[rank_math_breadcrumb]

Jaw Crusher Parts

Jaw crusher parts play a vital role in crushing stones, and entering the world of jaw crusher industry brings you to a realm of parts such as movable Jaw and fixed Jaw, which are the primary components in jaw crusher machines. These machines are tools used for crushing rocks and minerals. Jaw crusher machine in mining is one of the types of crusher machines used as the primary crusher. Due to its open mouth, which is the gap between two jaws at the upper part, it performs efficiently for mountain and river stones. Its function is such that in the initial stage (primary crushing), large pieces produced by blasting or extraction with natural dimensions are used to reduce the size of ores and stones to various sizes suitable for transportation by common transport methods (like conveyors) and transfer to the next stage (secondary crushing).

Purchasing Jaw Crusher Parts

When purchasing jaw crusher parts, it is important to pay attention to their authenticity and quality. Given the market diversity, choosing high-quality parts at reasonable prices is crucial. Are you looking for a movable jaw with long life and durability? Or a fixed jaw that crushes materials with power and stability? In any case, take advantage of Avant-garde as one of the market leaders in jaw crusher spare parts. By relying on modern technology and the use of quality materials, we offer parts that give you the ability to crush minerals to desired sizes. Contact us to benefit from the latest technologies and the best parts for your jaw crusher. Your trust is our investment. Avant-garde is the best source for ordering casting high-quality and reasonably priced jaw crusher parts. We offer parts with long life and high efficiency, including movable and fixed jaws, with the latest technology and quality materials, ensuring your purchase is secure and satisfactory. Order now and experience the best with us.

Jaw Crusher Parts Pricing

Avant-garde Holding is one of the best options for purchasing the highest quality and most economical crusher parts. Avant-garde as a manufacturer of various sizes and dimensions of jaw crusher parts is ready to receive orders, design, and cast your desired parts with the highest quality tailored to your needs. Avant-garde, a reliable source for pricing jaw crusher parts. Prices are being updated, for more details and jaw crusher pricing inquiry, contact us.

Jaw Crusher Component Price List

| No. | Description | Price |

| 1 | Fixed Jaw Price for Jaw Crusher | Contact us |

| 2 | Movable Jaw Price for Jaw Crusher | Contact us |

| 3 | Jaw Holder Price for Jaw Crusher | Contact us |

| 4 | Jaw Bearing Price for Jaw Crusher | Contact us |

| 5 | Toggle Jaw Price for Jaw Crusher | Contact us |

| 6 | Movable Jaw Holder Price for Jaw Crusher | Contact us |

| 7 | Fixed Jaw Holder Price for Jaw Crusher | Contact us |

| 8 | Jaw Back Price for Jaw Crusher | Contact us |

| 9 | Short Channel Price for Jaw Crusher | Contact us |

| 10 | Long Channel Jaw Price for Jaw Crusher | Contact us |

| 11 | Eccentric Shaft Price for Jaw | Contact us |

| 12 | Electric Motor Price for Jaw Crusher | Contact us |

| 13 | Bearing Price for Jaw Crusher | Contact us |

| 14 | Side Holder Price for Jaw Crusher | Contact us |

| 15 | Cover and Parts Price for Jaw Crusher | Contact us |

Related Article: "Impact Crusher Parts"

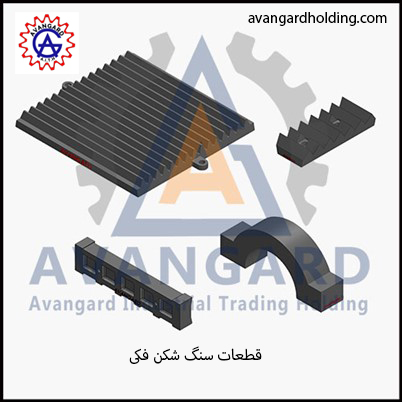

Types of Jaw Crusher Parts

In a jaw crusher, the size of the jaw is determined by the size and dimensions of the rectangular opening at the top input. The movable jaw is held back by a strong spring. This ensures the crusher has the necessary safety against very hard parts (like metal pieces). In these machines, the motion of the jaws is created by various methods with the main objective being to generate maximum force in the gap between the two jaws to crush the materials. Jaw crusher accessories include fixed jaw plate, movable jaw plate, fixed jaw strap, movable jaw strap, side plate, bearing, bush, channel, eccentric shaft, electric motor, cover, etc. We will briefly explain the main parts of a jaw crusher.

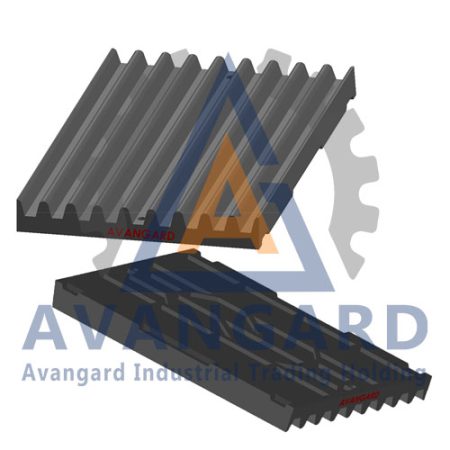

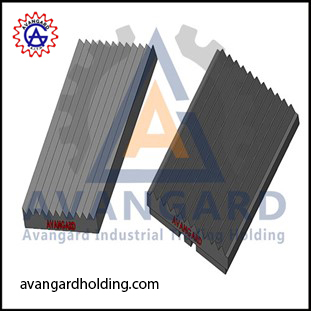

Jaw Plate of Jaw Crusher

" jaw plates" is an essential part installed in pairs in the jaw crusher. These plates include both the fixed jaw plate and the movable jaw plate.

1-Fixed Jaw Plate

This plate is fixed in the crusher and attached to the body of the crusher. It is usually made of high-quality Hadfield or manganese steel to provide adequate resistance and strength for crushing heavy and hard materials.

2-Movable Jaw Plate

This plate moves within the crusher and causes the primary crushing of the incoming materials. It is also usually made from manganese or manganese molybdenum steel, possessing suitable strength and hardness to perform the crushing operation. Different jaw plate models are designed based on the dimensions and types of materials to be crushed, and for different application conditions, they are offered by Avant-garde Company with excellent quality and reasonable price to esteemed industry professionals.

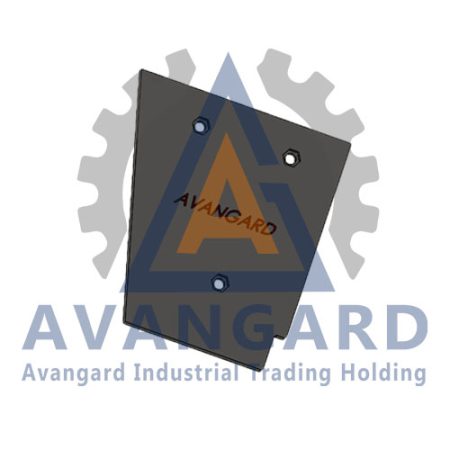

Jaw Strap of Jaw Crusher

"Jaw Strap" is divided into two main categories: the fixed jaw strap and the movable jaw strap of the jaw crusher. These two types of straps are made from manganese or manganese molybdenum steel, designed to hold and secure the jaw plates of the jaw crusher.

1-Fixed Jaw Strap

This strap is responsible for holding and securing the fixed jaw plate of the jaw crusher to the body and toggle through bolts and nuts.

2-Movable Jaw Strap

The movable jaw strap holds and secures the movable jaw plate of the jaw crusher to the body and toggle through bolts and nuts. The dimensions and size of each jaw strap depend on the type and dimensions of the jaw crusher. All models of jaw straps for jaw crushers are designed, manufactured, and cast at Avant-garde Company. For consultation, purchase, and price inquiries, you can contact Avant-garde’s sales experts.

Related Article: "Hydrocone Crusher Parts"

Types of Jaw Crushers

Jaw crushers are used to crush and fragment stones, and each type of stone, depending on its characteristics and reactions to hardness and other factors, performs differently in the crushing process. The device you choose varies based on the type of stones. In the classification of jaw crushers, there are two categories: single-toggle and double-toggle:

1- Single Toggle

In this type of jaw crusher, the jaws move with a single toggle to move up and down, front and back, applying less pressure on the stones. This type has a smaller feed opening and is suitable for hard stones.

2- Double Toggle

In this type of jaw crusher, two jaws move back and forth synchronously with a pair of toggles. This machine has a larger feed opening compared to the single-toggle type and applies higher pressure on the stones, thus it is used for very hard and hard stones.

Related Article: "Casting Services"

Specifications of various jaw crusher machines:

| No. | Model (Cm) | Max Input Size (mm) | Output Size (mm) | Production Capacity (t/h) | Motor Power (Kw) | Machine Weight (ton) | Dimensions (L*W*H) (mm) |

| 1 | 30*20 | 180 | 20-80 | 15-20 | 30 | 2 | 1010*1070*1100 |

| 2 | 50*30 | 280 | 30-90 | 30-50 | 37 | 4.5 | 1040*1250*1070 |

| 3 | 60*40 | 380 | 40-100 | 40-60 | 45 | 6.5 | 1390*1520*1550 |

| 4 | 65*45 | 430 | 40-100 | 40-60 | 45 | 7 | 1570*1540*1710 |

| 5 | 55*80 | 520 | 50-120 | 80-120 | 55 | 11 | 1800*1850*1950 |

| 6 | 90*30 | 280 | 30-100 | 60-80 | 55 | 7.5 | 1650*2070*1640 |

| 7 | 90*50 | 480 | 50-120 | 90-130 | 75 | 12 | 1900*2200*1930 |

| 8 | 90*60 | 580 | 90-180 | 150-200 | 90 | 16 | 2520*2300*2410 |

| 9 | 90*70 | 680 | 70-150 | 150-200 | 90 | 18 | 2440*2280*2400 |

| 10 | 30*125 | 280 | 20-100 | 80-100 | 55 | 10 | 1750*2325*1800 |

| 11 | 80*100 | 780 | 90-180 | 150-200 | 90 | 16 | 2100*2280*2360 |

| 12 | 90*110 | 880 | 90-200 | 250-300 | 90-110 | 24 | 2250*2550*2950 |

| 13 | 90*40 | 380 | 40-100 | 70-130 | 55 | 11 | 1112*2190*1700 |

| 14 | 63*100 | 600 | 63-200 | 75-160 | 75 | 16 | 1610*2300*2100 |

| 15 | 100*120 | 950 | 150-300 | 275-500 | 120-140 | 43 | 2585*2725*2715 |

| 16 | 110*120 | 1050 | 125*275 | 300*600 | 150-200 | 45 | 2600*2500*3000 |

| 17 | 107*140 | 1000 | 200-350 | 500-600 | 200 | 52 | 440*3000*3800 |

| 18 | 130*150 | 1250 | 200-400 | 400-1000 | 200 | 70 | 3050*2900*4500 |

| 19 | 30*150 | 250 | 35-100 | 80-100 | 75 | 12 | |

| 20 | 40*160 | 350 | 40-100 | 100-130 | 75 | 16 |

فارسی

فارسی  Arabic

Arabic