[rank_math_breadcrumb]

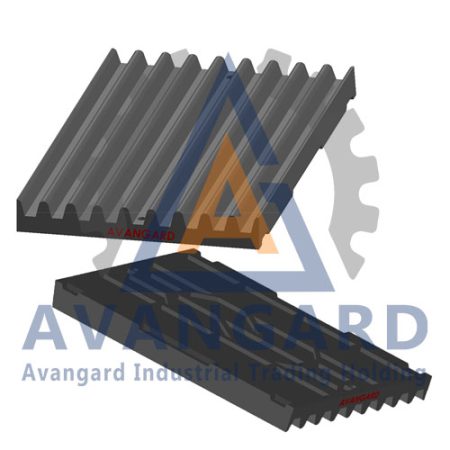

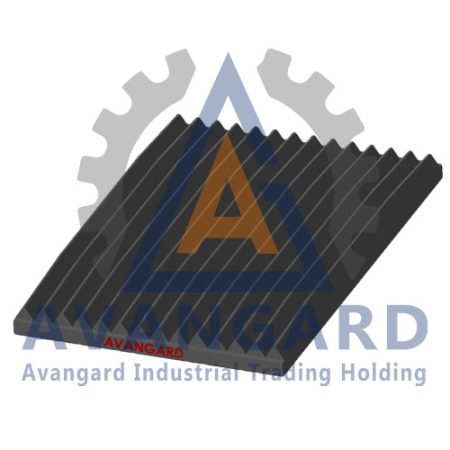

Jaw Plate

The jaw plate is one of the components of the jaw crusher, which plays a role in the crushing of materials and rocks. This plate is made from high-quality manganese steel to offer greater resistance and longevity against the pressure and abrasion caused by the crushing process. The jaw plate in the jaw crusher acts as the main part of the crusher during material crushing and breaks rocks into smaller sizes upon impact. This part can be purchased and replaced separately to maintain the crusher’s durability and efficiency. When purchasing a jaw plate, it is important to choose high-quality materials and precisely execute technical specifications. Jaw plates are divided into two types: movable jaw plate and fixed jaw plate.

Jaw Plate Sales

Avangard Company, with a long-standing history in international production and experience in design, casting, and sales of jaw plates, offers high-quality manganese and molybdenum manganese jaw plates at competitive prices in Iran and the Middle East. To order, purchase, and inquire about jaw plate prices or to get information about crusher parts, please contact our colleagues at Avant-garde Company.

Related article: Casting Services

Jaw Plate Price

The price of jaw plate parts varies based on the percentage range of alloying elements desired by the customer and the fluctuations in alloy element prices. For ordering your desired material for the production and casting of fixed and movable jaw plate parts, contact our experts at Avant-garde Company for jaw crusher prices and toggle plate prices.

Price List of Jaw Crusher Jaw Plates

| No. | Description | Price |

|---|---|---|

| 1 | Price of Fixed Jaw Plate 125*30 | Contact Us |

| 2 | Price of Movable Jaw Plate 125*30 | Contact Us |

| 3 | Price of Fixed Jaw Plate 100*63 | Contact Us |

| 4 | Price of Movable Jaw Plate 100*63 | Contact Us |

| 5 | Price of Fixed Jaw Plate 80*55 | Contact Us |

| 6 | Price of Movable Jaw Plate 80*55 | Contact Us |

| 7 | Price of Short Fixed Jaw Plate 40*90 | Contact Us |

| 8 | Price of Short Movable Jaw Plate 40*90 | Contact Us |

| 9 | Price of Long Fixed Jaw Plate 90*40 | Contact Us |

| 10 | Price of Long Movable Jaw Plate 90*40 | Contact Us |

| 11 | Price of Fixed Jaw Plate 45*65 | Contact Us |

| 12 | Price of Movable Jaw Plate 45*65 | Contact Us |

| 13 | Price of Movable Jaw Plate 100*80 | Contact Us |

| 14 | Price of Fixed Jaw Plate 100*80 | Contact Us |

| 15 | Price of Long Toggle Fixed Jaw Plate 80*100 | Contact Us |

| 16 | Price of Long Toggle Movable Jaw Plate 80*100 | Contact Us |

| 17 | Price of Fixed Laboratory Small Jaw Plate | Contact Us |

| 18 | Price of Movable Laboratory Small Jaw Plate | Contact Us |

| 19 | Price of Long Tooth Fixed Jaw Plate 55*80 | Contact Us |

| 20 | Price of Movable Jaw Plate 60*90 | Contact Us |

| 21 | Price of Long Tooth Movable Jaw Plate 55*80 | Contact Us |

| 22 | Price of Fixed Jaw Plate 60*90 | Contact Us |

| 23 | Price of Movable Jaw Plate 110*90 | Contact Us |

| 24 | Price of Fixed Jaw Plate 110*90 | Contact Us |

| 25 | Price of Movable Jaw Plate 100*120 | Contact Us |

| 26 | Price of Fixed Jaw Plate 100*120 | Contact Us |

| 27 | Price of Goodwin Movable Jaw Plate 90*30 | Contact Us |

| 28 | Price of Goodwin Fixed Jaw Plate 90*30 | Contact Us |

Technical Specifications of Jaw Plate

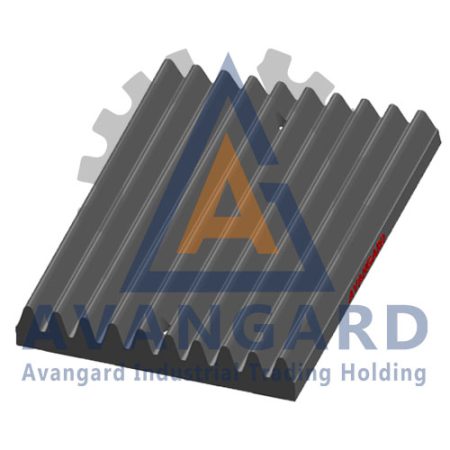

Jaw plates can also crush stones larger than 130 centimeters. This is done through the compressive force between the two jaw plates. These plates have an angle between 26 and 27 degrees, which directly affects the output material size by adjusting the jaw crusher's opening. Usually, the material of these two plates is manganese steel for good endurance. The capacity of the jaw crusher's jaw plate reaches up to 6000 tons per hour, meeting the needs of many industries and large mines.

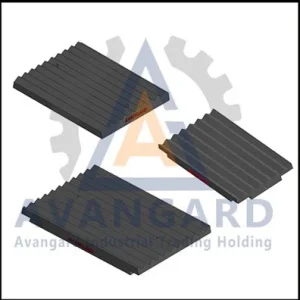

Jaw plates are crucial components of a jaw crusher and are divided into two types: fixed and movable. The fixed jaw plate is used in the initial stage of rock crushing. This type of jaw plate is positioned opposite the movable jaw plate.

The movable jaw plate is another component of the jaw crusher that works alongside the fixed jaw plate to crush rocks. The movable jaw plate moves towards the fixed jaw plate using electromechanical force, breaking the rocks.

Technical specifications for jaw plates may vary depending on the model and manufacturer of the jaw crusher, but generally, the key specifications include:

1. Material Composition

Jaw plates are usually made from manganese steel and molybdenum manganese steel. In some cases, they are also produced from Ni-Hard cast iron based on customer requests.

2. Dimensions

The dimensions of the jaw plate must be precisely determined to align with other components such as the Jaw Crusher Toggle Plate.

3. Weight

The weight of the jaw plate needs to be balanced with other crusher parts to prevent undesirable forces and pressures.

4. Structure and Design

The structure of the jaw plate should allow easy and quick replacement, and for improved crushing efficiency, longer lifespan, and controlled output sizes, the appropriate teeth should be designed and produced for the jaw plate.

Related article: Jaw Shim of Crusher

Types of Jaw Plates

Jaw plates, used in jaw crushers, are employed in the initial crushing phase of materials and consist of two types: fixed and movable. The fixed jaw plate is positioned in a fixed location, and input materials are crushed by being placed between these two jaws under pressure and crushing effect. This working arrangement utilizes the interaction between the movable and fixed jaw plates to crush materials and create crushed aggregates.

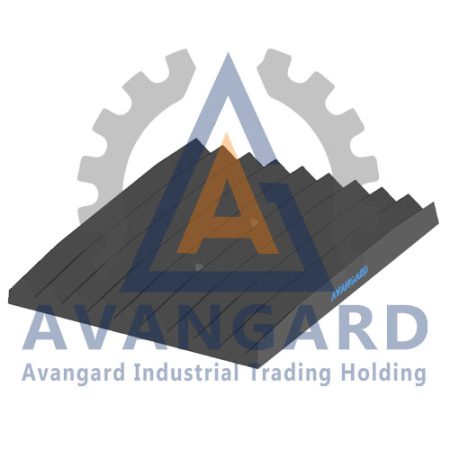

1. Fixed Jaw Plate

The fixed jaw plate is a component of the jaw crusher used in the initial stage of the crushing process. This plate is a fixed part of the crusher structure, playing a key role in crushing the input materials as it is held in place.

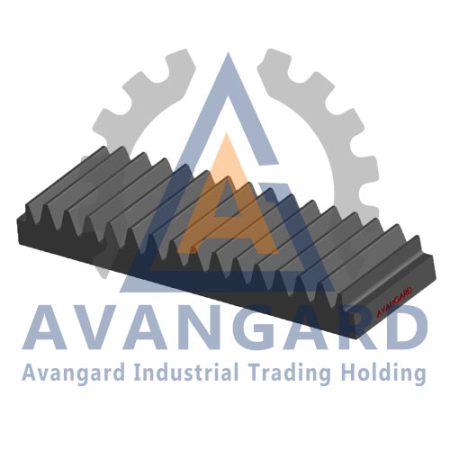

2. Movable Jaw Plate

The movable jaw plate plays a crucial role in the operation of the jaw crusher and is important in material crushing. The alternating movement of this jaw plate creates a crushing effect on the materials, facilitating the crushing process. It is a movable part of the crusher, moving vertically up and down.

The main function of the movable jaw plate in the jaw crusher is to create pressure and a crushing effect on the input materials. The input materials are placed between the movable and fixed jaw plates (which is stationary) and are crushed under the pressure and crushing effect of these jaw plates. The crushed materials are then moved down to the outlet and proceed to subsequent processing stages.

فارسی

فارسی  Arabic

Arabic