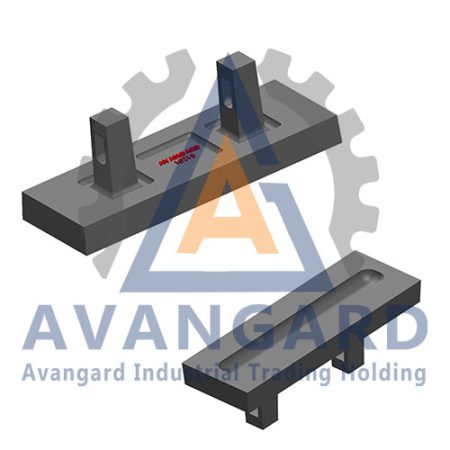

Parker Hammer 103

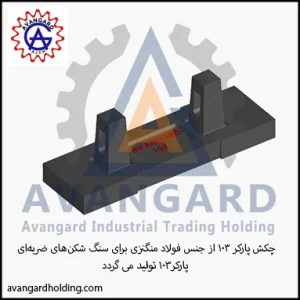

Parker Hammer 103 is one of the Parker Crusher parts and a subset of the impact crusher. This hammer is made of manganese steel with a carbon range of 1.1-1.3% according to DIN1.3401 standard. Due to its wear and impact resistance properties and the presence of the high-hardness martensitic phase during operation, it is ideal for use in harsh conditions and mineral crushing processes.

These tools have high hardness to break rocks more quickly and efficiently. Furthermore, precise machining on other main parts of the Parker crusher has improved their lifespan. However, due to frequent use, these tools might become damaged or worn out over time. Therefore, repairing and enhancing Parker Hammer 103 can increase their useful life when parts are damaged. Considering that every eight Parker Hammer 103s are considered one set, you can purchase Parker Hammer 103 and inquire about the price of other related parts by contacting the sales department of Avangard Holding.

What is Parker Hammer 103?

Parker Hammer 103 is an essential part of Parker impact crushers. In Parker 104 cubits, the rotor is manufactured in two pieces, and hammers are mounted on the arms using hammer pins. In contrast, the rotor for Parker 103 cubits is three pieces, and hammers are zigzagged on the arms between each piece using hammer pins. It is worth mentioning that hammers are the most costly and consumable part of cubits; therefore, it is crucial to make the most use of them. In Parker Hammers 104, 103, and 3, by changing the position and reversing the hammer, both edges can be used. To purchase Parker Hammer 103, manganese and manganese-molybdenum types, or buy crusher parts at an affordable price, contact our experts at Avangard Production Holding.

Related article: Foundry Services

Purchase Parker Hammer 103

Purchasing Parker Hammer 103 from Avangard is simple through interaction with technical experts. Avangard, with over two decades of experience in producing, designing, and selling Parker Hammer 103 in manganese and manganese-molybdenum types, offers quality services at competitive prices. The main materials used in making these hammers provide more compatibility and better performance. Our team is ready to offer you services with superior abilities. For more information and purchase, contact our team at Avangard.

Price of Parker Hammer 103

The price of Parker Hammer 103 varies depending on the range of alloying elements desired by the customer and fluctuating prices of alloy elements. To order your desired alloy for producing Parker Hammer 103, contact our experts at Avangard. With over two decades of production experience and a high academic level team of mechanical, metallurgical, mining, and electrical engineers, all of whom graduated from top universities both domestically and internationally, Avangard assures respectful mine owners and industrialists that, if necessary, by making changes in the alloy and adding elements like manganese, molybdenum, titanium, nickel, and other useful elements, and altering the manufacturing method and heat treatment cycle, potential problems of respectful mine owners will be resolved, enhancing their resistance to wear significantly and therefore increasing efficiency. We are prepared to offer you quality services and competitive prices in producing, designing, and selling Parker Hammer 103.

| Row | Description | Price |

|---|---|---|

| 1 | Parker Hammer 103 | Contact us |

| 2 | Parker Hammer 103 Round Edge | Contact us |

| 3 | Parker Hammer 103 Hexagonal | Contact us |

| 4 | Parker Cover 10 | Contact us |

| 5 | Parker Rotor Right | Contact us |

| 6 | Parker Rotor Left | Contact us |

| 7 | Parker Rotor Middle | Contact us |

| 8 | Parker Arm 103 Right | Contact us |

| 9 | Price of Parker Arm 103 Left | Contact us |

| 10 | Price of Parker Shoe Right | Contact us |

| 11 | Price of Parker Shoe Left | Contact us |

Material of Parker Hammer 103

The material of Parker hammers is manganese steel with Din 1.3401 standard, and Avangard adjusts the alloy and adds elements like molybdenum to increase the hammer's lifespan according to the mine type. Notably, six Parker hammers are used in one set, eight Parker Hammer 103s in one set, and four Parker Hammer 3s in one set. Cobits (Impact Crushers) are among the most common devices in crushing lines, typically used as secondary crushers.

Related Article: Parker Hammer 3 In cobits, there is a mobile part called a rotor, on which is fixed a number of hammers made of anti-wear alloys, depending on the cobit model. The incoming load (stones and minerals) is thrown towards the inner walls of the device, including side panels, anvils, and covers, installed at various angles, each made of anti-wear alloy, to create crushing. Additionally, to protect the rotor's vulnerable parts, rotor guards or rotor shoes are used.

Sale of Parker Hammer 103

Considering the various needs of mines for Parker Hammer 103, Avangard with over two decades of experience in casting production and selling impact crusher parts, offers extensive services to its customers. These services include the sale of Parker Hammer 103. Avangard has the ability to design and manufacture a new Parker Hammer 103 by changing its length, width, thickness, and according to desired weight, to improve its efficiency and meet customer needs. This gives customers confidence that Parker Hammer 103s purchased from Avangard are precisely aligned with their needs and will provide the best performance. Therefore, if you are looking to purchase high-quality Parker Hammer 103 tailored to your needs, contact us. The Avangard Holding team is ready to help and offer reliable quality services.

Production Rate of Parker Crusher 103

Depending on the input feed rate of the Parker crusher and the type of device, between 40 to 200 tons per hour are crushed. Also, the product of the Parker crusher is cubic-shaped and highly durable, suitable for construction, road construction, etc. It should be noted that Parker Hammer 103 is made of Hadfield or manganese casting steel with DIN 1.3401 standard, which is wear-resistant and impact-resistant.

Quality of Parker Crusher 103

The stone produced by this crusher is highly symmetrical and cubic, providing high resistance in construction and road-building uses, thus attracting more customers. However, maintaining this crusher is costly, and its consumable parts need to be replaced faster than other crusher models. Parker Hammer 103, made of manganese and manganese-molybdenum with top quality produced at Avangard, is considered one of the most consumable parts in sand and gravel mines.

Types of Parker Hammer 103

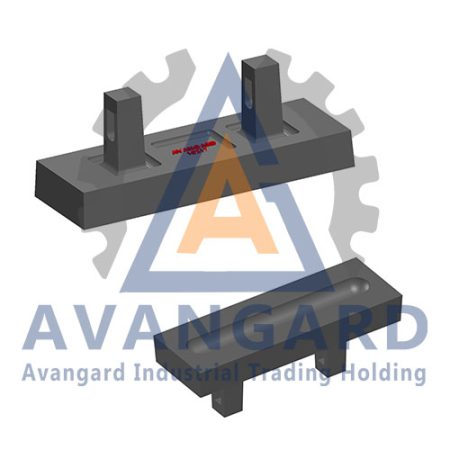

The diversity of Parker Hammer 103 relies on the crusher dimensions, type of stones and materials being crushed, and the customer's desired weight. Each type of hammer might be optimized for certain conditions and applications. Each Parker 103 device has 8 Parker Hammer 103 pieces that are zigzagged on arms between the three pieces of rotor 103. Some types of Parker Hammer 103 have varying designs, sizes, and weights with high precision and quality. For selecting the best Parker Hammer 103 for specific needs and conditions, it's recommended to consult with a reputable manufacturer or supplier like Avangard, which employs experienced and professional engineers in this field. Parker Hammer 103 is manufactured from manganese steel or Hadfield in the foundry, standardized as DIN 1.3401, providing high resistance to wear and impact. These hammers are available in the international market in different shapes such as flat, round edge, and hexagonal, and Avangard has the capability to design and manufacture various models of Parker Hammer 103.

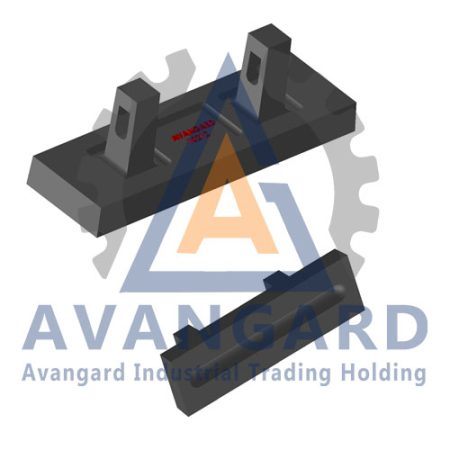

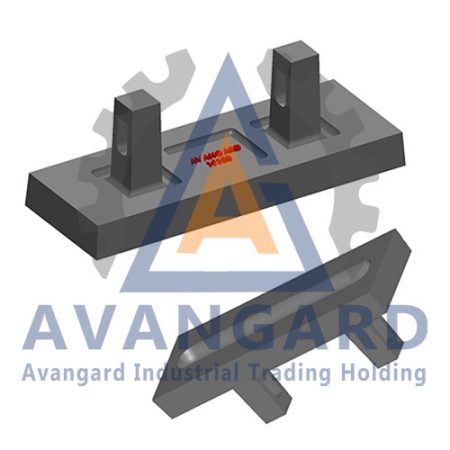

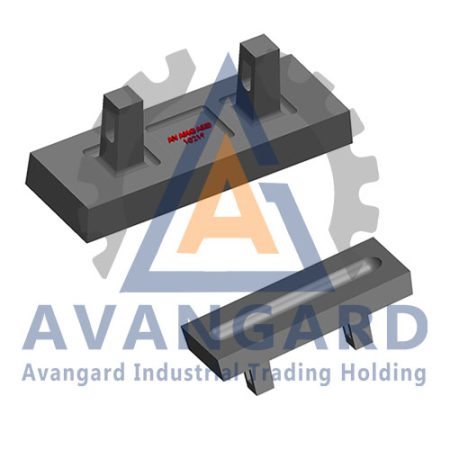

1. Parker 103 Flat

One of the critical components in impact crusher model Parker 103 is Parker Flat Hammer 103. This type of hammer has a rectangular prism shape, with some models having a weight-reducing part beneath it. This design is intended to reduce weight and increase the hammer's efficiency in mineral material crushing processes. The advantages of Parker Flat Hammer 103 include: 1. Rectangular prism design: This type of design is highly effective for delivering strong and efficient impacts in the heavy material crushing process. 2. Under-hammer feature for weight reduction: Improves hammer performance by reducing weight, decreases impact on crusher structures, and is more economically feasible. 3. Flexibility in dimensions and material is a key feature of Parker Flat Hammer 103. These hammers are designed and manufactured to support various dimensions and materials according to customer needs and the type of rocks to be crushed. 4. Efficiency and resistance to wear and impact are notable features of Parker Flat Hammer 103. Using resistant materials like manganese steel and manganese-molybdenum steel in the hammer structure provides high wear and impact resistance.

2. Parker Hammer 103 Round Edge

Parker Hammer 103 Round Edge has rounded longitudinal sides and a standard R based on other specifications. Additionally, a weight-adjusting part is designed underneath for desired weight calibration. This type of Parker Hammer 103 Round Edge, as one of the critical parts in Parker impact crushers, improves performance and efficiency in these machines and can be used in various industries that require mineral crushing.

3. Parker Hammer 103 Hexagonal

Parker Hexagonal Hammer 103 has a special and unique appearance designed and manufactured according to customer demands. This model features a weight-reducing part underneath to reduce weight. This leads to reduced production costs and makes the purchasing process more economically viable.