[rank_math_breadcrumb]

What is an Exothermic Sleeve?

Feeding in casting is used to compensate for the volume changes of the metal in the liquid state and during solidification. The purpose of feeding is to prevent shrinkage defects and to maintain directional solidification in the production of cast parts.

If, for any reason, directional solidification does not occur from the part towards the feeder, no type of feeding will be effective in preventing shrinkage cavities in that part.

To make the solidification directional, the part must cool at a higher rate than the feeder. In this regard, heat-generating and heat-insulating materials that are placed around the feeder are used in some parts instead of refrigerating the part to increase the cooling rate of the part and create directional solidification. These types of feeders are known as exothermic sleeves. By maintaining the heat of the feeder, the cooling rate is reduced, and by creating a thermal gradient in the mold, directional solidification occurs from the part towards the feeder. By using a sleeve feeder, its volume is reduced, and production efficiency is increased.

Avangard Company produces various types of exothermic insulating sleeves, including pot-shaped or conical sleeves, oval sleeves, and cylindrical sleeves. To inquire about the purchase price, order, and receive technical specifications, please contact the sales unit of raw materials for casting.

How Exothermic Sleeves Work

Exothermic sleeves are prefabricated feeders that are heat-insulating and, by delaying the solidification process, lead to increased efficiency compared to conventional sand and termite feeders. The use of these auxiliary feeders improves the efficiency of casting parts, reduces cleaning costs, eliminates shrinkage defects, and more.

The special method of production and the use of very lightweight refractory materials enable these sleeves to be produced with a low density of about 0.6 g/cm³, and also enables their exothermic reaction, which occurs at temperatures up to 1620 °C.

Sleeve feeders can supply about 33% of the feed volume to the solidifying cast part, but it is recommended that 30% of the molten feed volume be considered for feeding the part for calculating the amount of molten metal needed during solidification.

To select the correct sleeve size, it is suggested that both the modulus and the solidification shrinkage be considered. It should be noted that the use of these sleeves is not recommended for light and non-ferrous alloys.

Types of Exothermic Sleeves

Prefabricated sleeves can be classified into different types in terms of geometric shapes and how they work, which are mentioned below:

a) Types of Exothermic Sleeves in Terms of Geometric Shapes

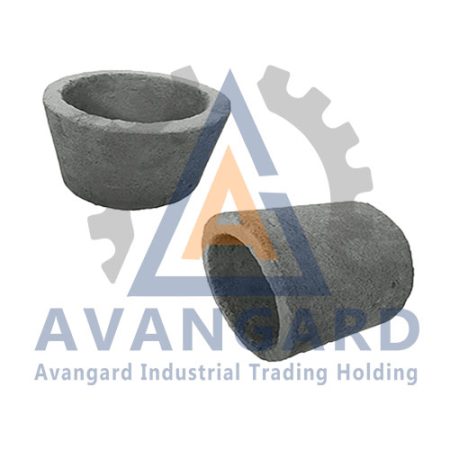

- Cylindrical sleeve

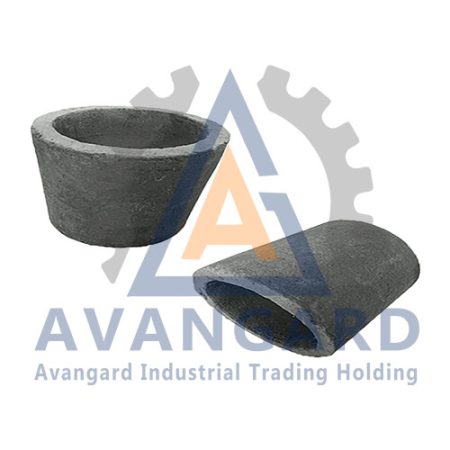

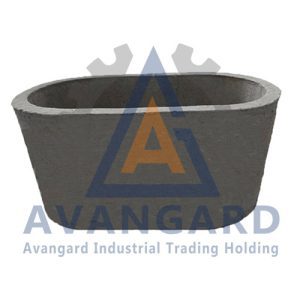

- Oval or bean-shaped sleeve

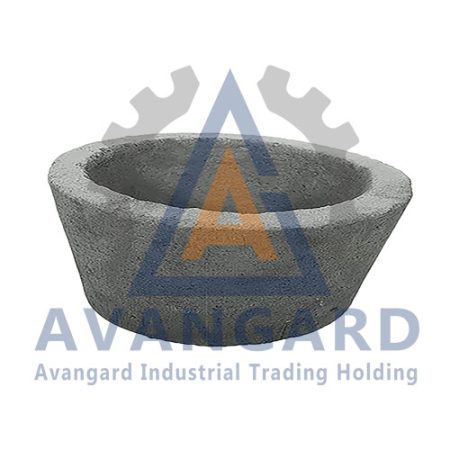

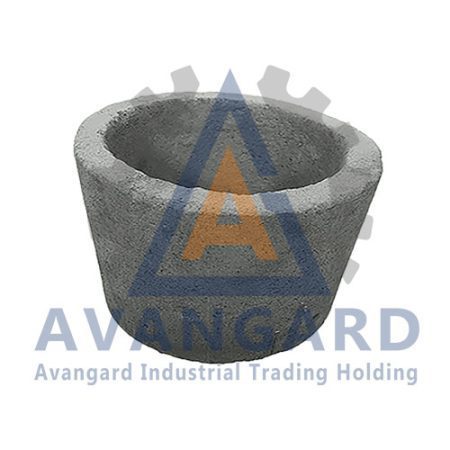

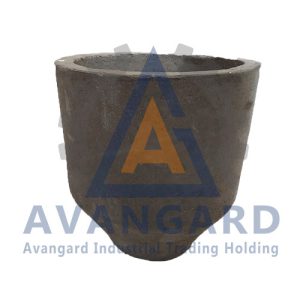

- Pot-shaped or conical sleeve or conic sleeve

- Blind sleeve

- Louvered pad sleeve

b) Types of Exothermic Sleeves in Terms of Performance

- Insulating sleeve

- Large size insulating exothermic sleeve

- Small size insulating exothermic sleeve

You, esteemed casters, can contact the sales experts or visit the sales page of the exothermic insulating sleeves mentioned in the types of pot-shaped or conical exothermic sleeves, oval exothermic sleeves, and cylindrical exothermic sleeves to purchase them at a reasonable price and with high quality and efficiency. You can also visit the sales pages for , graphite, pure metals, and refractory casting coatings.

Cylindrical Exothermic Sleeve

Cylindrical feeder: It is used for parts that need to have a uniform feeding range distribution radially around the feeder to prevent shrinkage and casting defects.

Oval or Bean-Shaped Exothermic Sleeve

Oval feeder: It is used for parts with a shape similar to round rings or gears or parts with a long length that only require feed range in the longitudinal part of the feeder, which saves the number of feeders by increasing the feeding range and increases the efficiency of casting the part and prevents shrinkage and casting defects around the part.

Pot-Shaped or Conical Exothermic Sleeve

Pot-shaped or conical feeder: It is used for parts where the feed range is important radially around its perimeter, and also when separating the feeder from the part is difficult due to the type of melt, for example, in high-chromium or nihard melts. A conical feeder is used because the conical shape of the bottom of the part and the presence of a notch at the neck of the feeder makes it easy to separate the feeder from the part, which reduces costs in the finishing section and reduces the possibility of various casting defects.

Advantages of Using Sleeve Feeders in Cast Parts

- Increased efficiency of parts in casting

- Savings in molten metal consumption

- Increased molten metal delivery range in production technology

- Reduction of casting production costs

- Creating a suitable thermal gradient from the part to the feeder due to the presence of special materials in the production of the sleeve

- Reduction of costs in the finishing section of cast parts

Storage of Exothermic Sleeves:

Due to the sensitivity of sleeve feeders to humid environments, they should be stored in a dry place.

Price of Exothermic Sleeves

At Avangard Holding Company, the price of thermal insulating exothermic sleeve feeders (Foundry Riser Sleeve) varies depending on the dimensions and type of materials used. To get an accurate price and more information, you can contact the sales unit of Avangard Company and get advice. We will help you choose the best feeder with the most suitable price and the highest quality efficiency for your casting needs and make your purchase.

Price List of Thermal Insulating Exothermic Sleeves

| Row | Description | Price |

| 1 | Price of Cylindrical Exothermic Sleeve | Contact us |

| 2 | Price of Pot-Shaped or Conical Exothermic Sleeve | Contact us |

| 3 | Price of Oval or Bean-Shaped Exothermic Sleeve | Contact us |

Sale of Exothermic Sleeves

Relying on two decades of experience and the knowledge of expert metallurgy engineers in the field of design and technology of cast parts, Avangard Holding is proud to offer thermal insulating exothermic sleeve feeders. The sales experts of Avangard are fully prepared to provide you with consulting services and the necessary information to choose the best sleeve feeder for your needs. You can contact the sales unit of Avangard Company to purchase your products and benefit from the professional experience and superior quality of this company.

فارسی

فارسی  Arabic

Arabic