[rank_math_breadcrumb]

Conveyor Belt

The material transfer machine or conveyor device, known as a conveyor, comprises moving plates made of durable rubber and metal, driven by a motor and gearbox. It’s part of the sand and gravel mining equipment. This equipment is used for moving and transferring goods, products, and packages. Depending on the application, conveyor length, product weight, and type, conveyor types can vary. Conveyors can be inclined or flat. The belt material can be PVC, metal, or mesh. In sand and gravel mines, conveyors are used to transfer processed minerals from primary crushers to secondary crushers.

What is a Conveyor?

A conveyor, a device made of a moving plate, was first developed in 1892 to speed up and simplify material transfer between locations in mines. Conveyor belt development peaked in the nineteenth century, with Richard Sutcliffe developing a coal conveyor belt in 1905, revolutionizing the industry. Today, conveyors are crucial in the transportation systems in mineral processing plants and various industries, such as cement, sand and gravel, food, pharmaceutical, chemical, and tire manufacturing. They are designed to withstand the weight and pressure of the materials. Conveyors are designed with various speeds and capabilities to suit environmental and production process needs. We will briefly explain their types, and you can contact the Avangard sales department for inquiries about conveyor machines and spare parts, including the conveyor belt, rollers, drum or roller shaft, and conveyor motor gearbox.

Types of Conveyor Machines

Avangard Holding is a manufacturer and supplier of various conveyors and conveyor equipment, including:

- Roller Conveyor

- Belt Conveyor

- Chain Conveyor

- Screw Conveyor

Types of Conveyors

Roller Conveyor

A type of conveyor known as a roller conveyor consists of several rollers used for moving bulky and heavy items with flat surfaces over short distances. This roller conveyor uses gravity to move items manually without a motor-driven force.

Belt Conveyor

In various industries, belt conveyors are used for transferring bulk or packaged materials. Besides material transport, they are also used for sorting or separating materials.

Related Article: Screening Machine

Chain Conveyor

Chain Conveyor

A type of conveyor known as a chain conveyor provides more flexibility than other conveyors due to its chain-driven mechanism. It's suitable for long-distance material transfer, such as moving minerals from extraction sites to processing facilities.

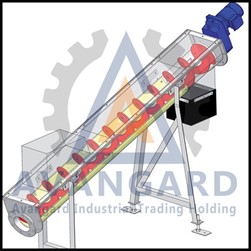

Screw Conveyor

The screw conveyor, commonly called the material transfer auger, is a device for moving bulk fine and powdery materials over short horizontal and vertical distances. It consists of a very robust metal spiral blade that rotates to move materials. Screw conveyors can be manufactured in various forms, including:

1. Vertical Screw Conveyor

2. Horizontal Screw Conveyor

3. Shaftless Screw Conveyor

4. Inclined Screw Conveyor

5. Flexible Screw Conveyor

6. Tubular Screw Conveyor

7. U-shaped Screw Conveyor

8. Portable Screw Conveyor

9. Fixed Screw Conveyor

These devices are used to move materials in various industries, including mining, agriculture, food, and chemical industries.

Dear industry professionals, you can contact the sales department to receive catalogs, manufacture, and purchase various conveyor machines or spare parts, including Roller Conveyors, Belt Conveyors, Chain Conveyors, Screw Conveyors, and more.

Types of Conveyors Based on Application

Loader Conveyor System

In various industries, especially at mineral processing plants like cement, loader conveyors are used to increase speed and efficiency during loading processes. These conveyors load goods onto trucks or load excavated soil from mines.

volumes to avoid occupying too much space for conveyor installation.

alttoo much space for conveyor installation.

In various industries, especially in bean and fruit production factories, hand picking belt conveyors are used to inspect products and separate impurities and stones.

Rotary Conveyor

A rotary or spiral conveyor is another type of conveyor capable of rotation and adjusting in curved and spiral forms. It's used in industries with high workload volumes to avoid occupying too much space for conveyor installation.

Incline Conveyor

An incline conveyor is a specific type of conveyor used for loading and transferring materials on inclined paths or between floors.

Gravity Conveyor

Materials and products on gravity conveyors are transferred using gravitational force. By creating an incline, materials and products move on conveyor rollers.

Related Article: Feeder Machine

Magnetic Conveyor

Magnetic conveyors are used for transferring metal materials and products like cans, magnetically charged stones, and other materials and for separating magnetic materials from others. These conveyors can transport materials vertically, inclined, or even upside down.

Trough Conveyor

The chassis of this type of conveyor is made of trough profiles and is often designed for incline use. These conveyors can transfer large volumes of materials and goods in various systems, including mines.

Bucket Conveyor

A bucket conveyor consists of a series of buckets used for moving bulk and powdery materials such as sand, cement, pulses, and similar products. These conveyors are used in industries such as storage, loading and unloading ships, woodworking, foundry, recycling, and mining. Additionally, bucket elevators exist, resembling bucket conveyors, made from buckets used for vertical material transfer.

Types of Conveyors Based on Driving Force

Electric Conveyor

Electric conveyors require electrical power for operation and use electric motors to move the conveyor belt.

Gravity Conveyors

Gravity conveyors are a type of roller conveyor that moves materials using gravitational force and material weight, operating without the need for electric motors. These conveyors are placed at an angle, and materials move along them. Additionally, human force can move materials on the conveyor over horizontal paths. The gravity conveyor is among these types.

Technical Specifications of Conveyor Machines

Conveyors are produced and marketed in various dimensions and sizes based on different projects and industries' needs. They usually range in length from 1 to 2000 meters and in width from 40 to 250 centimeters. Material transfer capacity varies for different conveyor types, ranging from 500 to 5000 cubic meters per hour. Conveyors can carry raw materials, minerals, products, etc., in bulk or packaged along horizontal and inclined paths.

The table below shows the minimum and maximum belt speed and width based on the type of transported materials:

Technical Specifications of Conveyor Machines

| Material | Belt Speed (Feet per Minute or fpm) | Belt Width (Inches) | ||

| Minimum | Maximum | Minimum | Maximum | |

| Grains, seeds, and other free-flowing non-abrasive materials | 500 | 1000 | 18 | 96 |

| Aggregate stones, coal, soft ores, wet clay | 400 | 1000 | 18 | 72 |

| Heavy and hard ores, crushed stones | 350 | 600 | 18 | 36 |

Conveyor Structure

The conveyor or belt's structure is made of steel or other materials, including cylinders, straps, rollers, and conveyor belts, designed to support load weight and provide conveyor movement, as detailed in the image below.

Conveyor Components

In the industry, conveyor systems are typically composed of five main parts:

Conveyor Frame

All conveyor components and parts are mounted on the frame. The conveyor frame is usually designed and manufactured in three models: tubular, profile, and trough, with different uses.

Tubular Conveyor Frame

The tubular conveyor frame is used for transferring mined materials like sand, coal, lead, zinc, iron ore, etc. Due to its high strength, tubular frames are also commonly used in concrete manufacturing plants or batching plants.

Profile Conveyor Frame

The profile chassis, due to its lightweight feature, is often used in mobile conveyors. This type of chassis is used for transferring powdery and granular materials and is widely used in production and assembly lines.

Trough Conveyor Frame

In addition to being lightweight, the trough chassis is highly robust and can be used for long-distance material transfer.

Related Article: Sand Washer

Conveyor Belts

Belts are the moving parts of conveyors that transfer materials through direct contact. Manufactured in various materials, colors, and sizes, these belts are used across different industries.

Types of Conveyor Belts by Application

In food, healthcare, and pharmaceutical industries, PVC and fabric conveyor belts are used. Rubber conveyor belts are used in mines and mineral industries for transporting materials like coal, cement, lime, and more. Metal belts are used for moving substances like water or oil and can withstand high temperatures. Each type of conveyor belt has different applications based on the needs of various industries and sectors.

- Rubber Conveyor Belt (EP Conveyor Belt)

- PVC Conveyor Belt (PVC Conveyor Belt)

- PU Conveyor Belt (PU Conveyor Belt)

- Metal Conveyor Belt

- Modular Conveyor Belt

- Silicone Conveyor Belt

- Canvas Conveyor Belt

- Fire-Resistant Conveyor Belt

- Fabric and Felt Conveyor Belt

- PVG Conveyor Belt

- Patterned Conveyor Belt

Conveyor Roller and Idler

A wide variety of rollers and idlers are used in conveyors to move and adjust the movement of the conveyor belt and reduce component friction. These include ball rollers or drums, load-carrying rollers, return rollers, drive rollers, belt tension adjustment rollers, and Snub rollers. These names are used for different applications of rollers in conveyors.

Drum or Ball Roller (Conveyor Drum)

Drums are rollers located at the beginning and end of the conveyor belt to facilitate movement and change the direction of the belt. These drums rotate continuously and are also known as the initial and terminal rollers of the conveyor belt.

The initial roller typically acts as the belt driver and transfers the necessary force from the electric motor to the belt. By moving the terminal roller, the tension of the belt can also be adjusted. In some cases, such as long conveyor belts, the drive and the belt tension adjustment roller are installed separately and perform their tasks independently.

Anti Rollback Roller (Conveyor Anti Rollback Roller)

Rollers in conveyors are responsible for moving and guiding materials, reducing friction between parts and equipment. Idle rollers are used along the conveyor track, serving as rest points for the conveyor belt and assisting in material movement. These rollers are divided into load-carrying idlers and return idlers, both supporting and facilitating the belt movement. The main difference between these two roller types is their position; load-carrying idlers are on top while return idlers are below the conveyor belt, acting as the end point of the return path.

Snub Roller, another type of idler, is responsible for adjusting belt entry and exit with the lower or return path, also creating the required belt arc at the drive roller section.

The impact roller, another type of conveyor roller, is responsible for protecting the belt at loading points, preventing damage from material impacts when falling onto it.

Conveyor Geared Motor

An electric motor transmits the necessary force to move the conveyor belt via the gearbox to the drum or drive roller. The suitable motor and gearbox for conveyors are selected based on factors like conveyor length, transfer angle, volume, and type of load. Worm, helical, bevel, and parallel shaft gearboxes are among the key types used in conveyors.

Technical Specifications of Conveyor Gearboxes

| Type of Gearbox | Worm Gearbox | Bevel Gearbox | Parallel Shaft Gearbox | Helical Gearbox |

| Features | Small size, compact, inexpensive, non-reversible | High power, resistance to impact and vibration | Relatively small size, usable in space-limited locations | Relatively long drive, ability to reduce vibrations |

| Torque Capacity | Torque transfer up to 4000 Nm | Torque transfer up to 50000 Nm | Torque transfer up to 12000 Nm | Torque transfer up to 1550 Nm |

| Maximum Output Power | Approximately 6 kW | 45 kW | 15 kW | 11 kW |

| Application | Moving low to medium mass and volume materials | Transport of heavy and superheavy materials | Transport of medium mass materials | Transport of semi-heavy materials (e.g.,... |

Conveyor Systems

In conveyor belts, various systems are used for specific tasks. We will explain these systems below.

Self-Adjusting System

The self-adjusting system includes two parts: an automatic control system or tensioning screws providing the needed tension, and a gravity system supplying the required tension with weights. This system can prevent excessive friction in the conveyor belt by adjusting the tension.

Loading System

The loading system controls and regulates the process of loading onto the conveyor belt. Components like chutes, hoppers, automatic loaders, and pushers are part of the loading system in conveyors.

Portable Conveyor System

In addition to producing the required power, the portable conveyor system transfers it through a motor to the deviceâs moving rollers and idlers, causing the conveyor belt to move. Components of this system include bearings, housings, chains, sprockets, belts, pulleys, couplings, electric motors, and gearboxes.

Unloading System

Unloading systems direct and discharge materials out of the device. This system includes troughs, separators, ejectors, packagers, and other components.

Conveyor Brush Cleaner System

The conveyor cleaning system cleans rollers and belts to ensure proper and reliable operation of the device, reduce repair and maintenance costs, and extend equipment life. Scrapers and brushes are among the main cleaning devices installed on the conveyors.

Direction Change System

The direction change mechanism includes components like pushers, dampers, ejectors, and others that change the direction of loads on the conveyor belt.

Operation of Conveyor

The operation of a conveyor works as follows: the electric motor generates force and transfers it to the conveyor belt through the drive roller located at the start of the conveyor, causing belt movement. The roller or drum at the end is free and rotates with belt movement. This way, the belt rotates continuously in a closed loop, transferring materials or products placed on it.

To reduce friction and noise pollution from this process, rollers and bearings are used.

Conveyor Standards

Numerous standards by reputable organizations have been developed and documented for the design, industrial use, and safety of various conveyors and belts. Below is a table listing some of the main standards, providing industry professionals with information for confident purchasing decision-making:

Conveyor Standards

| Standard Name | Description |

| ASME B20.1-2021 | Safety standard for conveyors and related equipment |

| BS EN ISO 20238:2019 | British standard for drum belt friction tests |

| ANSI/CEMA 102-2012 | Definitions and conditions for conveyors |

| CEMA 705-2004 | Operational terms for conveyors |

| ISO 5284:1968 | Conveyor belts - list of equivalent terms |

| ISO 7149:1982 | Continuous handling equipment - safety code - specific rules |

Key Considerations in Conveyor Design and Construction

Considering the following can help in better design and more efficient construction of conveyors or belts:

1. Proper use of idlers and other parts to reduce conveyor noise pollution.

2. Designing conveyors with limited or smaller space considerations.

3. Offering simpler conveyor designs to reduce installation and start-up costs.

4. Using monitoring systems to increase speed of maintenance, fault-finding, and reduce dependency on human labor.

Choosing a Conveyor or Belt

To choose and purchase a suitable conveyor or belt, start by examining the specific industry and determine characteristics of the materials or goods for transport using a conveyor. Essential factors include material type (bulk or unit goods), dimensions and weight, chemical properties, and material temperature, along with the production rate.

Further, assess the material-transfer path and installation environment, including slope or curvature of the path, available space, and environmental conditions like humidity and temperature. These factors should all be considered when selecting a conveyor belt.

Material loading methods onto the conveyor, desired transfer speed, and depot or storage capacity are also crucial factors for consideration before purchasing, assisting in a suitable choice. Avangard's sales specialists are ready to help you select conveyors or belts with optimal pricing and quality.

Conveyor Maintenance and Repair

Given the importance of continuous conveyor operation over time, timely maintenance and repair are essential to prevent failure, work stops, and extra costs. Below are key considerations for conveyor maintenance:

1. Using appropriate conveyor belts for materials being handled and replacing them on time in various projects.

2. Fast repair of worn or torn sections on the belt.

3. Regular adjustment of belts and idlers to prevent conveyor deviation and ensure correct material movement.

4. Timely lubrication and greasing of the conveyor.

5. Protecting the conveyor from humidity and sunlight exposure.

6. Maintaining conveyors at temperatures between 10 to 20 degrees Celsius.

7. Preventing belt sagging that could lead to material jamming and belt scratches.

8. Proper installation and adjustment of cleaners to prevent vibrations or timely repairs.

9. Using grizzly screens or magnetic separators to prevent metal part intrusion.

10. Avoiding excessive belt tension.

Applications of Conveyor or Belt

Various conveyor belts can be used independently or as part of other equipment in different industries, as well as in mines, to reduce material transfer and handling costs. These conveyors are used in airports, stores, mines (mining conveyor belt for transporting extracted minerals from mines to outside the tunnel or towards processing plants), mineral processing lines, crusher lines in sand and gravel mines (crusher conveyor belt), transmission lines, production and assembly plants, loading or unloading trucks, and other transport machines or as part of different equipment (like tunnel boring machines, packaging machines, and escalators and crusher devices). Part of the application of conveyors or belts in various industries can be listed as follows:

1. Cement factories.

2. Steel plants.

3. Asphalt plants.

4. Food industries.

5. Painting industries.

6. Health industries.

7. Pharmaceutical industries.

8. Agriculture.

9. Recycling.

Advantages of Conveyor Belt

The advantages of using a conveyor belt in various industries include:

1. Reduced need for human labor in transferring and moving materials.

2. Significant reduction of operating costs.

3. No environmental pollution compared to other transport means.

4. No noise pollution.

5. Ability to transfer materials continuously and over extended periods.

6. High safety for both loads and operators.

7. Increased efficiency and productivity.

8. Preventing workforce exposure to toxic and hazardous materials.

9. Minimal space occupation.

10. Adjustable conveyor belt speed.

11. Low energy consumption.

12. Ability to transport materials in different directions.

Features of Conveyor Belt

The conveyor belt device is a crucial industry component used for transporting materials from one point to another. The main features are:

1. Transfer capability: Conveyor belts can transport materials from one place to another, including solids or liquids.

2. Flexibility: Some conveyor belts are flexible, making them adaptable for different environmental conditions.

3. Sturdy construction: Made from durable materials to support weight and operate stably.

4. Speed control: Some have speed control systems for material movement adjustment.

5. High efficiency with low maintenance cost: Typically high efficiency with minimal maintenance needs, reducing production costs.

6. Compatibility with other equipment: Can connect with other machinery like packaging or processing machines for improved production processes.

7. Suitable for various industries: Used across mining, food, automotive, and other industries; different types are available based on industrial needs.

Conveyor Belt or Parts Pricing

The prices of conveyor belt or parts are influenced by factors like:

1. Dimension and size: Length, width, and size significantly affect pricing.

2. Material and construction: Materials like steel, plastic, or wear-resistance heavily impact the final price.

3. Motor power: The motor driving the conveyor is crucial in price determination.

4. Additional and optional equipment: Such as start-up systems, safety protections, and control equipment.

5. Brand and manufacturer: Some brands generally have higher prices compared to others.

For the most accurate pricing and technical details for manufacturing and producing conveyor belts and parts, including conveyor belts, rollers, and conveyor drum or roller, gearbox motors, contact Avangard's sales specialists.

Conveyor Belt Device or Parts Pricing List

| Row | Description | Price |

| 1 | Roller Conveyor Price | Contact |

| 2 | Belt Conveyor Price | Contact |

| 3 | Chain Conveyor Price | Contact |

| 4 | Screw Conveyor Price | Contact |

| 5 | Conveyor Belt Price | Contact |

| 6 | Conveyor Roller Price | Contact |

| 7 | Conveyor Idler Price | Contact |

| 8 | Drum or Roller Conveyor Price | Contact |

| 9 | Conveyor Motor Gearbox Price | Contact |

Sale of Conveyor Belt Devices and Parts

We proudly announce that Avangard is a reliable source for purchasing conveyors and spare parts. We focus on quality manufacturing and provide solutions at reasonable prices. For further information and orders, contact us.

فارسی

فارسی  Arabic

Arabic