical Sleeve 150*125 | Contact us |

| 4 | Price of Cylindrical Sleeve 150*150 | Contact us |

| 5 | Price of Cylindrical Sleeve 200*150 | Contact us |

| 6 | Price of Cylindrical Sleeve 200*185 | Contact us |

| 7 | Price of Cylindrical Sleeve 200*200 | Contact us |

| 8 | Price of Cylindrical Sleeve 200*225 | Contact us |

| 9 | Price of Cylindrical Sleeve 200*275 | Contact us |

| 10 | Price of Cylindrical Sleeve 200*350 | Contact us |

| 11 | Price of Cylindrical Sleeve 200*400 | Contact us |

| 12 | Price of Cylindrical Sleeve 300*275 | Contact us |

Related Article: Ferromanganese

Purchase of Cylindrical Sleeves

Cylindrical sleeves vary in price depending on their size and thermal capacity, modulus, range of molten metal delivery, or the model requested by the customer and price fluctuations. To purchase, produce, and order various types of cylindrical sleeves, contact the sales experts at Avangard Holding.

فارسی

فارسی  Arabic

Arabic