[rank_math_breadcrumb]

Hydrocone Crusher Parts

Hydrocone crusher parts are components of the Hydrocone sand maker crusher, which is a type of cone crusher. It includes the mantle, concave, topshell, and bottomshel, and other hydrocone crusher parts that will be introduced later. These parts are used for the crushing of stones and minerals. Using the Hydrocone crusher can increase production efficiency and produce a higher volume of pebbles and sand with the same input as other crushers. The Hydrocone crusher is composed of various diverse parts such as the bottomshel, topshell, concave, mantle, head center, and bearings, steel bushing, eccentric bushing, and other components. The three main parts – named concave, mantle, and the Hydrocone oil pump – play the main role in the operation of this crusher. These components, by working together and interacting effectively, bring about the correct operation of the Hydrocone crusher. Using this device can increase production efficiency and produce a greater volume of pebbles and sand with the same input as other devices. For price inquiries and purchasing Crusher Parts, cone crusher prices, contact the sales unit of Avant-garde Holding.

Purchasing Hydrocone Crusher Parts

Avant-garde Company, with over 20 years of experience in the purchase, sale, production, design, and casting of all Hydrocone crusher parts and Superior crusher parts in various alloys, offers the best quality and reasonable prices, ready to provide services to esteemed customers. To buy Hydrocone crusher parts and high-quality Hydrocones with guaranteed authenticity, please contact our technical and sales team at Avant-garde.

Price of Hydrocone Crusher Parts

The Hydrocone crusher device is a type of modern crusher. Due to the particular features of this device, it is considered one of the most widely used types of crushers today. The following includes the price list of Hydrocone crushers along with a Hydrocone catalog and tutorial video and methods for purchasing various Hydrocone crushers for your information. Dear visitor, to receive the price list of Hydrocone crusher parts and technical specifications of Hydrocone crushers, you can contact the sales unit and promptly receive the prices of Hydrocone crusher parts.

Price List of Hydrocone Crusher Parts

| Row | Description | Price |

| 1 | Price of Mantle 2 Hydrocone | Contact Us |

| 2 | Price of Mantle 4 Hydrocone | Contact Us |

| 3 | Price of Superior Mantle | Contact Us |

| 4 | Price of Concave 2 Hydrocone | Contact Us |

| 5 | Price of Concave 4 Hydrocone | Contact Us |

| 6 | Price of Concave 5 Hydrocone | Contact Us |

| 7 | Price of Concave 5/6 Hydrocone | Contact Us |

| 8 | Price of Concave 7 Hydrocone | Contact Us |

| 9 | Price of Concave 8 Hydrocone | Contact Us |

| 10 | Price of Topshel Hydrocone | Contact Us |

| 11 | Price of Bottomshell Hydrocone | Contact Us |

| 12 | Price of Head Center Hydrocone | Contact Us |

| 13 | Price of Hydrocone Gland | Contact Us |

| 14 | Price of Steel Bush | Contact Us |

| 15 | Price of Extruding Bush | Contact Us |

| 16 | Price of Piston Bush | Contact Us |

| 17 | Price of Pulley Bush | Contact Us |

| 18 | Price of Steel Pulley Bush | Contact Us |

| 19 | Price of Corrugated Bush | Contact Us |

| 20 | Price of Spider Bush | Contact Us |

| 21 | Price of Large Pulley | Contact Us |

| 22 | Price of Mantle 2-36 | Contact Us |

| 23 | Price of Small Pulley | Contact Us |

| 24 | Price of Packing | Contact Us |

| 25 | Price of Piston Plate | Contact Us |

| 26 | Price of Concave 4-36 | Contact Us |

| 27 | Price of Housing Shell | Contact Us |

| 28 | Price of Piston | Contact Us |

| 29 | Price of Collar | Contact Us |

| 30 | Price of Housing Caps | Contact Us |

| 31 | Price of Crown Gear | Contact Us |

| 32 | Price of Pinion Gear | Contact Us |

| 33 | Price of Crown Ring | Contact Us |

| 34 | Price of Cast Iron Dust Seal Ring | Contact Us |

| 35 | Price of Hydrocone Main Shaft | Contact Us |

| 36 | Price of Housing Shaft | Contact Us |

| 37 | Price of Hydrocone Shaft Sleeves | Contact Us |

Related article: Jaw Crusher Parts

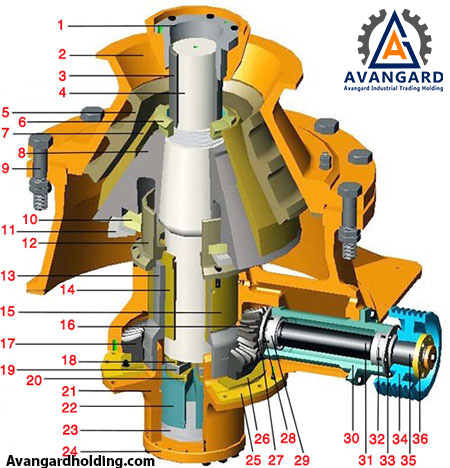

Components of Hydrocone Crusher Parts

The Hydrocone crusher is a type of cone crusher composed of the mantle and concave and other important components that will be mentioned below, used for crushing minerals and stones.

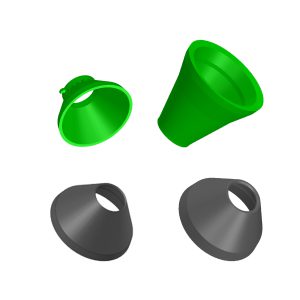

1. Hydrocone Mantle

The Hydrocone Mantle is a crucial part of the Hydrocone crusher, responsible for crushing stones. This piece is placed on the main shaft and inside the Hydrocone concave, rotating around its axis. The Hydrocone Mantle is made of manganese steel or manganese-molybdenum steel, and is held in place at the top by a tightening nut. Due to its exposure to severe abrasion, it requires periodic replacement, which should be done regularly based on the input rock material and monthly production. Mantle 2 and Mantle 4 are among the most commonly used types.

2. Hydrocone Concave

The Hydrocone Concave, unlike the mantle which has an eccentrically rotating motion, functions as a fixed component. This part is located within the bottomshel and topshel of the Hydrocone and is made of manganese steel and manganese-molybdenum steel. The Hydrocone Concave plays a fundamental role in the crushing operations within the Hydrocone and is responsible for crushing stones. Due to its exposure to intense abrasion, to optimize production and protect the internal parts of the machine, it should be periodically replaced based on the rock input material and monthly production volume. Concave 2 and Concave 4 are among the most frequently used.

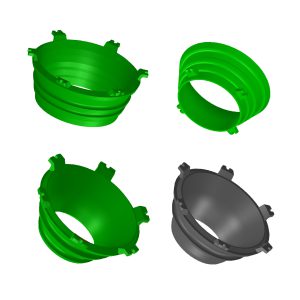

3. Bottomshel and Topshel of Hydrocone

The bottomshel and topshel are two main chambers of the Hydrocone crusher, made from carbon steel. The topshel is mounted above the bottomshel, and rocks enter the concave from the top, which is located inside the topshel.

4. Hydrocone Head Center

The head center is a conical piece made of carbon steel, tasked with holding the Hydrocone Mantle on the shaft.

5. Main Shaft of Hydrocone

The main shaft of the Hydrocone plays a vital role; it is rotated with the help of the eccentric bushing. The shaft rod is made from MO40 steel, which synchronizes with the rotation of the Hydrocone Mantle, and the rotational motion of the eccentric main shaft causes the angle between the mantle and concave to change. Additionally, this shaft is also responsible for controlling the Hydrocone jack.

6. Hydrocone Bushes

In the Hydrocone, different types of bushes are used, each with specific functions. For example, the spider bush is placed above the topshel, tasked with securing the shaft, while the eccentric bush causes the rotational movement of the main shaft. These bushes include corrugated bush, steel bush, eccentric bush, bronze bush, steel bush, piston bush, and cast iron bush.

7. Pinion and Crown Gear of Hydrocone

The pinion is a shaft connected to the pinion shaft and has helical gear teeth at its head. These gears transfer the rotational movement from the pinion end to the crown gear. The crown and pinion gears of the Hydrocone reduce the shaft speed from 480 to 8 rounds per minute, and also increase torque, serving the primary transfer of force to the crusher motor.

8. Thrust Bearings of Hydrocone

Thrust bearings - lens, steel, and bronze types - are used to enhance cooling, improve lubrication, and increase efficiency in lubrication operations. The above components are among the most important consumable parts of the Hydrocone crusher, and the procurement, purchase, sale, production, design, and casting of these components are among the services offered by the Avant-garde Holding.

Related article: Impact Crusher Parts

Components of Hydrocone Device

| Part Number | Part Name | Part Number | Part Name |

| 1 | Tall Spider | 19 | Steel Thrust Washer |

| 2 | Topshel | 20 | Flat Thrust Washer |

| 3 | Shaft Sleeve | 21 | Bowl |

| 4 | Main Shaft | 22 | Piston Bush |

| 5 | Concave | 23 | Piston |

| 6 | Shaft Nut | 24 | Piston Plate |

| 7 | Mantle | 25 | Crown Wheel Ring |

| 8 | Head Center | 26 | Flat Crown Wheel Fiber |

| 9 | Main Bolt | 27 | Housing Cover |

| 10 | Dustproof Feeder | 28 | Bearing 22219 |

| 11 | Dustproof Ring | 29 | Housing Shell |

| 12 | Dust Collar | 30 | Housing Shaft |

| 13 | Steel Bush | 31 | Bearing 7219 |

| 14 | Eccentric Bush | 32 | Housing Cover |

| 15 | Corrugated Bush | 33 | 46 cm Housing Pulley |

| 16 | Pinion Gear | 34 | Pulley |

| 17 | Crown Wheel Gear | 35 | Iron Bush Pulley Cup |

| 18 | Lens Thrust Washer | 36 | Cover |

Types of Hydrocone Crusher Parts

The Hydrocone crusher device consists of various replaceable parts, some of which due to direct contact with input minerals wear out more quickly and need replacement. The mantle and concave are among the most crucial of these parts. Hydrocone crusher spare parts are produced in two materials: manganese steel and molybdenum-manganese steel. Avangard Holding, with over two decades of experience and high academic qualifications from reputable domestic and foreign universities, has the expertise to produce the best types of Hydrocone crusher components.

| Part | Part Name | Part Number | Part Name |

| 1 | Corrugated Bush | 27 | Pinion Gear |

| 2 | Bottom Shell | 28 | Housing Cover |

| 3 | Housing Bearing | 29 | Dust Collar |

| 4 | Housing Spacer | 30 | Thrust Plate |

| 5 | O-Ring | 31 | Shock Absorber |

| 6 | Top Shell and Bottom Shell Wrench | 32 | Packing Plate |

| 7 | Steel Bush | 33 | Frame |

| 8 | Cast Iron Pulley Bush | 34 | Main Shaft |

| 9 | Hydroset Bush | 35 | Housing Shaft |

| 10 | Eccentric Bush | 36 | Dust Ring |

| 11 | Spider Bush | 37 | Crown Wheel Thrust Washer |

| 12 | Steel Pulley Bush | 38 | Steel Thrust Washer |

| 13 | Dynamo Pulley | 39 | Spider Oil Seal |

| 14 | Housing Pulley | 40 | Spider Cap |

| 15 | Large Palani | 41 | Concave |

| 16 | Small Palani | 42 | Shaft Sleeve |

| 17 | Packing | 43 | Mantle |

| 18 | Housing Shell | 44 | Gland |

| 19 | Top Shell | 45 | Dustproof |

| 20 | Lubrication Tank and Jack | 46 | Hydroset Base |

| 21 | Gland Screw and Nut | 47 | Lens Thrust Washer |

| 22 | Bottom Shell Screw and Nut | 48 | Flat Thrust Washer |

| 23 | Concave Screw and Nut | 49 | Head Center |

| 24 | Piston | 50 | Bush Pulley Cup |

| 25 | Shaft Nut Ring | 51 | Shaft Nut |

| 26 | Crown Wheel Gear |

How Hydrocone Crusher Parts Work

The basic operation of the Hydrocone cone crusher is such that materials are crushed after entering the top of the crushing chamber by rotational and eccentric motion (off-axis and uneven) between the concave and mantle. The crushed materials exit from the bottom of the crusher and proceed to the next stage of processing or separation. The device's features such as low wear, high production and efficiency, and easy maintenance make it popular among mine owners. This crusher is sensitive to moisture and its performance diminishes, making it unsuitable for use with wet rocks. Timely replacement of the consumable parts increases the time required for Hydrocone crusher repair.

Related article: Casting Services

Types of Hydrocone Crushers

The Hydrocone is conically designed and in the initial and secondary stages of extraction, converts mined rocks into nugget forms for subsequent use. These devices are produced in various sizes including 2-36, 4-36, 5-36, 5.5-36, 6.5-36, and 8-36. These sizes are referred to as fine crusher, medium crusher, and coarse crusher respectively. It should also be mentioned that in some mines, 45-inch Hydrocone devices are also used.

| Technical Specifications of Different Hydrocone Crusher Types | |||||||

| Row | Model | Max Input Dimensions (mm) | Output Material Dimensions (mm) | Production Capacity(t/h) | Motor Power (kw) | Device Weight (ton) | Dimensions (Length*Width*Height) (mm) |

| 1 | 36*2 Fine Crusher | 40 | 0-30 | 80 | 90 | 11 | 3000*1900*3800 |

| 2 | 36*4 Fine Crusher | 60 | 0-30 | 100 | 90 | 11 | 3000*1900*3800 |

| 3 | 36*5 Medium Crusher | 100 | 0-30 | 140 | 90 | 11 | 3000*1900*3800 |

| 4 | 36*7 Coarse Crusher | 160 | 0-50 | 160 | 90 | 11 | 3000*1900*3800 |

| 5 | 36*8 Coarse Crusher | 200 | 0-60 | 180 | 90 | 11 | 3000*1900*3800 |

فارسی

فارسی  Arabic

Arabic