[rank_math_breadcrumb]

Hydrocone Concave

The Hydrocone Concave is a cone-shaped part made of manganese steel and molybdenum manganese steel, available in raw and machined forms. Its main function is the crushing of input materials and is one of the vital spare parts of the Hydrocone crusher, which is placed inside the top shell and on the Hydrocone mantle. The Hydrocone crusher concave (Concave Hydrocone) encounters the most wear and tear, and its replacement depends on usage duration, input rock type, output rock dimensions, and other factors. After stone extraction and entry into the Hydrocone crusher tank, the crushing process is carried out by the Hydrocone concave and mantle. Avangard produces Hydrocone concaves in various sizes according to customer needs. For inquiries about Hydrocone concave pricing and purchasing with the highest quality and the best performance guarantee, contact the sales experts at Avangard Holding.

Selling Hydrocone Concave

Avangard, with over two decades of experience in selling, producing, designing, and casting various Hydrocone concaves for 36-inch, 45-inch, 48-inch, 54-inch Hydrocone machines, as well as 66-inch and 84-inch SYMONS Hydrocone crushers and Locomo Hydrocone crushers, offers services to esteemed customers in Iran and the Middle East using materials such as manganese and molybdenum manganese steel with the highest quality and best price. To order and purchase Hydrocone concaves, please contact Avangard's technical and sales team. Ensuring superior quality and customer satisfaction is our top priority.

Related Article: Casting Services

Price of Hydrocone Concave

The price of Hydrocone concave varies based on the percentage range of alloy elements desired by the customer and the fluctuations in the prices of these alloy elements. To order the desired alloy for Hydrocone concave production, contact our experts at Avangard.

| Row | Description | Price |

| 1 | Price of Concave 2 Hydrocone | Contact Us |

| 2 | Price of Concave 4 Hydrocone | Contact Us |

| 3 | Price of Concave 5 Hydrocone | Contact Us |

| 4 | Price of Concave 5/6 Hydrocone | Contact Us |

| 5 | Price of Concave 7 Hydrocone | Contact Us |

| 6 | Price of Concave 8 Hydrocone | Contact Us |

| 7 | Price of Locomo Concave | Contact Us |

| 8 | Price of Eibach Concave | Contact Us |

| 9 | Price of Concave H3000 | Contact Us |

| 10 | Price of Concave Brick 13 Inch | Contact Us |

| 11 | Price of Concave Brick 11 Inch | Contact Us |

| 12 | Price of 36 Inch Hydrocone Concave | Contact Us |

| 13 | Price of 45 Inch Hydrocone Concave | Contact Us |

| 14 | Price of 48 Inch Hydrocone Concave | Contact Us |

| 15 | Price of 54 Inch Hydrocone Concave | Contact Us |

| 16 | Price of 66 Inch Hydrocone Concave | Contact Us |

| 17 | Price of 84 Inch Hydrocone Concave | Contact Us |

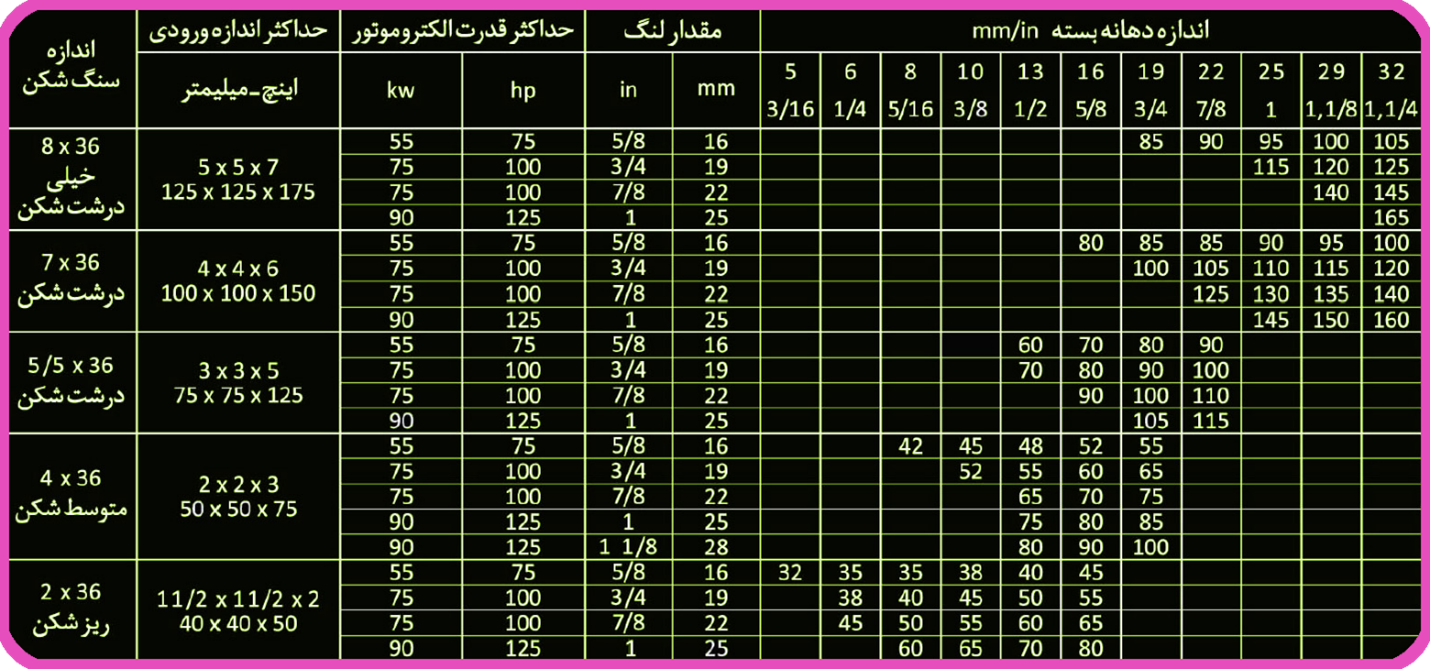

Technical Specifications of Hydrocone Concave

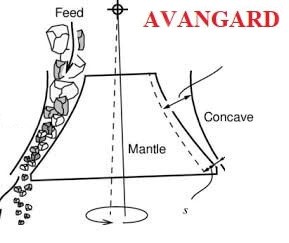

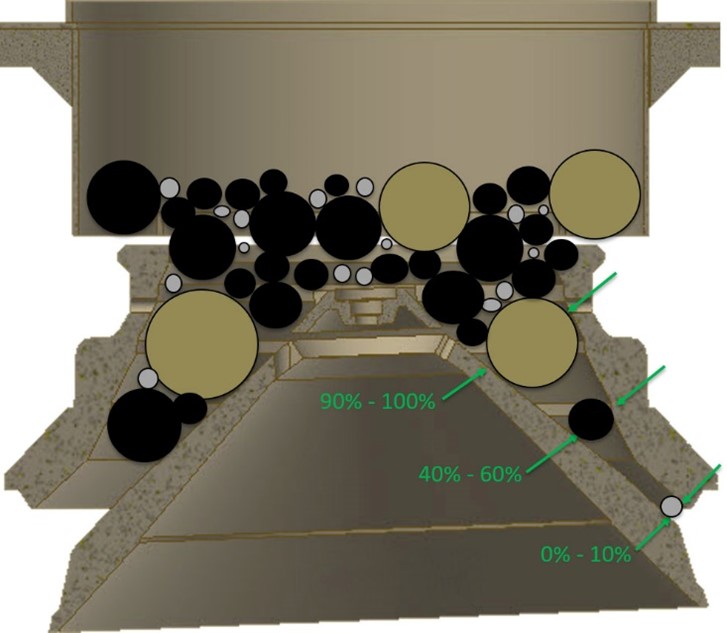

The Hydrocone Concave in Hydrocone crusher parts is placed inside the top shell and above the Hydrocone mantle, while the mantle is located on the Hydrocone head center. When minerals enter the Hydrocone crusher chamber, they are trapped between the mantle and concave. With the rotation of the mantle caused by the eccentric movement of the shaft connected to the head center, the gap between the concave and mantle expands and contracts, crushing the minerals. The size of the crushed stones depends on the distance between the concave and mantle and the reduction degree, which can be adjusted to control the output size of the stones. The Hydrocone concave has a specific angle that creates a V-shaped empty space between the concave and mantle. The angle of the Hydrocone concave is directly related to the performance and crushing speed of the stones; the smaller this angle, the less space for stone entry, the more friction and wear, and the larger the change in output stone size.

Material of Hydrocone Concave

Manganese Steel:

Produced by adding alloying elements such as carbon, silicon, chromium, and manganese to carbon steel, it is used for its high resistance to abrasion and impact, particularly in challenging conditions. This type of steel is used in the production of Hydrocone crusher parts due to its enhanced resistance to wear and impact. The manganese content in its composition usually ranges from 11.5% to 13% and can be increased upon request by the employer.

Manganese Molybdenum Steel:

Produced by adding a small amount of molybdenum to manganese steel. Molybdenum is added to improve resistance against corrosion, abrasion, and fatigue. Therefore, manganese molybdenum steel is used, especially in environments with more corrosion and abrasion. The molybdenum content in this type of steel typically ranges from 0.3% to 0.5%, and can be increased up to 1% upon customer request. It is noteworthy that with increased molybdenum, the percentage of manganese must also increase, which Avangard's technical engineers achieve by using an appropriate and accurate chemical melting mix, yielding Hydrocone concaves with the best performance.

Types of Hydrocone Concave

When selecting the appropriate concave for the Hydrocone crusher, several factors must be considered. For example, the type and model of crusher parts like fine crusher, coarse crusher, or intermediate crusher in various models (e.g., 36-2, 36-4, etc.) must be considered. Furthermore, the dimensions and hardness of the input rocks, operational conditions like temperature, humidity, speed, and pressure, and the size of the top shell and mantle are also significant. Additionally, the concave's resistance and quality can be influential. These factors all impact the optimal selection of a concave for the Hydrocone crusher and require precise and intelligent analysis. Concaves are categorized based on their dimensions, angles, and output material size, which, along with mantle and top shell types, are known as fine crusher, coarse crusher, or intermediate crusher.

| Model | Mantle | Concave | Top Shell | Max Input Mouth Size (mm) | Closed Mouth (mm) | Total Production (ton/hour) | Fine Grain (ton/hour) |

| 2-36 | 2 | 2 | 4 | 50 | 8-10-13-19 | 60-65-70-80 | 42-45-49-56 |

| 4-36 | 4 | 4 | 4 | 100 | 13-16-19 | 80-90-100 | 52-58-65 |

| 5.5-36 | 4 | 5.5 | 5.5 | 140 | 19-22 | 105-115 | 68-69 |

| 7-36 | 4 | 7 | 7 | 175 | 25-29-32 | 145-150-160 | 87-90-96 |

| 8-36 | 4 | 8 | 8 | 200 | 32 | 165 | 82 |

1. Concave 2 Hydrocone

Concave 2 Hydrocone has 6 arms and weighs approximately 520 kg, manufactured in both manganese steel and molybdenum manganese steel, available in raw and machined forms.

2. Concave 4 Hydrocone

Concave 4 Hydrocone has 6 arms and weighs approximately 450 kg, available in both manganese steel and molybdenum manganese steel, in raw and machined forms.

3. Concave 5 Hydrocone

Concave 5 Hydrocone has 6 arms and weighs around 478 kg, available in both manganese steel and molybdenum manganese steel, in raw and machined forms.

4. Concave 6/5 Hydrocone

Concave 6.5 Hydrocone has 6 arms and weighs approximately 580 kg and is manufactured in both manganese steel and molybdenum manganese steel, in raw and machined forms.

5. Concave 7 Hydrocone

Concave 7 Hydrocone has 4 arms and weighs about 496 kg and is available in both manganese steel and molybdenum manganese steel, in raw and machined forms.

6. Concave 8 Hydrocone

Concave 8 Hydrocone has 6 arms and weighs approximately 425 kg, sold in Avangard in both manganese steel and molybdenum manganese steel, in raw and machined forms.

Application of Hydrocone Concave

The application of concaves alongside the type of mantle and top shell in the Hydrocone crusher is specified as shown in the table below. As you can see, model 2 is a fine crusher, model 4 is an intermediate crusher, and models 5.5, 7, and 8 are coarse crushers.

فارسی

فارسی  Arabic

Arabic