[rank_math_breadcrumb]

Crusher Parts

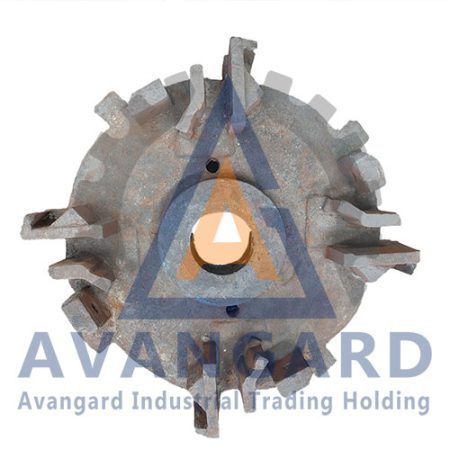

Crusher parts for sand and gravel mining equipment are categorized into three sections: impact crusher parts, jaw crusher parts, and hydrocone or cone crusher parts, which are considered important types of crusher equipment. Subcategories include main parts from Bohringer HS crushers, sand maker parts, Parker crusher parts, impact hammer crusher parts, jaw plates, crusher jaws, hydrocone mantle, and hydrocone concave. These spare parts are essential for the efficient and correct operation of crusher jaws, which include shafts, bearings, belts, electric motors, cylinders, rings, hammers, gears, and other components used in the crushing process in industries such as mining, sand and gravel quarries, crusher and road construction, and building and construction projects.

These parts impact the price of crusher parts based on manufacturing process and casting methods, influenced by the alloy composition at the time of purchase and sale. Avangard Holding, a manufacturer of crusher parts, provides the best crusher spare parts and crusher equipment.

Price of Crusher Parts

For information about the price list of crusher parts, hammer crusher price, crusher mill price, and purchasing high-quality crusher spare parts with valid warranty, contact our experts at Avangard Manufacturing Company. Avangard specializes in casting various crusher parts and consumables for impact crushers, hydrocone, jaw, and hammer crushers made of manganese, manganese molybdenum, nihard cast iron, and chromium cast irons.

We apologize, all prices are currently being updated. Please contact the Avangard sales unit for price inquiries.

| No | Description | Price |

| 1 | HS10 Hammer Price | Contact Us |

| 2 | HS10 EDGE Hammer Price | Contact Us |

| 3 | HS11 Hammer Price | Contact Us |

| 4 | HS7 Hammer Price | Contact Us |

| 5 | HS14 Hammer Price | Contact Us |

| 6 | Side Collar with Hub Price | Contact Us |

| 7 | Parker 103 Price | Contact Us |

| 8 | Parker 104 Price | Contact Us |

| 9 | Rabbit Sand Maker Price | Contact Us |

| 10 | HS10 Pipe Price | Contact Us |

| 11 | Perforated Side Collar Price | Contact Us |

| 12 | Kubit 120 Price | Contact Us |

| 13 | HS10 Anvil Surface Price | Contact Us |

| 14 | HS10 Pulley Price | Contact Us |

| 15 | C01 Hammer Price | Contact Us |

| 16 | DMK01 Hammer Price | Contact Us |

| 17 | Kubit 180 Price | Contact Us |

| 18 | YY06 Hammer Price | Contact Us |

| 19 | PST 70 Hammer Price | Contact Us |

| 20 | PST 78 Hammer Price | Contact Us |

| 21 | 130 Ton Pendulum Hammer Price | Contact Us |

| 22 | HS10 Lower Bracket Price | Contact Us |

Purchasing Various Crusher Parts from Avangard

Avangard Holding is proud to leverage over two decades of experience and advanced education from prestigious universities both domestically and abroad, as well as specialized knowledge in steel casting and casting iron. We provide over a thousand parts, including the production of crusher parts or casting crusher parts, and consumables for sand and gravel quarries, cement industries, and mineral processing with alloys such as carbon steels, low-alloy steels, manganese steel casting (Hadfield casting), high-chromium, nihard 4 cast iron, and high-chromium irons. These parts are used in the crushing process and to protect the machine body from impacts and blows. Due to their exposure to wear, these parts are made of various materials based on the mining conditions, highlighting the importance of casting crusher parts.

Introduction to Crusher Parts

Choosing correctly is an art; by selecting Avangard Holding as a leading manufacturer and casting expert of mineral parts, you enhance the production efficiency of your operation. Using specialized casting for mining parts or casting hammer crusher parts for sand and gravel mines, while selecting the right material (alloy) based on the environmental conditions of your mine, enhances production efficiency. The most important aspect of selecting parts is leveraging the expertise and specialized knowledge of the technical engineering team at Avangard Holding.

Components of Various Types of Crusher Machines

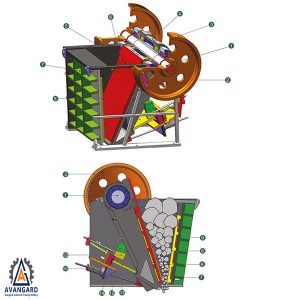

Crusher machines are primarily categorized into three main types: impact crushers which use a rotating rotor with detachable hammers to crush materials; jaw crushers which have two jaws and crush materials by applying pressure and movement; and cone crushers or hydrocones, which have a cone that rotates to crush materials.

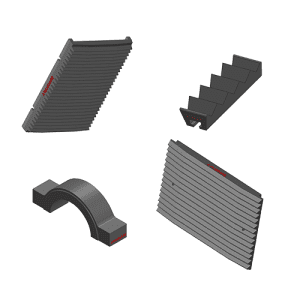

Components of Impact Crusher Parts

Impact crusher parts, including Bohringer HS parts, sand makers, Parker crushers, and Kue-Ken crusher parts, all belong to the subset of impact crusher components. These parts are used to enhance the performance and efficiency of impact crushers in the material crushing process, playing a significant role in the crushing of various materials, including minerals and rocks in mines. Bohringer, sand makers, Parker, and Kue-Ken improve the capabilities and efficiency of impact crushers, aiding in better material crushing and production of crushed materials for further processing.

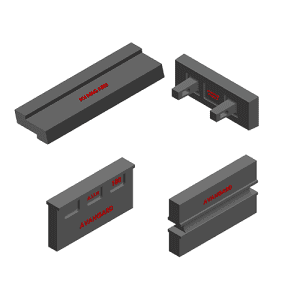

Components of Jaw Crusher Parts

Jaw crusher parts, known as the primary crusher, consist of a movable jaw and a stationary jaw, along with other critical components mentioned below, used for crushing minerals and rocks in mining during the first stage of crushing, then transferred to subsequent stages.

1. Shaft

2. Balance Weight

3. Pulley

4. Toggle Plate

5. Side Liners

6. Movable Jaw

7. Jaw Block

8. Fixed Jaw

9. Fixed Jaw Holder

10. Toggle Spring

11. Rear Jaw Plate

12. Rear Jaw Channel

13. Wedge

14. Rear Jaw Holder

The listed components are among the most important consumable parts of jaw crushers. Their procurement, purchase, sale, design, production, and casting with the highest quality and lowest price are possible at Avangard Company.

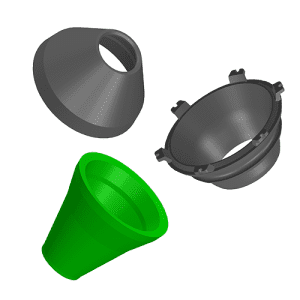

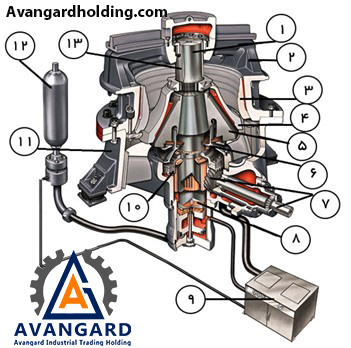

Components of Hydrocone Crusher Parts

Hydrocone crusher parts are types of cone crushers, consisting of a mantle and concave, along with other critical components listed below, used for crushing minerals and rocks.

1. Main Shaft

2. Top Shell

3. Concave

4. Mantle

5. Head Center

6. Dust Collar

7. Pinion Gear

8. Hydraulic Piston

9. Oil Tank

10. Crown Wheel

11. Bottom Shell

12. Accumulator

13. Shaft Sleeve

The above components are among the most important consumable parts of hydrocone crushers, and their procurement, purchase, sale, design, and casting are services provided by Avangard Holding.

Related article: Avangard Casting Services

Types of Crusher Parts

To make the best choice, be informed about all the details, conditions, and benefits of using different materials of parts. Therefore, we intend to comprehensively introduce you to various crusher parts and their different materials.

Below are some of the most commonly used auxiliary crusher parts listed for reference. For price inquiries, orders, technical specifications, and catalogs, please contact the crusher parts store at Avangard Holding.

Jaw Crusher

This crusher crushes large and coarse rocks (larger than 20 centimeters) which cannot be processed by other crushers, delivering them further for additional crushing by other crusher machines. Parts used in this type of machine include fixed and movable jaw plates, jaw holder, bearings, etc.

Fixed Jaw Plate of Jaw Crusher

The fixed jaw plate in jaw crushers acts as a fixed point against which the movable jaw operates. This jaw serves as a solid base for the performance of the movable jaw and withstands the pressure and forces exerted on the crusher during the crushing process, typically made from manganese steel or manganese molybdenum alloy.

Movable Jaw Plate of Jaw Crusher

The movable jaw plate in jaw crushers acts in a moving manner and is used to crush materials. This jaw continuously moves up and down, compressing and crushing materials between the movable and fixed jaw plates, usually manufactured from manganese alloy or manganese molybdenum in a casting factory.

Jaw Holder of Jaw Crusher

The jaw holder in a jaw crusher is made from steel or wear-resistant manganese steel or Hadfield steel. Its primary function is to hold and support the fixed and movable jaws of the crusher during the material crushing process.

Hydrocone Crusher

Cone crushers are available in various sizes and are used based on the size of their openings. They come in two types: Superior or Gyratory (extra coarse crushers). They are named using two numbers (36*2), where the smaller number represents the opening size and the larger number, which is typically the same for all, equals "36 and denotes the diameter of the head center mounted on the main shaft, with the mantle located on top. In these crushers, mantles and concaves replace hammers and anvils.

Mantle of Hydrocone Crusher

The mantle of the hydrocone crusher is one of the main components of a cone crusher or hydrocone, used in sand and gravel mines to crush minerals and rocks. When materials enter the crusher, they are compressed and crushed between the surface of the mantle and the outer shell of the crusher, known as the concave.

Concave of Hydrocone Crusher

The concave of the hydrocone crusher works alongside the mantle in a cone crusher to crush minerals and rocks. When materials enter between the concave and hydrocone mantle, they are pressed and crushed under pressure and friction between their surfaces.

Impact Crusher

This crusher is used to crush materials smaller than 200 mm or sometimes up to 400 mm (depending on the dimensions of the crusher), utilizing a hammer and anvil system for crushing materials, with the hammers being movable and the anvils fixed.

Kubit Hammer Crusher

Kubit hammer is a key component in impact crushers, used for crushing hard materials. These hammers strike materials with high speed and energy to throw them to the anvils, breaking them into smaller sizes.

Sand Maker Hammer Crusher

Sand maker hammers in impact crushers are used to crush materials into sizes necessary for sand production. These hammers strike the materials at high speed, causing them to break and fragment further; the crushed materials are then separated to suitable sizes using sieving plates to produce sand.

Parker Hammer Crusher

Parker hammers in impact crushers are used for crushing hard materials. The Parker hammer crusher strikes the material at high speed, breaking it into smaller sizes, and is available in 3-103 and 104 types.

Bohringer Hammer Crusher

Bohringer Hammer Crushers HS are key components of impact crushers, used for crushing hard materials in mining. These HS hammers strike the incoming materials at high speed, reducing them to smaller sizes suitable for subsequent processing stages.

فارسی

فارسی  Arabic

Arabic