[rank_math_breadcrumb]

Sand Washer

In washing equipment for materials and aggregates, which includes the sand washer, this device is used in the crusher production line and mineral crushing for separating and removing mud and extra materials. It is usually installed below the first screen. The sand washing process removes fine particles and other very small materials via high-speed water, separating them from other rocks, and then expelling them from the main load. As a result of this process, fully washed and cleaned sand is produced. The type of sand washing machine is very crucial in sand and gravel mining as it leads to more robust and durable construction materials and concrete and asphalt by properly washing and removing extraneous materials.

Sand Washer Sales

Avangard Company, specializing in the production and sale of crusher sand washers, offers efficient tools for washing and screening sand. These devices are known for their high quality, excellent efficiency, and reliability, facilitating and enhancing the production and manufacturing processes of construction and road-building materials.

Sand Washer Price

Usually, the price of crusher sand washers varies depending on size, efficiency, and technical features. For more accurate pricing information, it is best to contact Avangard experts and study the price according to your needs.

| No. | Description | Price |

| 1 | Price of Single Spiral Sand Washer | Contact Us |

| 2 | Price of Double Spiral Sand Washer | Contact Us |

| 3 | Price of Scrubber or Mixer Sand Washer | Contact Us |

| 4 | Price of Double Bucket Wheel Sand Washer | Contact Us |

| 5 | Price of Thickener Machine (Thickener) | Contact Us |

| 6 | Price of EvoWash Sand Washing Plant | Contact Us |

Online Purchase of Crusher Sand Washer

If you are looking to buy and sell crusher sand washers online from anywhere in the country and intend to purchase the best, highest-quality, and most reasonably priced sand washer machine, Avangard Holding provides you with various types of sand washers. You can visit the Avangard Holding website, choose your desired products online, and then receive them in the shortest time possible.

Related Content: Screen Machine

What is a Sand Washer?

The sand washer is an essential piece of equipment in the crusher industry used for washing and purifying extracted sands in mining and construction industries. These sand washers use various processes such as washing, screening, and separation to cleanse raw sands from contaminated and undesirable particles. Types of sand washer machines include single spiral, double spiral, scrubber, dual-axis bucket wheel sand washers, and more modern types like EvoWash and thickeners. Each type of machine has specific features and applications depending on environmental needs and conditions. These devices improve the quality and standards of sand output from mines and are used in production and construction of buildings and other structures. A hydrosander or combined type, known as the Hydrocyclone Sand Washer, is also produced and highly popular in this field. For price inquiries, ordering, technical specifications, and catalog receipt, please contact Avangard's technical consultation unit.

Types of Sand Washers

Types of sand washers include single spiral, double spiral, scrubber or mixer, dual-axis bucket wheel, EvoWash, thickeners, and more. Each of these machines is used for purifying and washing mineral sands with specific features and applications. We will briefly explain each type below, so stay with us.

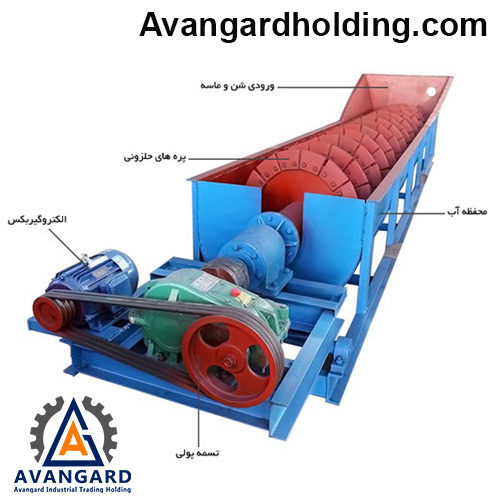

Single Spiral Sand Washer (Screw Sand Washing Machine)

The single spiral sand washer, also known as the spiral classifier, is one of the mineral equipment in the crusher industry used for separating and washing raw sands. This device uses a spiral to move the sands within a tank. During the movement, sands are arranged by gravity and water flow to a specific size, separating them from contaminated particles. In this process, heavier particles are separated towards the lower part of the spiral due to gravity, while lighter particles are moved towards the top of the spiral with the water flow and are dismissed there.

The single spiral sand washer is recognized as one of the first and simplest sand-washing devices. This machine is typically placed alongside other mining equipment like screens and crushers and is used in various mining extraction projects. The advantages of this machine include simple operation, lower costs compared to more advanced devices, and usability in different environmental conditions.

Double Spiral Sand Washer (Double Spiral Sand Washer)

The double spiral sand washer is one of the sand and gravel mining equipment used for washing and separating raw sands. This device features two parallel spirals located within a tank. Raw sands and incoming water are moved by the spirals. In this process, the sands are arranged by gravity and water flow to specific sizes, separating them from contaminated and impure particles.

With two parallel spirals, the performance and efficiency of the double spiral sand washer are enhanced. This device is commonly used for materials with medium to large concentrations and particles. Additionally, having two spirals increases the ability to process sand on a larger scale and more rapidly. Furthermore, this machine demonstrates high efficiency in removing fine and mineral impurities, improving the quality of the output sand.

Sand Scrubber Mixer

The sand scrubber or mixer utilizes flow and friction to remove contaminated particles from the surface of sand and gravel, aiding in cleaning and improving the quality of the sand and gravel for better materials used in various industries. The sand scrubber or mixer is commonly used in mining, building materials production, rock aggregate preparation, construction equipment, and related industries.

The use of scrubbers or mixers is extremely useful for cleaning and purifying raw materials and materials that are adhered to mud. This device provides improved material quality and impurity removal by regulating water pressure and flow, resulting in better and more suitable materials for various industries.

Related Content: Feeder Machine

Bucket Wheel Sand Washing Machine

The double-axis bucket wheel sand washer (Bucket wheel classifier) is another type of sand washer used in sand and gravel mines, designed for larger tonnages and higher capacities. This type of sand washer is primarily used for cleaning lucht sand. In the machine, a rotating wheel with bucket-like sections is used in place of spiral blades, thus called the bucket wheel sand washer. The rotating wheel and water basin in this model are larger, causing slower sand movement and lower turbulence. This device features three water outlets and two inlets for greater water savings compared to spiral sand washers.

The capacity of the bucket wheel sand washer is approximately 80 tons per hour and is used in large production lines. The slow wheel speed and high basin height with water outlets lead to water savings and decreased moisture in sand and gravel. By using this mechanism, more mud is settled, enhancing the quality of the output sand. Due to these features, this sand washer model has a higher price than the spiral sand washer.

EvoWash Sand Washing Plant

Among the advanced materials and aggregates washing equipment in the mining industry is the EvoWash Sand Washing Plant, known as one of the most efficient solutions for washing sand with high efficiency and modern technology utilization. This device is used for washing, dewatering, and grading mineral materials in sand and gravel mines and construction material factories and related industries.

Related Content: Crusher Machine

In this device, mineral materials pass through dewatering screens, reducing the moisture content of materials by about 12% through a specialized process. This action separates unwanted fine particles from the input materials, ultimately increasing the quality of minerals.

Notable benefits of EvoWash devices include:

1. High capacity: These devices are designed to handle a high input volume efficiently.

2. Moisture control: Optimized washing processes ensure the final moisture level is as low as possible.

3. Unique design: The planar screen of the devices is specially designed not only for efficiency but also for moisture and abrasion resistance to reduce equipment wear.

4. Trust and reliability: These devices offer high trust and reliability to users due to the quality of parts and strong design.

5. Cost reduction and efficiency increase: Using EvoWash reduces high water consumption costs and fine particles lost with wastewater, while enhancing quality and output material efficiency.

Crucial parts of the EvoWash material washing device include the input water tank, hydrocyclones, water pump, and dewatering screen. Installation, repairs, and maintenance of these devices are also very straightforward and do not require specialized expertise due to their unique design.

Considering the advantages and capabilities of this device, it is highly recommended as a suitable alternative to traditional sand-washing systems because it not only reduces costs but also improves material quality and efficiency.

Thickener (Thickener)

The thickener (Thickener) is one of the materials and aggregates washing equipment in sand and gravel mines, a vital tool in the mining industry for water recovery and reuse. By using the settling process, this device helps us attain purified water. In many cases, particles and solids present in mine and factory water can lead to clogging and blocking pipes and equipment. In such situations, using a suitable thickener sand washer can significantly reduce the amount of suspended particles.

This device is mainly known as a protective solution for water resources, as it minimizes industrial water pollution. Although often used to reduce pollution, note that this device does not affect bacteria or water sterilization, but only removes suspended particles from the water.

Thickeners are categorized based on their material and application as follows:

1- Standard Thickener: This type of thickener separates small solids from wastewater using settling and centrifugal force. The settled particles are then extracted from the tank, and clean water is poured through grooves into the overflow pool.

2- Plate Thickener: This type also separates suspended particles from water using a similar process.

3- High-Flow and Deep Conical Thickeners: These thickeners operate automatically and occupy a small area. Additionally, with sloped outlet plates, they facilitate easier water discharge.

4- Lamella Thickener: This thickener is mainly used for treating high-concentration wastewater, with its tank surface adjusted according to the wastewater capacity.

Overall, thickeners can effectively separate suspended particles using centrifugal force and gas. By adding flocculant polymers, suspended particles become heavier and easily settle. Once gathered, settled particles are directed to their designated pool using paddles.

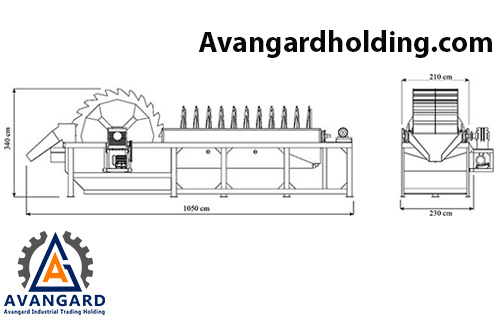

Technical Specifications of Sand Washer

The sand washer is crucial equipment in sand and gravel mines used for washing and cleaning sand from soil and various contaminants. This machine typically uses a powerful irrigation system to wash the sand with high-pressure water.

Technical specifications of the sand washer may include the following:

1. Capacity: Usually refers to the tonnage of sand per hour or day. This amount is typically determined based on the mine's production needs and the device's capability.

2. Dimensions: Vary and depend on the type and size of the sand and the mine's spatial requirements.

3. Motor power: Usually specified based on the sand's volume and the needed water pressure.

4. Water pressure: An essential parameter, as high pressure is necessary for effective sand washing. Typically provided by high-pressure pumps.

5. Water consumption: Important and should be optimized to conserve water resources.

6. Body material: Usually made of robust materials like steel to resist impacts and corrosion.

7. Control system: Some sand washers feature smart control systems, improving performance and reducing water and energy consumption.

These specifications can vary based on the type and model of the sand washer and be adjusted based on specific mining and production needs. For example, single spiral sand washers with technical specifications ranging from lengths of 6, 7, 9 meters and widths from 80 to 140 cm, with capacities from 5 to 60 tons per hour, depending on factors such as spiral diameter, length, and rotation speed, as well as the number of spirals and the volume of the incoming water tank, are produced. Bucket wheel sand washers with a capacity of approximately 80 tons per hour are also available. For catalog requests and price quotations regarding sand washer purchases, you can contact Avangard's sales experts.

Technical Specifications of a Type of Sand Washer

How a Sand Washer Works

The crusher sand wash machine operation involves several stages:

1- Pre-wash and screening: Sand enters the sand washer for initial cleaning and screening, separating materials larger than a specified size and discarding them.

2- Washing and grinding: Sand with water and cleaning agents is directed into the device, processed using a specialized washing and grinding device. This process cleans materials, separating worn-out and contaminated particles from the stones.

3- Discharge and drying: After processing, sand is expelled from the device for drying towards the discharge. This stage can involve transferring via conveyor belts or a drying system.

Crusher sand wash machines use these processes to produce clean, high-quality sand for use in various industries, ultimately creating usable sand for different sectors.

Advantages of Sand Washer

Crusher sand wash machines have numerous advantages, including:

1- High efficiency: These machines can consistently wash and grind stones and sand with high quality, increasing productivity and reducing material waste.

2- Cost reduction: Using a crusher sand washer, you can reduce costs related to purchasing sand and gravel and also save labor costs.

3- Environmental protection: With advanced technology, these machines help reduce discarded and contaminated materials, aiding in environmental conservation.

4- Flexibility: These machines can be adjusted for different industrial needs, offering the best performance.

5- Output quality: Using crusher sand washers can produce high-quality sand free of impurities, valuable for various industries.

فارسی

فارسی  Arabic

Arabic