[rank_math_breadcrumb]

Crusher devices are essential tools in mineral processing, used for crushing and reducing the size of raw materials extracted from mines to desired sizes. These devices, such as jaw crusher, cubit, hydrocone, and rock and rock crushers, can crush various types of stones based on their hardness, dimensions, abrasion, and moisture content. Each type of crusher, depending on specific needs and applications, has its own unique advantages and features.

Avangard Holding, with more than two decades of experience in the mining industry and utilizing technical knowledge and academic education from reputable domestic and foreign universities, produces and supplies various industrial crusher devices for iron ore mines and sand-making machines. The company, with spare and consumable parts, is ready to provide services to esteemed industrialists and assists buyers in selecting the best equipment for their needs with specialized consulting.

Purchase and sale of crusher devices (crushers) in Avangard Holding is done with a quality guarantee and technical support. Our goal is to provide the best stone crushing solutions and improve the sand-making process in various industries.

Purchase Various Crusher Devices from Avangard

For purchasing crusher devices or consulting for the selection of sand and gravel mining equipment in any part of the country and aiming to buy the best and highest quality crusher device, Avangard Holding offers various crusher devices at your disposal. You can visit the Avangard Holding website, select your desired products online, and receive them as quickly as possible.

Crusher Device Price

The price of crushers can vary significantly and depends on multiple factors including the type of device, production capacity, technical features, manufacturer brand, market conditions, materials, and parts used in its construction, etc. The price of a sand and gravel crusher or sands crusher machine varies depending on the type and capacity of the device. Smaller crusher devices are also used for their specific applications, and their prices are more reasonable. For those intending to purchase a jaw crusher or other types of crushers, thoroughly reviewing the features and needs is very important. The price of tractor crushers is also very suitable for some small mines and projects due to their ease of transportation.

Related Article: Screen Device

To find out the price of the crusher device, you can contact the reliable supplier and manufacturer Avangard or visit the Avangard Holding website and proceed with the purchase. It should be noted that installation, transportation, and maintenance costs can also be calculated separately and should be considered in the overall price calculation.

| Row | Description | Price |

| 1 | Price of Bohringer Crusher Device | Please Call |

| 2 | Price of Hydrocone Crusher Device | Please Call |

| 3 | Price of Gyratory Crusher Device | Please Call |

| 4 | Price of Jaw Crusher Device | Please Call |

| 5 | Price of Cubit Crusher Device | Please Call |

| 6 | Price of Rabbit Crusher Device | Please Call |

|

7

|

Price of Rock and Rock Crusher Device | Please Call |

Types of Crusher Devices

Crushers are categorized based on the type of use. Different types exist depending on location, type of stone, budget, production method, etc. Crusher devices are used in many industries, including construction, cement industry, sand and gravel industries, chemical industries, mineral processing, and various mines including coal, gold, copper, iron ore, etc., to crush stones to an acceptable size for further processing. Various types of crusher devices are produced, each performing different tasks. These types include Bohringer crushers, gyratory crushers, jaw crushers, cubit crushers, hydrocone crushers, rabbit sand makers, and rock-and-rock sand makers. These devices are available at Avangard company for preparation and sale. For more information about prices and purchase and manufacture of crusher devices, you can contact Avangard company's experts.

Related Article: Feeder Device

Bohringer Crusher Device

Bohringer Crusher Device is used for crushing mountain or river materials or, in other words, for crushing stones with medium-hard, hard, and very hard hardness coefficients like limestone, basalt, and granite. Bohringer crusher falls into the category of impact crushers. The hammer crusher or cubit crusher comprises a rotor with several rows of hammer blades that rotate at high speed. The role of hammer blades is to throw the incoming load pieces (stone and minerals) towards the inner casing of the crusher. With the rotor's spin and the stones' throw to the walls and anvils, the crushing operation is done.

One of the advantages of impact crushers is the output grain size adjustment, which can easily be adjusted by the crusher regulation system. These types of crushers are very heavy and powerful and can produce products in high volume. Bohringer crushers are produced in various models of HS impact crushers including HS7-HS10-HS11-HS14-HS16 and PST Impact Crusher - DMK Impact Crusher - PF Impact Crusher models. Among the most important parts of the Bohringer crushers are the crusher hammers, which are crucial due to their wear resistance. They are used to produce cubic sands with high precision from hard, heavy, and large stones. These hammers are used for their specific features such as high erosion resistance, appropriate for this application. In Avangard company, the alloy used in Bohringer crusher hammers includes manganese steel, Ni-hard cast iron, manganese-molybdenum steel, and chrome or high-chrome cast irons, which increase their life span and durability. These hammers have higher resistance and strength compared to other crusher hammers and can be purchased by contacting Avangard sales experts.

Gyratory Crusher Device

Gyratory Crusher Device, or superior crusher, was produced as the first type of this device in 1878. It is used as a primary crusher in large establishments and situations that require more capacity and crushing than some jaw crushers. This type of crusher consists of a fixed cone-shaped body and a central core with a gyratory movement (rotational movement around its axis). The angle between the fixed body and the moving core is about 22 to 30 degrees. Minerals are crushed in the space between the fixed body and the moving core. When the moving core moves towards the body, materials in that section are crushed, while in the opposite section of the moving core and stationary body, the space increases, allowing materials to move lower and fill the space. Thus, the crushing operation is carried out continuously with uniform force. In this type of crusher, like jaw crusher devices, there is no need for a feeder, and it can be directly fed by large trucks in mining industries from multiple directions, ensuring materials are evenly distributed and crushed inside the crusher. This device is produced in various types of gyratory crushers, including based axis and hanging axis models. Popular models include the 36*9 Superior (Gyratory), 36*11 Superior (Gyratory), and 36*13 Superior (Gyratory), available at Avangard at a suitable price.

Jaw Crusher Device

Jaw Crusher Device is one of the crushing devices used as a primary crusher. With an open mouth, which forms a space between two jaws at the top part, it provides a proper function for mountain and river stones. In the primary stage (primary crushing), large pieces resulting from shooting or extraction with natural dimensions for reducing size of minerals and rocks to various dimensions that can be easily transported by conventional means such as conveyor belts and moved to the next stage (secondary crushing), are used in crushing systems in sand mines and other extraction workshops. These devices apply compression and crushing and, using shear and compressive forces, crush materials and rock pieces in the crushing chamber. In a jaw crusher, the gap or cavity between the two jaws is called the crushing chamber. One jaw is fixed, while the other is movable, which shifts through a cam mechanism, with the movement of the movable jaw provided by an external shaft connected by a belt and pulley to a motor. The movement of the movable jaw may be very slight as the complete crushing process is not completed at one time. In order to provide the inertia needed for crushing materials, a gear is used that moves a shaft through its movement. This gear movement causes an off-center force. This off-center force causes the space to close, and with this operation repeated, materials can be crushed to the desired size and eventually exit through the bottom opening of the crusher, known as the discharge opening or throat.

Related Article: Sand Washer Device

Some of the most common Avangard jaw crushers include: 20*30, 30*50, 40*60, 45*65, 55*80, 30*90, 50*90, 60*90, 70*90, 30*125, 80*100, 90*110, 40*90, 63*100, 100*120, etc., named based on their input open dimensions. For example, a crusher with dimensions 55*80 means its input opening has these dimensions. Contact our experts for purchasing and manufacturing jaw crusher devices and jaw crusher spare parts.

Cubit Crusher Device

Cubit Crusher Device is a type of impact crusher that crushes rock pieces using impact force. This horizontal device performs crushing based on rotor movement and speed. Cubit crusher can be used as a primary, secondary, or even tertiary crusher. This device crushes mining and river stones between 10 to 15 cm in size. The cubit crusher includes a rotor comprising 2 to 6 rows of hammer blades rotating at high speed. This device is used in sand, lime, and gypsum mines to crush medium-sized soft ores, turning them into fine sand grains, noodles, and pebbles. The role of hammer blades or cubit hammers is to throw incoming load pieces towards the inside wall of the crusher. In impact crushers, cubit crusher hammers are designed and positioned in a single row inside the crusher for crushing. When the feed enters the device, stones are thrown by the hammer, hitting the cubit anvil and getting crushed. Among cubit crusher models are jack models and ordinary models, both featuring bodies with the capability of reopening and folding. These devices also provide the ability to replace parts, upgrade the device, and adjust exit screws to control the size of the exit materials. The sale of various types of cubit crusher devices in two types, simple and hydraulic, and in one-sided and double-sided models with capacities of 80, 100, 120, 180, 240, and even up to 300 tons per hour at the best price is available at the Avangard company. For product ordering, manufacture, and purchase of cubit crusher devices and cubit crusher spare parts, please contact Avangard.

Related Article: Casting Services

Hydrocone Crusher

Hydrocone crusher is one of the significant equipment in the mining industry for crushing and breaking minerals such as rocks. This device is commonly used as a secondary crusher in mines. Since the input and output dimensions of the device can be adjusted by changing the size of the concave and mantle, it can be easily used for various applications. Due to its hydraulic system, this crusher is known as "Hydrocone". During the crushing process, the moving part called mantle approaches the fixed part known as concave, reducing the gap between them. This action causes the minerals to be crushed. Hydrocone is used as a crushing and breaking device for minerals, and it also helps in the production of sand and gravel.

There is a wide variety of Hydrocones, and companies manufacture and offer different models with various dimensions and features. Common dimensions include 36 inches, 45 inches, 48 inches, 54 inches, and also Symons crushers (Symons Hydrocone) 66 inches and 84 inches. Among these, the 36-inch size is common in various types such as 2-36, 4-36, 5-36, 5/5-36, 6/5-36, and 8-36, which are known respectively as fine crusher, medium crusher, and coarse crusher. At Avangard, various Hydrocone crushers and spare parts are available, and you can contact sales experts for price inquiries and purchases.

|

Specifications of 36-inch Hydrocone Crushers

|

|||||||

| No. | Model | Max. Input Size (mm) | Output Sizes (mm) | Production Capacity (t/h) | Motor Power (kw) | Weight (ton) | Dimensions (Length*Width*Height) (cm) |

| 1 | Fine Crusher 2*36 | 40 | 0-30 | 80 | 90 | 11 | 380*190*300 |

| 2 | Fine Crusher 4*36 | 60 | 0-30 | 100 | 90 | 11 | 380*190*300 |

| 3 | Medium Crusher 5*36 | 100 | 0-30 | 140 | 90 | 11 | 380*190*300 |

| 4 | Coarse Crusher 7*36 | 160 | 0-50 | 160 | 90 | 11 | 380*190*300 |

| 5 | Coarse Crusher 8*36 | 200 | 0-60 | 180 | 90 | 11 |

380*190*300

|

Derezzor Sand Maker

One of the types of impact crushers is the Derezzor Sand Maker. In these devices, the impact force causes the crushing of materials, stones, and minerals. This device is commonly known as the Derezzor Sand Maker and, unlike other impact crushers, features a vertical shaft, with its rotor spinning and rotating around this axis. Sand makers are used as crushers for producing crushed sand in mines and have various capabilities, including crushing non-sticky dry materials with a strength of up to 450 MPa, suitable for materials such as quartz, basalt, limestone, and granite. The estimated net production of this device is up to 30 tons per hour, with an input load dimension limit of 50 mm and output down to under 15 mm (with more than 60% of the output below 6 mm). Advantages of the Derezzor Sand Maker include easy replacement of spare parts, easy installation and setup, and low vibration performance. For purchase and price inquiries, you can contact the sales department and receive technical advice.

|

Technical Specifications of Derezzor Sand Maker

|

||||||

| No. | Model | Max. Input Size(mm) | Output Sizes(mm) | Production Capacity(t/h) | Motor Power(kw) | Weight(ton) |

| 1 | Derezzor Sand Maker | 0-50 | 0-15 | 30 | 75 | 4.5 |

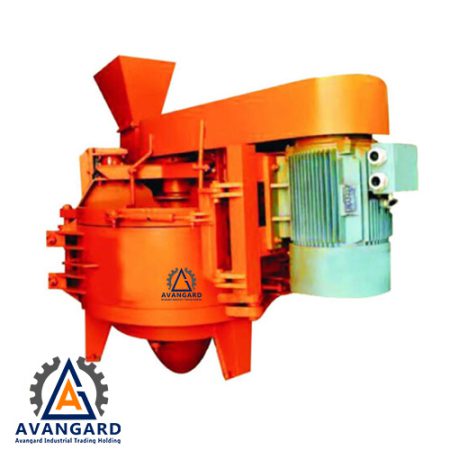

Rock and Rock Sand Maker

Rock and Rock Sand Maker is one of the critical equipment in the crushing and construction materials industry. This device is used for crushing materials and fine grains with dimensions between 6 mm and 30 mm, resulting in final product diameters ranging from 0 mm to 6 mm. This crusher uses hammers rotating at high speed around their vertical axis to crush materials. This rotation creates centrifugal force that aids in the crushing process. To ensure optimal performance and long lasting operation, the material of these hammers and the rotor is crucial. Hammers are made of tungsten carbide, while the rotor, which is the more critical part, is made of materials like Hardox 400, which are abrasion-resistant. The Rock and Rock crusher can serve as both a primary and secondary crusher, producing high-quality combination loads in multiple forms. This device is used according to modern sand and gravel production standards for various industries such as asphalt and concrete. Additionally, the Rock and Rock Sand Maker, also known as the Centrifugal Sand Maker, is very applicable for the crushing of hard materials such as feldspar, silica, dolomite, barite, etc. In conclusion, this device is produced in three models: V8, V10, and V10H, and industrial professionals can contact the sales unit for advice, purchase, and price inquiries.

Applications of Crusher Devices

Crusher devices are among the essential tools used across a range of industries, including mining, construction, material processing, cement industries, building construction, various mines, such as sand and gravel mines, etc. These devices are employed for breaking and crushing rocks and heavy materials. There are several types of crushers, each with specific features and applications.

1. Impact Crusher: This device uses a rotating rotor and impact hammers and anvils to break and crush rocks.

2. Gyratory Crusher (Superior): This device employs gyratory motion to crush rocks.

3. Jaw Crusher: Uses moving and fixed jaws to compress and crush materials.

4. Cone Crusher: Uses a moving cone and a fixed inner wall to crush materials.

5. Vertical Impact Crusher: Used for sand production from crushed rocks.

6. Rock and Rock Crusher: Another type of sand maker used for sand production from crushed rocks.

7. Mobile Stone Crusher Machine: Designed for easier movement and relocation in various environments and used for rock and material crushing.

Crusher devices are used according to the material type and user needs, playing a crucial role in industrial processes.

Technical Specifications of Crusher Devices

Crusher devices are manufactured in various types for different industrial uses, but some common technical specifications that may be considered include:

1. Capacity:

The capacity of a crusher is measured based on the volume of material it can crush within a certain timeframe. It is usually measured in units of weight or volume (such as tons or cubic meters per hour).

2. Input Material Dimensions:

The crusher device must be capable of accepting materials with specific dimensions. The input material dimensions may be determined by the dimensions of its jaws or the device's entry portal.

3. Output Size:

The size of materials exiting the crusher needs to be adjustable. Some crushers have the capability to adjust the output size.

4. Type of Materials to Crush:

Some crushers are suitable for crushing soft materials like limestone and gypsum, while others are more appropriate for hard materials like heavy rocks and ores.

5. Motor Power:

The motor power of the crusher device is determined based on the mechanical power required for crushing materials. This motor usually operates according to a specified voltage and frequency.

6. Control System:

Some crushers possess intelligent control systems, allowing the user to adjust and manage the device's performance. These systems may include digital displays, sensors, and automatic controls.

7. Energy Consumption:

The energy consumption of the crusher device is also a significant consideration because it can have a substantial impact on operational costs. These are just some general technical specifications, and depending on the type of crusher and the industry used, there are additional technical specifications you can obtain by visiting the sand and gravel equipment sales page or by contacting Avangard's technical and sales team for more detailed information, eventually leading to purchasing.

فارسی

فارسی  Arabic

Arabic