One of the most important materials used in construction industries is sand and gravel. These two materials exist naturally in the environment, but given the increasing need of various industries for these materials, their production activities have greatly expanded. In the process of sand and gravel production, it can be stated that natural rocks extracted from mines are used, which by undergoing processing stages, are converted into smaller particles and transformed into sand and gravel.

In nature, sand and gravel form due to the effects of wind and rain on large rocks. With the pressure and impact of rain and wind, stones exit their primary state and turn into smaller particles known as sand and gravel. In terms of size definition, sand refers to particles smaller than 4.75 mm and larger than 0.075 mm, while gravel refers to particles smaller than 75 mm and larger than 4.75 mm. These two materials are naturally found in environments such as rivers and sea coasts.

Application of Sand and Gravel in Various Industries

The use of sand and gravel in various industries is among the most critical industrial needs, and its shortage may lead to serious problems. The main applications of sand and gravel include:

1. Use in embankment dams as backfill.

2. Foundation construction in various building projects.

3. Main component in building mortar.

4. Use in concrete manufacturing.

5. Asphalt production for road construction.

6. Use in road construction.

7. Brick production.

8. Use in substructures of intercity and urban roads.

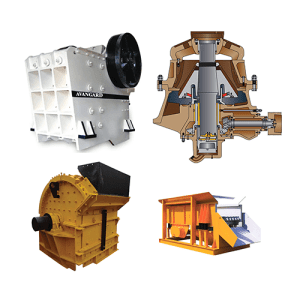

Equipment for Production in Gravel and Sand Mines

One of the crucial equipment in mineral processing lines is crushers, responsible for crushing input materials into small particles. By using other crusher equipment, in addition to reducing the size of minerals, input materials can be washed, or depending on the size, they can be separated. Crushers, based on their placement in the production line, are divided into three categories: primary crusher, secondary crusher, and tertiary crusher.

* Primary Crushers:

These types of crushers are placed in the first stage of production lines and convert extracted materials from mines into smaller pieces to be usable in other devices. One of the most used and important equipment in primary crushers is jaw crushers, which have the ability to crush very hard and tough stones due to their high power.

* Secondary Crushers:

After mineral materials are divided into small particles by primary crushers, they enter the second stage crushers or secondary crushers. These crushers further crush the stones to the size needed by other industries.

* Tertiary Crushers:

If the final output of a production line is sand and gravel or fine stones, tertiary crushers are used. These crushers are installed after secondary crushers in the production line and reduce the input materials to sizes below 0 to 6 mm.

Some crushers are not specific to a particular stage and can be used as primary or secondary crushers, like impact crushers. Each crusher has specific capacity, and their performance differs from one another. When buying, it must be determined what product the processing line will finally produce. If you intend to crush the last stage stones to the smallest possible size, tertiary crushers such as cone crushers or sand makers should be considered when designing the production line.

To purchase various crushers, crusher parts and spare parts and design the production line, you can contact the numbers listed on the Avangard website and benefit from consultations with our specialists.

Introducing Sand and Gravel Production Equipment

To produce sand and gravel and other materials in the mining and extraction industry, we should use different types of crushers and auxiliary equipment to be able to reduce the extracted mineral stones from the earth and mountains to small dimensions and separate and cleanse their impurities. Crushers and other mining equipment are manufactured in different dimensions and capacities in factories, and each production line chooses one of them based on its workshop needs. In this topic, we intend to divide crushers into three general categories named jaw crusher, impact crusher, and Hydrocone crusher, each having its subcategories which we will address, and other equipment named feeder, screen, and sand washer, which are produced in various types and play a vital role in the crushing industry, which will be briefly explained.

Types of Crushers

Crusher equipment (Crusher) is a device in the crushing and mining industry, capable of crushing large and voluminous materials and stones extracted from mines into very small pieces. Next, we will address the types of crusher equipment available at Avangard.

1- Jaw Crusher:

Jaw crusher is the first device used in mineral processing lines and sand and gravel production plants. The jaw crusher uses a fixed jaw and a movable jaw, or in other words, a fixed jaw plate and a movable jaw plate, to crush stones and has the ability to turn very hard stones into small pieces. The jaw crusher, with its very high capacity and very robust body, greatly aids in the processing lines of sand and gravel production. At Avangard, various jaw crushers in different sizes and dimensions according to the needs of that mine are produced and sold, and you can visit the jaw crusher sales page to purchase and inquire about the prices of different jaw crushers with various capacities.

2- Gyratory Crusher:

Gyratory Crusher capability is to be used as a primary or secondary crusher in mines. This type of crusher has a high ability to crush very hard materials, substances, and stones. The gyratory or rotary crusher is among the devices usually installed in the first stage of processing lines and has the ability to crush very large stones. When a factory or extraction workshop requires a device with very high capacity, it usually uses a gyratory crusher (rotary crusher). Along with the numerous features of the gyratory crusher, this crusher is occasionally used for sand and gravel production.

4- Kubit Crusher Device:

Kubit Crusher device is one of the most used types of crushers, known for its ability to crush stones with the help of hammers. Kubit crushers are offered in various capacities and can crush a large amount of stone per hour. The incoming stones are crushed inside the crusher by hammers mounted on the rotor and side plates placed inside the main anvil, delivering a uniform and sharp output. The Kubit or impact crusher has a long lifespan and, due to its high capacity, increases the speed of sand production. Various sizes and dimensions of Kubit crushers are produced and sold at Avangard, tailored to the needs of the mine, and you can visit the Kubit crusher sales page for purchasing and price inquiries.

5- Bohringer Impact Crusher:

Bohringer Impact Crusher (known as HS Bohringer impact crusher in Iran) is one of the impact crushers used to crush mountain or river stones up to 300 mm in diameter to transform them into sand. Among existing impact crushers, this crusher utilizes the latest technology. HS Bohringer Impact Crusher is suitable for crushing hard and semi-hard materials like iron ore, limestone, cement stones, and other hard-resistant materials. Various sizes and dimensions of HS Bohringer impact crushers are produced and sold at Avangard, catering to the needs of the mines (HS7 | HS10 | HS11 | HS14| HS16), and you can visit the Bohringer crusher sales page for purchasing and price inquiries.

6- Sand Making Machine:

The sand crusher device converts extracted stones from jaw or impact crushers into much finer particles. Typically, the sand obtained from sand maker outputs has a size between 0 and 6 mm, with most having an average capacity of about 30 tons per hour. It is noteworthy that sand making devices, depending on their function, capacity, and even appearance, are produced in three types: rock to rock sand makers, rabbit sand makers, and pocket sand makers (in two models 4-hammer and 6-hammer), each having different performances and production capacities.

Types of Crusher Screen Devices

Industrial screen devices are used to sieve raw materials to separate large and small particles. In the mining industry, especially in sand mining, besides transporting materials, screen devices are used for separating stone, soil, metal, different minerals, etc. It is noteworthy that crusher screen devices are used in industries and factories for differentiating large particles and their classification.

1- Vibrating Screen Device:

Vibrating Screen Device, or vibratory screen, uses vibrating motions to screen and separate materials. In the crushing and screening industry, the vibrating screen can be constructed in multiple layers to separate materials with specific dimensions, with the final output being classified as it exits the device.

2- Rotary Screen Device:

The rotary screen device is a cylindrical, horizontal device used in the crushing and screening industry. It rotates around its axis and, through its rotational movement, can separate and screen different materials, including minerals, soils, fertilizers, and more.

3- Grizzly Screen Device:

Grizzly screen device is typically used to separate soil and fine rock particles from larger rocks. With its robust structure and inclined surface, it is very suitable for the initial separation of coarse materials from finer ones. The grizzly screen is considered one of the widely used devices in the crushing and grading industry.

Types of Sand Washer Devices

A sand washer or washing device is used for washing and cleaning sand from impurities, thereby improving the quality of sand or aggregates in mines. The sand washer is usually placed after the screen device in the crushing and processing equipment and uses water to wash and separate sand and gravel from dust, mud, and other impurities. Below are the types of sand washing devices.

1- Single Spiral Sand Washer:

In the single spiral sand washer, sand and gravel with impurities are directed into the washing tank of the single spiral device, and after completing the washing stages, using the single spiral present in the device, they are led towards the outlet. The sand and gravel are completely cleaned of any dust with the help of the spiral blade, making the single spiral sand washer a popular device in the crushing industry in mines.

2- Double Spiral Sand Washer:

The double spiral sand washer operates similarly to the single spiral model but is used for materials with high impurities where the single spiral type cannot handle the quantity. In situations where defined sand and gravel have a significant amount of additional materials, the double spiral washer is a suitable option, washing materials with two spirals in sand and gravel mining operations.

3- Scrubber Mixer Sand Washer:

The scrubber mixer or rotary scrubber is a cylindrical or rotary device used in sand and gravel mining for washing materials, minerals, coarse aggregates, and crushed rocks, and for cleaning materials from soil, mud, and other adhesive particles, enhancing their quality.

4- Bucket Wheel Classifier Sand Washer:

The bucket wheel classifier is another type of sand washer used in mining operations for its high production capacity and is typically employed for high production tonnage. It is commonly used for washing aeolian sands, which form along seashores or rivers. This model uses a rotary wheel instead of a spiral blade and is therefore referred to as the bucket sand washer. The system includes three water outlets and two inlets, enabling multiple stages of washing, leading to an exceptionally high-quality product.

5- Thickener Device:

The thickener device is used in sand washing operations in the mining industry to purify wastewater from processing plants, especially in crushing and mineral processing workshops. The thickener separates solid particles from liquid in minerals using centrifugal and gravitational forces, notably preventing environmental pollution and water wastage.

6- EvoWash Sand Washing Plant:

The EvoWash Sand Washing Plant is a dynamic sand washer featuring a modern design. Besides washing fine aggregates and sand from impurities and sludge in minerals, it reduces moisture volume and classifies injected mineral materials. Sometimes known as a dewatering or drying screen in the crushing industry.

Feeder Devices in Sand and Gravel Mines

The feeder device, literally meaning a feeder, is a device in the crushing industry used for separating and sorting materials and transferring them for organized and uniform entry into other devices, particularly primary crushers like jaw crushers. Different types are produced and sold, and we will briefly explain each type below.

1- Vibrating Feeder Device (Vibrating Feeders):

The vibrating or vibratory feeder device is one type of feeder used in the crushing and mineral processing industry to introduce or inject materials into initial crushing lines in crushers. It directs materials with vibrating movements towards the target feeding equipment.

2- Grizzly Feeder Device (Grizzly Feeders):

The grizzly or network feeder device, often known as the mountain or sand and gravel feeder, is used in the mining industry to separate materials for orderly and uniform entry into other devices, particularly primary crushers.

3- Shutter Feeder Device:

The shutter or reciprocating feeder device is used for feeding crushing devices. Its back-and-forth movement enables the transfer and direction of materials towards other devices, favoring volumetric, moist, and sticky materials.

Conveyor Device

Belt conveyor or conveyor device is used to facilitate and secure the transportation of parcels, enhancing work efficiency. Made of a movable plate, it is widely used for moving and transferring materials and products across various industries, including mining, mineral processing, food, chemical, pharmaceutical, tire manufacturing, and others. You can visit the conveyor sales page for orders, manufacturing, inquiries, and purchasing.

1- Fixed Loading Belt Conveyor Device:

The fixed belt conveyor device, sometimes referred to as a conveyor belt, is a highly practical tool for object transfer, utilized across various industries. It is one type of conveyor produced in different widths and lengths up to 2000 meters, used in a fixed position with varying loading capacities from 1 to 250 tons per hour. Designed to function horizontally or even on a slope or a combination, it's particularly used in sand and gravel mining.

2- Mobile Loading Belt Conveyor Device:

The mobile loading belt conveyor device is commonly used for loading and transferring materials where the conveyor must be positioned at varying distances to transport the load into vehicles. Mobile conveyors can be equipped with features like conveyor rotation, height adjustment, and speed changes according to the type of product.

Purchase of Sand and Gravel Mining Equipment

For designing sand production lines, purchasing, and setting up sand and gravel mining equipment, consult with our experts. Avangard will support you from the start to the project's end for setting up a productive sand and gravel plant, even supplying consumable crusher parts after the mine setup. Contact our sales experts now for manufacturing orders, inquiries, and equipment purchases.

فارسی

فارسی  Arabic

Arabic