[rank_math_breadcrumb]

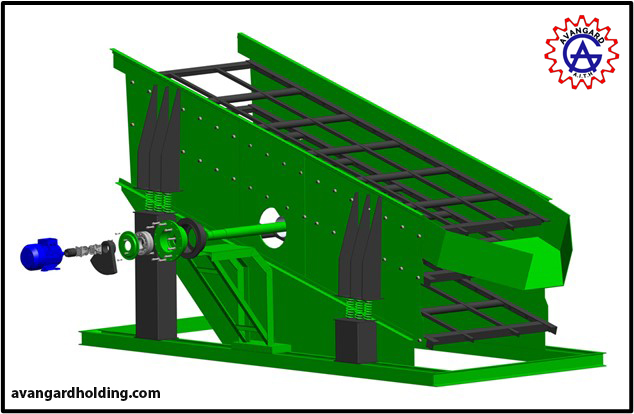

Screening Machine

The screening machine is used for separating and sorting materials and stones from each other. Typically, different types of crusher screens are manufactured in various lengths, widths, and layers to optimize the use of the effective surface of the screen mesh, enabling them to grade materials and screen in capacities calculated in tons per hour. The meshes of various screening machines, particularly vibrating screens, come in different types. For example, iron mesh screens or steel mesh screens can be mentioned. Another type of mesh is the thick screen mesh which is produced in different dimensions.

Purchase Screening Machine from Avangard Holding

Online buying and selling is very established in today’s world, and many online stores around the world strive for people to meet their needs in the shortest time and in the best way. The Avangard Holding online shop is the most comprehensive store where you can buy any type of parts, devices, and other necessary items. Various types of screening machines are available at Avangard Holding, and by visiting the product pages, you can select and purchase your desired product with a reasonable price and high quality.

Screening Machine Price

The price of the sand washer screening machine varies based on the type and capacity of the machine or the specific type desired by the customer and price fluctuations. For ordering, purchasing, and manufacturing your desired screening machine, contact the sales experts at Avangard Company.

Types of Screening Machines

The crusher screening machine is one of the equipment used in mining extraction and mineral processing industries. This machine is used as part of the sand and gravel mining equipment, responsible for separating crushed mineral materials with different dimensions. Generally, screens for crushers are made of steel and have grids with different dimensions which allow crushed materials to be separated by size. Materials smaller than the grid size pass underneath, and larger materials remain on the screen and are discharged from there.

By using the crusher screen mesh, mineral materials can be separated based on the desired size for further processing stages. This process is very important for controlling the dimensions and sizes of mineral materials to increase the efficiency of processing and mining extraction. Types of screens include vibrating screens, revolving screens, grizzly screens, flat screens, and inclined screens available in one-layer, two-layer, and three-layer models.

Related content: Crusher Machine

Vibrating Screening Machine

The vibrating or oscillating screen machine is a device used for separating materials and stones from each other. It is considered one of the commonly used devices in various industries.

The vibrating screen usually consists of a series of horizontally placed steel frames holding the screen plates. In a vibrating screen, the vibration causes horizontal and vertical movements in the particles of stones and materials present on the screen. These oscillating movements cause the separation and sorting of materials with different sizes and characteristics, which is very important in various industry processes such as mining, construction, and material processing.

Rotary Screening Machine

The rotary or cylindrical screen machine is an old type of screen that is cylindrical in shape and is installed horizontally with a slight slope. This machine rotates around its axis. The input materials enter from one side of the cylinder and are distributed on its surface due to the slope and rotation of the screen, flowing towards the other end of the cylinder. Particles smaller than the screen holes pass through, and larger particles exit from the other end of the cylinder. Rotary screens are generally used for separating materials in wet or dry conditions.

Related content: Conveyor Belt

Grizzly Screening Machine

The grizzly screen is a type of stationary, immobile screen where materials flow on its surface due to the slope. The screen surface is made of parallel rods spaced at determined intervals. The rod sections in different grizzlies vary, and it is better for the trapezoidal section of the rods to be larger at the top to reduce the likelihood of material getting stuck in them. Grizzly rods should be made of wear-resistant alloys such as manganese steel. In some types of grizzlies, chains are used instead of rods. Grizzly rods are usually installed with a slope of about 20 to 50 degrees. The higher the slope, the higher the passing speed, thus increasing the capacity of the grizzly screen, but efficiency decreases. The direction of the initial load material on the grizzly is parallel to the rods, making material movement easier and reducing the chance of them getting stuck between rods.

Related content: Sand Washer

Technical Specifications of Screening Machine

The technical specifications for constructing an industrial screen can include the following:

1. Physical dimensions: Height, width, length, and overall dimensions of the machine.

2. Capacity: The screen's ability to process and separate materials per unit time, usually measured in tons or tons per hour.

3. Measurement range: The minimum and maximum size of particles or materials that the screen can process.

4. Type of materials that can be processed: The specifications of materials and mineral, chemical, or other materials that can be separated by the screen.

5. Motor power: The power of the motor or motion system that can drive the screen.

6. Construction materials: The material and structural components of the screen, such as stainless steel, aluminum, or wear-resistant materials.

7. Type of motion: Fixed or rotary, the motion state of the screen, and the method of material separation.

8. Type of screen: Whether it is a grizzly or vibrating screen and other types of screens.

9. Control system: Level of control and monitoring over the separation process and device performance.

10. Adjustment capability: The ability to adjust slope, speed, and other parameters related to screen performance.

These specifications can vary depending on the type and application of the screen machine and may include additional specifications for each screen type.

Related content: Feeder Machine

Applications of Screening Machine

The screening machine is a versatile tool in various industries and has a wide range of applications. Below are some of the main applications of this device:

1. Mineral purification: In mining and extraction industries, screens are used to separate and purify various minerals. This includes separating various mineral rocks, such as coal, iron ore, copper, stones, sand and gravel, ores, etc.

2. Construction industries: In construction industries, screens are used for separating construction materials such as sand, gravel, iron ore, and building stones.

3. Drilling industries: In drilling industries, this device is used to separate drilling coals and other particles from drilling materials.

4. Construction-related industries: In construction projects and civil engineering facilities, screens are used to separate mineral and non-mineral materials.

5. Other industrial applications: In some other industries, such as oil and gas, agriculture, and water purification processes, food and chemical and pharmaceutical industries, screens are used for separation and purification of materials.

فارسی

فارسی  Arabic

Arabic