[rank_math_breadcrumb]

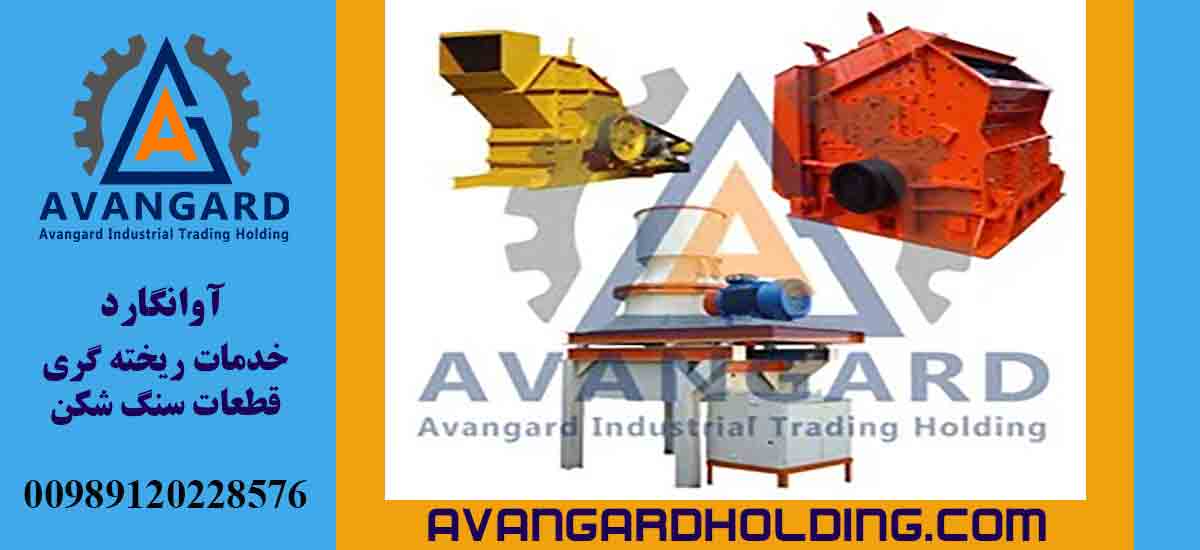

Crusher and Road Construction

Avangard Company, with over two decades of experience in the crusher and road construction industry, as one of the pioneers in casting services, purchase, sale, manufacturing, and production of crusher parts, crusher machines and equipment for sand and gravel mines, cement factories and other crushing machinery necessary in the mining industry, operates. We also take pride in supplying teeth and undercarriage parts for construction machinery such as loaders, bulldozers, excavators and other spare parts with superior quality and competitive pricing. Our expert team delivers products that offer long lifecycle and matchless efficiency, utilizing state-of-the-art technologies and high-quality raw materials. We continuously strive to improve quality standards and provide excellent after-sales services to our customers. Please contact Avangard Holding’s sales experts for purchasing advice on crusher and road construction parts.

Crushing Operations by Crusher Machines

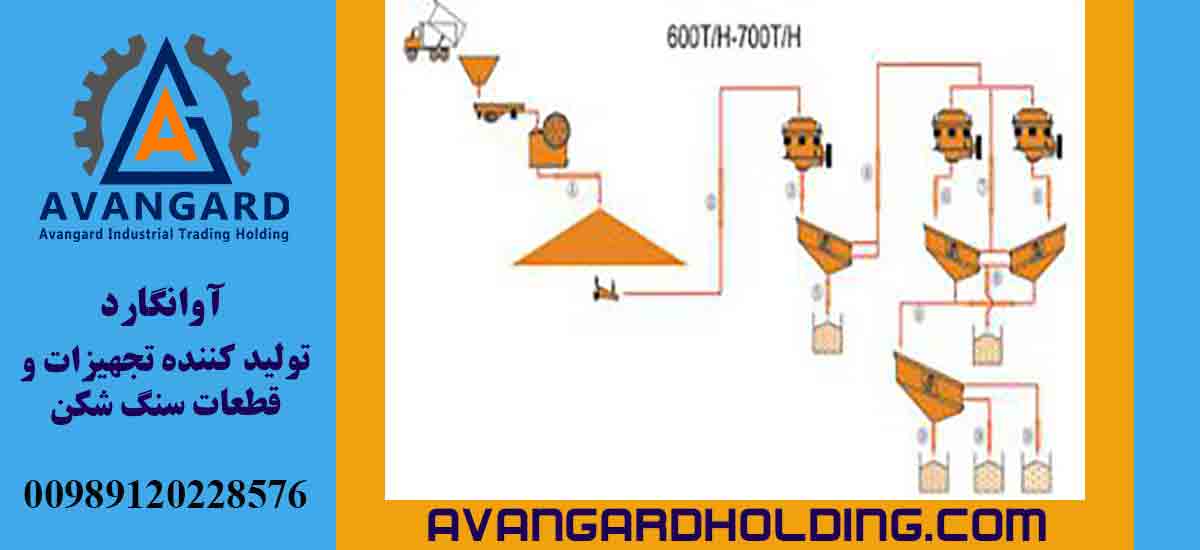

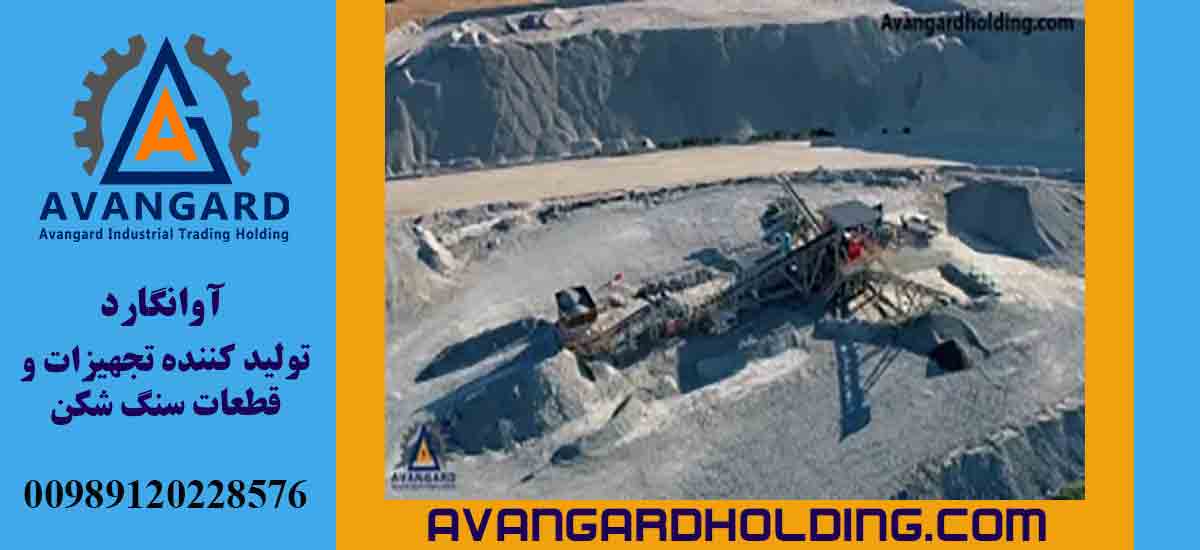

For the production of sand and gravel in sand and gravel mining workshops, this task is performed by crushers, which are categorized into three types: primary crusher, secondary crusher, and tertiary crusher, each capable of crushing stones to specified sizes. Initially, the rocks extracted from mines are directed to the crusher plant with the help of construction machinery. Subsequently, the rocks are crushed by crushers using abrasion-resistant crusher equipment incorporated within them, reducing them to sufficiently small sizes. In the subsequent stage inside the plant, the sand and gravel, or any impurities present, are cleaned and removed using other sand and gravel mining equipment and industrial crushers like sieves and sand washers installed in the mineral processing production line, ultimately preparing them for use in construction, road building, and structural engineering.

Sand and Gravel Mining Equipment

Regarding the types of sand, gravel, and mineral crusher machinery and sand plant machinery, we can refer to the mining crusher, sand washer, sieve, feeder, and conveyor which are discussed in the following sections. For purchasing a crusher, ordering, manufacturing, production or price inquiries, please access the sand and gravel mining equipment section or contact Avangard's sales department.

Related article: Design and Modeling

Types of Crusher Machines Based on Operational Types

Crusher machines are used extensively in construction industries and various mines to crush and grind rocks and minerals to produce crushed materials. These crushing machines play a vital role in mineral extraction, road building, construction, and building material production processes, which will be discussed in the types mentioned below.

1- Bohringer Crusher:

The Bohringer Crusher, a subset of the impact crusher, is sometimes referred to as the Bohringer Cobit HS Impact Crusher and is used for crushing stones and minerals with medium to high hardness, operating automatically. The HS hammer plays a crucial role in this device.

2- Gyratory Crusher:

The Gyratory Crusher is used for crushing and grinding minerals with high hardness and diverse compositions and is usually utilized in the first stage of crushing.

3- Jaw Crusher:

The Jaw Crusher is used to crush stones and minerals as a primary crusher alongside other crushers, providing strong and reliable performance. The jaw plate and jaw holder are the main components of this machine.

4- Cobit Crusher:

The Cobit Crusher is a subset of impact crushers that uses impact force to perform crushing operations and is utilized in various industries such as sand and gravel mines, construction, and road construction. In this device, the Cobit 120 and Cobit 180 hammers are sensitive and high-consumption parts.

5- Hydrocone Crusher Machine:

The Hydrocone Crusher Machine is primarily used as a secondary crusher in mining, designed for crushing rocks and minerals using hydraulic pressure to produce crushed materials of various sizes. The mantle and concave types play an important role in this machine.

6- Rabbit Sand Maker Machine:

The Rabbit Sand Maker is considered a type of impact crusher that is extremely used in the industry of crushing and is employed for producing sand and gravel in the construction and road sector. It is noteworthy that the rabbit sand maker hammer made of manganese steel and manganese-molybdenum steel is considered one of the vital components in this machine.

7- Rock-on-Rock Sand Maker Machine:

The Rock-on-Rock Sand Maker Machine is used for producing high-quality building materials such as sand and gravel.

Screener Machine

Screener machines are employed in sand and gravel mines for separating and classifying crushed materials and sands. The screener separates materials by vibration, rotation, or inclined surfaces and is considered one of the primary stages in sand production processes, which we will discuss further.

1- Vibrating Screener Machine:

The Vibrating Screener Machine uses vibration motion to separate crushed materials and sands of different sizes.

2- Rotary Screener Machine:

Rotary Screener Machine segregates materials in a circular motion and classifies them based on size and properties.

3- Grizzly Screener Machine:

The Grizzly Screener Machine is used for separating large-sized crushed materials and preventing unsuitable materials from entering the next stages.

Sand Washer Machine

The Sand Washer Machine is used in sand and gravel mines and asphalt plants for washing and cleaning mineral materials and sands, effectively removing impurities and producing high-quality sand. It is manufactured in various types as discussed in the sand washing section.

1- Single Spiral Sand Washer:

The Single Spiral Sand Washer is used for washing mineral materials and sand utilizing a single spiral and is highly effective in cleaning materials.

2- Double Spiral Sand Washer:

This machine uses two spirals for washing mineral materials and is more efficient than single spiral machines.

3- Scrubber or Mixing Wash Sand Washer:

This machine uses a mixing wash technology to scrub the surface of materials for washing mineral materials.

4- Dual-Axis Bucket Sand Washer:

This dual-axis machine is used for washing and cleaning mineral materials and sand, offering efficient performance.

5- Thickener Machine:

This machine is used for dewatering and rolling sand and mineral materials from water, primarily serving as a protective water resource strategy.

6- EvoWash Sand Washing Plant:

This machine is used for washing and cleaning sand with advanced technology, aiding in the production of high-quality sand.

Feeding Machines

Feeding machines are used in sand and gravel mines to transfer and feed crushed materials and sand to crushing and washing machines. These machines regulate flow and material feeding, enhancing industrial production line efficiency and performance. Visit the feeder section for comprehensive information.

1- Vibrating Feeder Machine:

The Vibrating Feeder Machine uses vibration motion to continuously and consistently transfer materials to crushing or washing machines.

2- Grizzly Feeder Machine:

The Grizzly Feeder Machine is used to separate crushed materials from soil and larger rocks, preventing unwanted materials from entering crushing devices.

3- Shaker Feeder Machine:

The Shaker Feeder Machine transfers and feeds materials to crushing and washing devices and is suitable for small to medium-sized crushed materials.

Conveyor Belt Machine

Conveyor belt machines are used in sand and gravel mines for direct and continuous transfer of crushed materials, sand, and other materials from one point to another. These machines enhance material transfer efficiency and improve production processes; for ordering and purchase information visit the belt conveyor page.

1- Fixed Loading Belt Conveyor Machine:

This machine is used to transfer materials from a fixed point to another in sand and gravel mines, such as transferring materials from a jaw crusher to a cone crusher.

2- Mobile Loading Belt Conveyor Machine:

This machine is used to transfer materials from one point to another with mobility, such as transferring materials from the mine to trucks or from trucks to other production sections.

Types of Crusher Parts

Crusher parts for sand and gravel crushing devices, available in various impact crusher parts, jaw crusher parts, hydrocone crusher parts, and other spare parts for grading and crushing equipment, are available at Avangard. Notably, these device hammers, crafted with high quality, competitive prices, and suited for mining environments, are produced in cast alloy types such as Ni-Hard 4, high chrome, manganese steel, and manganese-molybdenum steel, further described below.

Impact Crusher Parts

Impact crusher parts include a variety of hammers, rotors, cheek plates, liners, and other consumables used in the mineral crushing process, such as sand and gravel. These play vital roles; for example, hammers serve to strike or act as protectors for the device body, typically made from wear-resistant alloys like manganese steel and sometimes manganese-molybdenum steel, Hi Cr cast iron, and Ni-Hard 4, further detailed in popular types.

1. Bohringer Crusher Parts:

Bohringer crusher parts, including commonly used hammers like HS7, HS10, HS11, HS14, and HS16, are manufactured with wear-resistant materials like manganese steel, Ni-Hard 4, and high chrome. Besides HS7, HS10, HS11, HS14, HS16 materials, parts like cheek plates, rotors, and liners or HS10 anvils are also significant and frequently consumed.

2. Parker Crusher Parts:

Among Parker crusher parts, the hammer types 104, 103, and 3 are more frequently consumed, typically made from manganese steel and manganese-molybdenum steel. In addition to the hammers, Parker rotors 104 and 103, arms 104 and 103, and RD7 and RC 226 cheek plates, along with other parts, are essential and available at Avangard with high quality and competitive pricing. Purchase through contact with sales experts is possible.

3. Sand Maker Crusher Parts:

Among commonly used sand maker crusher parts are rabbit hammers, anvils, rotors, cheek plates, and other consumables. Rock-on-rock sand maker parts such as hammers and anvils are produced from high-quality, wear-resistant alloys, critical in sand production from minerals.

4. Cobit Crusher Parts:

Cobit crusher parts are highly useful in the sand and gravel crushing industry, particularly in road construction and sand mines. Among these, Cobit 120, Cobit 180, and Cobit 240 hammers are highly consumed and are produced in Avangard with high quality from manganese steel and molybdenum-nickel steel, as well as cast iron with high or Hi Cr chrome properties. They are also accompanied by consumption of cheek plates, liners, and anvils.

Related article: Casting Raw Materials

Jaw Crusher Parts

Among frequently used jaw crusher parts in jaw crusher devices for crushing processes of minerals like sand and gravel are cheek plates, jaws, toggle, anvils, and other consumables. These can be purchased at affordable prices and high quality compliant with global standards, through Avangard's sales unit. Further details on jaw crusher parts are discussed below:

1- Jaw Plate:

Jaw plates are divided into fixed and mobile cheeks, also known as fixed jaw and mobile jaw, cast in various sizes at Avangard from manganese steel and manganese-molybdenum steel.

2- Jaw Plate Holder:

The jaw plate holder, holding the jaw plate in the jaw crusher, is divided into fixed and mobile jaw holders, cast in different dimensions according to the jaw plate size and jaw crusher type at Avangard, for example, a 80*55 jaw plate holder is used with a 80*55 jaw plate. The materials used for this component match those of the cheek plates, mainly produced from manganese steel and manganese-molybdenum steel.

Hydrocone Crusher Parts

Among the most frequently consumed hydrocone crusher parts produced in the casting factory for hydrocone or cone crushers are the concaves, mantles, top shells, bottom shells, main shaft nuts, and other spare parts. Various hydrocone machines, including sizes 36, 45, 48, 54 inches as well as Symons 66-inch and 84-inch machines, require specific mantles, concaves, and other consumables, all of which are detailed in the hydrocone crusher parts sales section. For more information on mantles and concaves, accompany us below.

Hydrocone Crusher Mantle:

Hydrocone mantles are produced in casting factories from manganese steel or manganese-molybdenum steel. The mantle fits inside the concave of the hydrocone crusher, with sizes like 2-36 and 4-36 being commonly used.

Hydrocone Crusher Concave:

Hydrocone concaves are manufactured and sold from manganese steel or manganese-molybdenum steel in casting factories, placed externally to the hydrocone crusher mantle, with popular sizes being concave 2-36 and concave 4-36. For ordering various crusher parts, go through Avangard; our specialists are eager to meet the needs of respected industrialists in the mining sector.

```html

Teeth and Undercarriage Parts for Various Road Construction Machinery

Teeth and undercarriage parts for road construction machinery are produced according to global standards with reliable quality, made of alloy steel and offered at competitive prices. At Avangard, various types of teeth, corners, rippers, overlays, and adapters for machinery like excavators, loaders, bulldozers, graders, and other construction and loading machines are manufactured with renowned brands like Caterpillar, Komatsu, Hitachi, Volvo, Zoomlion, New Holland, Doosan, Daewoo, Chinese loaders, Liebherr, Bobcat, Hepco, and International, using forging and casting methods. You can contact the sales unit of Avangard or visit the teeth and undercarriage parts sales page to purchase and receive catalogs along with the technical details of all spare parts for construction machinery's undercarriage.

Grader:

A grader is an operational machine that works in the process of slope adjustment and leveling embankments and cuttings along the route. The term "slope adjustment" refers to setting the shape and size of cuttings and embankments and balancing them. Note that various undercarriage parts of graders are available at Avangard.

Loader:

The loader is categorized as a transportation device in the tractor category and is actually a type of bucket tractor. It is one of the most used machines in construction and road-building sectors, commonly manufactured in factories under brands like Komatsu, Hepco, Hitachi, Kawasaki, Volvo, Caterpillar, and others, both tracked and wheeled. Note that all undercarriage parts for loaders, including teeth, rippers, etc., are manufactured by Avangard.

Excavator:

An excavator is one of the heavy construction machines used for moving large objects and materials or resources and for excavation. It is usually employed for trenching, digging holes, foundations, as well as demolishing and mining operations. The excavator features an articulated arm, bucket, and rotating cab mounted on tracks or wheels. Equipped with advanced technology, it can carry attachments like rock jet, hammers, metal shears, drills, grapples, forks, and others. Dear industry professionals, procure excavator undercarriage parts with excellent quality from Avangard.

Bulldozer:

A bulldozer is one of the machines used in construction and civil operations, its movement facilitated by tracks. This tractor is equipped with a steel blade at the front, capable of handling large volumes of snow, earth, gravel, sand, debris, etc., during work. The bulldozer is composed of a main tractor and a blade, with the blade connected to the tractor by a frame system. You can now purchase bulldozer undercarriage parts by contacting Avangard's sales specialists.

Purchase and Price of Crusher Equipment and Road Construction

Avangard company, focusing on quality and reliability, produces and offers crusher and road construction equipment with superior technical specifications. Avangard provides competitive and suitable prices, enabling the purchase of industrial equipment and supplying the necessary equipment for customers. To inquire about the price list for crushers, mining crusher equipment, sand and gravel crusher machines, complete crusher lines, various industrial machines, mining machinery, and the buying and selling of mineral materials, contact the sales experts of Avangard Holding.

```

فارسی

فارسی  Arabic

Arabic