[rank_math_breadcrumb]

Conveyor and elevator parts, or in other words, spare parts for industrial conveyor belts or conveyors and elevators, which are used in conveyor and industrial belt conveyor machines, are among the first and most effective technologies for material transfer in various industries. These systems, by increasing productivity and accuracy in material transfer, play a significant role in improving industrial performance. To maintain the optimal performance of this equipment, purchasing high-quality conveyor belt parts and selling conveyor parts is very important.

You, esteemed industrialists, can purchase conveyor belt equipment and elevator parts, including conveyor belt equipment such as conveyor belt roller bases, conveyor belt rollers (upper, lower, transfer, diverter, and rubber retaining rollers), conveyor or elevator chains, sun gears, fixed and moving rollers, electric motors, buckets, conveyor clamps, conveyor belt rubber, canvas belts, magnets, belt fasteners, vulcanizing glue, and various gearboxes, while maintaining high quality and reasonable prices.

Avangard Company also accompanies you in the field of manufacturing conveyor belt rollers and providing various types of mineral conveyor belts and small and large conveyor belts in various sizes such as 3 meters. You can contact Avangard Company sales experts to find out the price of conveyor belt or conveyor belt accessories, receive conveyor belt specifications and types of industrial conveyors, and experience a safe purchase.

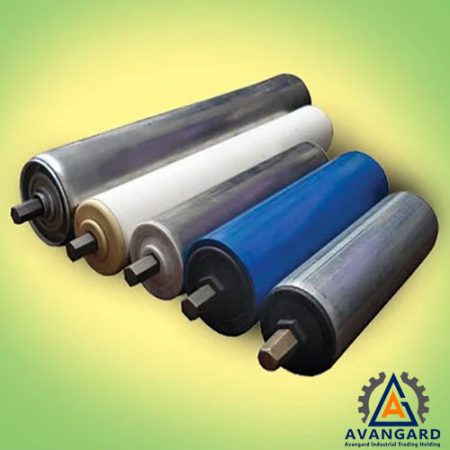

Conveyor Belt Roller

Conveyor belt rollers are one of the main and most important pieces of equipment used in factories and manufacturing companies. Rollers are similar to a free-rotating circular weight that moves around an axis, and usually one of the most important points regarding the purchase of conveyor belt rollers is paying attention to their dimensions and size. The rollers are placed on the conveyor belt and, with their rotary motion, create a flat and rotating space. It should be noted that rollers are produced and supplied by Avangard in various dimensions and diameters according to various industrial and service needs.

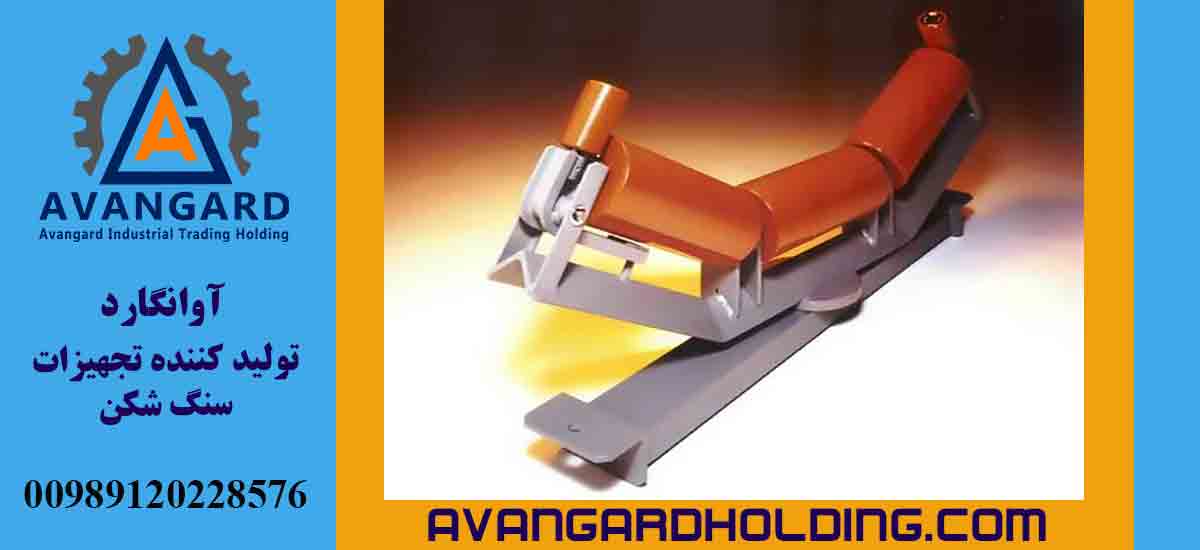

Conveyor Belt Roller Base

The conveyor belt roller base is one of the key components in conveyor belt systems that is responsible for holding the rollers. As its name suggests, this part plays an important role in supporting the rollers. Considering the variety of conveyor belts and their different types, the way the rollers are placed on the roller base can be different.

The conveyor belt roller base is usually designed with two holes in the body so that it can be bolted to the conveyor belt body. These bases are made in the shape of a bracket and are produced in various sizes, according to the dimensions of the rollers. The most common dimensions of conveyor belt roller bases include 60, 80, and 100 cm.

Conveyor Canvas Belt

Conveyor canvas belts, also known as elevator conveyor belts, have attracted much attention due to their wide application in various industries. These belts are usually purchased in large volumes by manufacturers and industrial managers.

Canvas belts are made by combining layers of rubber and canvas, and the number of layers varies based on the width and thickness of the belt. Unlike rubber belts, in this type of belt, the outer and inner layers are made of canvas, and rubber strips are located in the middle layers. After crushing, the minerals are directed to the screen by means of belts and conveyor belts.

Canvas belts are connected to metal or plastic buckets by special fasteners. This feature increases their resistance to indirect heat as well as their smoother movement.

Conveyor Sprocket Gear

Conveyor sprocket gears are usually made of high-quality steel or steel alloys and are cast. The choice of this material is due to important features such as high strength, resistance to pressure and abrasion, precision in manufacturing, and the ability to withstand high forces.

For manufacturing conveyor belt sprocket gears, steel alloys such as CK60 steel (1.1221) or Mo40 steel (AISI 4040) and other alloy steels are often used. These alloys are able to withstand high pressures and forces due to their favorable mechanical properties.

Conveyor or Belt Conveyor Chain

Conveyor or belt conveyor chains are key components in industries and manufacturing that are used to transfer power from the drive section to move materials and goods in a production or processing unit. These chains are made of strong, high-pressure-resistant materials and are usually used in a concentrated or dispersed manner in production systems and machines.

Fixed and Moving Conveyor Rollers

Conveyor rollers are considered one of the important and vital components of conveyors or conveyor belts, which play a key role in moving materials using belts. Conveyor rollers are used to maintain stability, prevent excessive friction, and ensure reliable material transfer along the length of the conveyor belt. They are traditionally available in two types: fixed conveyor rollers and moving conveyor rollers in the types of adjustable rollers, middle rollers, and transfer (drive) rollers for conveyors or conveyor belts at Avangard Company.

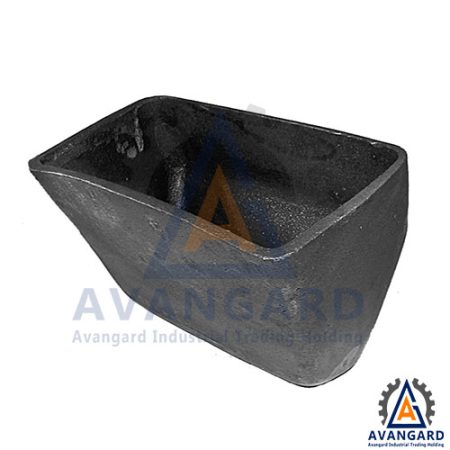

Elevator Buckets

Elevator buckets are key components in elevator (conveyor) or belt and chain lift systems that are used for vertical transport and transfer of various types of materials such as bulk, powder, and granular materials alongside conveyor belts.

These buckets, which are shaped like special containers or buckets, are installed around the elevator belt or chain. Their job is to collect materials from the feed hopper, transport them upwards, and finally empty the contents at the end of the path. Buckets are usually made of metal or plastic and, due to their vital role in the proper functioning of the elevator, require periodic repair and replacement.

Conveyor Clamp

The conveyor clamp is a type of threaded rod with two ends that is bent in the middle in the shape of a U. The term "clamp" comes from the Turkish language and means "bridge" and resembles the letter "U". This piece is also known as a "U-bolt" and "stirrup bolt."

The conveyor clamp, or conveyor belt clamp, sometimes also called an elevator clamp, is one of the widely used components in conveyor belt systems that is widely used in various industries, including the mining industry. This piece acts as an effective fastener and is used to stabilize and hold the components of the conveyor belt in the appropriate places and provide the necessary strength in material transfer systems. The proper design and use of the conveyor belt clamp can have a significant impact on the performance and lifespan of the conveyor belt system.

Conveyor Belt Rubber

Conveyor belt rubber, also known as conveyor belt, is an essential part of the transmission system in conveyor belt machines. These belts can be made of different materials such as chain, PVC, and canvas, and the choice of material depends on the specific conditions of the factory and the application of the conveyor belt.

In the mining and sand and gravel industries, rubber is commonly used due to its high flexibility and resistance to wear and impact. Conveyor belt rubber belts can be divided into two types: simple and treaded; the simple type is suitable for smooth surfaces, and the treaded type is suitable for sloping and angled surfaces.

Key features of rubber belts include quick washability, effective water drainage, and the ability to replace damaged or defective parts. These rubber belts are offered by Avangard Company in widths of 60, 80, 100, and 120 cm. For free consultation on purchasing and price inquiries, you can contact the sales consultants of Avangard Company.

Conveyor Belt Fasteners

Conveyor belt fasteners in various types, including two-bolt, single-bolt, hinge fasteners, needle fasteners, and claw fasteners, or so-called single-bolt claw conveyor belt fasteners and two-bolt claw conveyor belt fasteners, for connecting thick conveyor belts with bolts and nuts, are offered by Avangard Company with high build quality and reasonable prices. These fasteners are made of iron and have high resistance to tension, pressure, and abrasion.

Conveyor belt fasteners are used to connect belts in conveyors where permanent connection by melting and gluing methods is not possible. Since the belt is one of the vital components in a conveyor or conveyor belt and is very important due to its high price, special care must be taken in its design and selection. For this reason, conveyor belt fasteners are also of great importance. The working method is that after selecting and designing the conveyor belts, their two ends are connected to each other, and conveyor belt fasteners are used for this connection.

Conveyor Belt Vulcanizing Glue

Conveyor belt vulcanizing glue is a type of specialized and industrial glue that is used to connect, repair, and mend conveyor belts. This glue, by creating a strong and flexible bond between the two ends of the belt or at damaged points, increases the belt's resistance and durability against operational stresses and pressures. The use of vulcanizing glue is especially important in cases where it is not possible to use fasteners or mechanical connections, or when there is a need for a permanent connection without changing the surface of the belt. These glues are usually used in conditions where the conveyor belt is working under heavy loads or in harsh environments to prevent sudden breakdowns and production stoppages.

Conveyor Electric Motor

A conveyor electric motor is an electric motor that is used to move conveyor belts in material handling systems. These motors are connected directly or through a gearbox to the conveyor and provide the necessary force to move materials on the conveyor belt. Choosing the right electric motor according to the carrying capacity, required speed, and environmental conditions has a great impact on the performance and efficiency of the conveyor system.

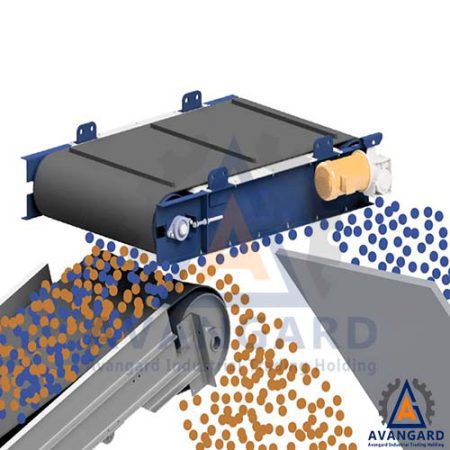

Conveyor Belt Magnet

The conveyor belt magnet is one of the key pieces of equipment in the crushing systems of sand and gravel mines. This device is used to separate unwanted metal parts, such as iron pieces, from the materials passing on the conveyor belt. By using a conveyor magnet, the risk of damage to crushing machines and the reduction of system efficiency is significantly reduced. In addition to increasing the useful life of equipment, this device also helps to improve the overall performance of the system.

Conveyor belt magnets are produced in various sizes and powers, which are selected based on the width of the conveyor belt and the specific needs of each system. At Avangard Company, different types of conveyor belt magnets are available that can be used for various applications in mining crushing systems.

Sale of Conveyor and Elevator Parts

Avangard Company, by offering a complete set of conveyor and elevator parts, enables you, esteemed industrialists, to meet all your needs in the field of maintenance and optimization of this equipment. Our products include various parts with high quality and reasonable prices that are suitable for industrial and mining material transfer systems. To purchase and receive more information, contact the Avangard sales unit to benefit from our services.

Purchase of Conveyor and Elevator Parts

To purchase high-quality conveyor and elevator parts at a reasonable price, Avangard Company is the best option for meeting your industrial and crusher spare parts needs. We offer all kinds of parts needed for material transfer systems according to the latest standards and with a guarantee of quality. For consultation and purchase, contact the Avangard sales unit and enjoy a reliable purchase experience.

Price of Conveyor and Elevator Parts

The price of conveyor and elevator parts varies depending on different brands and can vary according to your needs. For more detailed information and free consultation, contact Avangard sales experts.

We apologize that all prices are currently being updated. Please contact Avangard's sales department to inquire about purchase prices.

| Row | Description | Price |

| 1 | Price of Conveyor Belt Roller | Contact |

| 2 | Price of Conveyor Belt Roller Base | Contact |

| 3 | Price of Conveyor Canvas Belt | Contact |

| 4 | Price of Conveyor Sprocket Gear | Contact |

| 5 | Price of Conveyor or Belt Conveyor Chain | Contact |

| 6 | Price of Conveyor Rollers | Contact |

| 7 | Price of Conveyor Drums | Contact |

| 8 | Price of Elevator Bucket | Contact |

| 9 | Price of Conveyor Clamp | Contact |

| 10 | Price of Conveyor Belt Rubber | Contact |

| 11 | Price of Conveyor Belt Fastener | Contact |

| 12 | Price of Conveyor Belt Vulcanizing Glue | Contact |

| 13 | Price of Conveyor Electric Motor | Contact |

| 14 | Price of Conveyor Belt Magnet | Contact |

| 15 | Price of Elevator Belt | Contact |

| 16 | Price of Conveyor Belt | Contact |

| 17 | Price of Conveyor Roller | Contact |

فارسی

فارسی  Arabic

Arabic