Conveyor Chain

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

What is a Conveyor Chain?

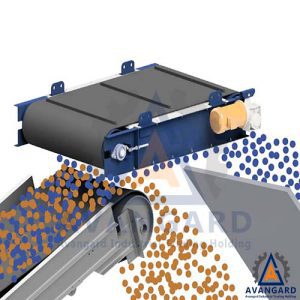

The conveyor chain or conveyor belt is one of the essential pieces of equipment in various industries used for transporting solid materials such as parts, packages, and bulk materials. This system, utilizing a strong and continuous chain connected to paddles or plates, allows for horizontal, inclined, or vertical movement of materials. Due to its robust and durable structure, the conveyor chain is capable of withstanding heavy loads and transporting materials over long distances.

Conveyor chains are produced in various types, including plastic, steel, and stainless steel, based on material type and operational conditions. Selecting the appropriate chain considering its mechanical properties, corrosion resistance, and durability is of particular importance. Additionally, the price of a conveyor chain depends on factors such as the quality of raw materials, design and dimensions, and chain manufacturing technology. For purchasing high-quality conveyor chains in line with modern standards, you can contact the sales experts at Avangard to receive the best guidance.

Features of Conveyor Chains:

- High resistance: Conveyor chains are made from quality and resistant materials, allowing their use in harsh and rugged industrial environments.

- Diversity of models: Conveyor chains are produced in various types with diverse capacities and dimensions to meet the needs of different industries.

- Flexibility: This system can be installed in production lines with various complexities and can be easily connected to automation systems.

- High safety: Conveyor chains are designed and built in compliance with safety standards to prevent accidents.

Applications of Conveyor Chains:

Conveyor chains are used in various industries including food, pharmaceutical, automotive, construction, and mining. Some important applications of conveyor chains include:

- Material transfer in production lines: Conveyor chains are used for transferring parts, raw materials, and semi-finished products in production lines.

- Distribution of materials in warehouses: This system is used for the automatic distribution of materials in warehouses and depots.

- Loading and unloading materials: Conveyor chains are used for loading and unloading materials from vehicles and storage tanks.

Types of Conveyor Chains

Conveyor chains are a key component of conveyor systems, used to move materials from one point to another. There are various types of conveyor chains, each designed for specific applications. Below are explanations of some types of conveyor chains:

Conveyor Chain Based on Number and Shape of Attachments:

Dual-sprocketed K1 Conveyor Chain (with wings): This type of chain has attachments on both sides perpendicular to the chain plate. The number and length of attachments can vary. This type is used for transporting heavy and bulky loads.

Low-Sprocket Conveyor Chain: C2082-4L has fewer attachments than the winged type and is typically used for transporting lighter loads.

High-Sprocket Conveyor Chain: C2082-2L, in contrast to the low-sprocket type, has more attachments and is used for carrying loads with more surface contact.

Without Sprocket Conveyor Chain: C2082 is without attachments and is used for carrying loads that do not require attachments, such as plates or sheets.

Conveyor Chain Based on Number of Rows:

Single-row Conveyor Chain B24 and B06 have one row of pins and bushes and are used for general applications. The numbers B24 and B06 refer to the geometric specifications of the chain.

Double-row or Double Conveyor Chain has two rows of pins and bushes and is used for heavier and longer loads.

Single-row Conveyor Chain generally refers to chains with one row of pins and bushes, including various types like B24 and B06.

Other Types of Conveyor Chains (In General):

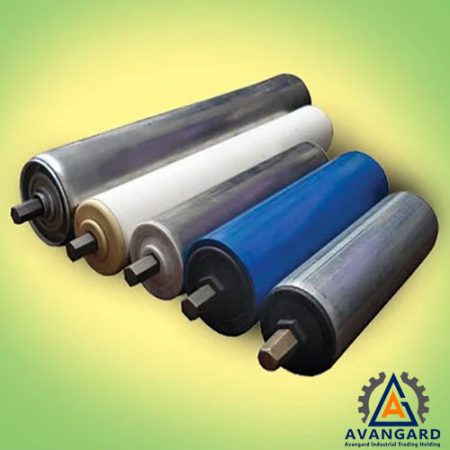

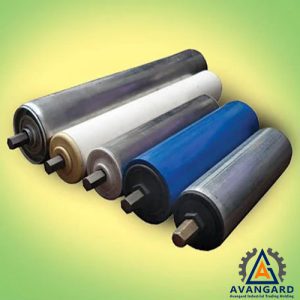

Roller Conveyor Chain: This type has rollers placed on it, used for reducing friction and moving heavier loads.

Modular Conveyor Chain: This consists of separate parts that can be easily assembled and disassembled.

Metal Plate Conveyor Chain: Formed from connected metal plates, it is used for transporting heavy and bulky loads.

| Chain Type | Main Features | Main Applications | Advantages | Disadvantages |

| Dual-sprocketed K1 (with wings) | Attachments perpendicular to the chain plate, high load capacity | Transport of heavy and bulky loads, heavy industries | High resistance, good stability against lateral loads | Higher cost, more complexity in installation |

| Low-sprocket C2082-4L | Less attachments, lighter weight | Lighter loads, food, and pharmaceutical industries | Lower cost, more flexibility | Lower load capacity compared to winged type |

| High-sprocket C2082-2L | More attachments, more contact surface with the load | Transport of loads with uneven surfaces, packaging industries | Better load stability, reduced slippage | Higher cost, more complexity in design |

| Without sprocket C2082 | Without attachments, smooth surface | Transport of plates and sheets, metal industries | Simplicity in design, lower cost | Lower load capacity, limitation on load type |

| Single-row B24, B06 | One row of pins and bushes, general application | Variety of industries | Simplicity, reasonable cost | Limited load capacity compared to multi-row types |

| Double-row (Double) | Two rows of pins and bushes | Transport of heavy and long loads | High load capacity, more stability | Higher cost, more complexity |

| Roller | With rollers, reduces friction | Heavy loads, steel, and cement industries | Reduced wear, increased lifespan | Higher cost, more sensitivity to contamination |

| Modular | Separate parts, high flexibility | Production lines with many changes, automotive industries | Flexibility, ease of maintenance | Higher cost, complexity in design |

* Choosing the suitable type of conveyor chain depends on various factors such as load type, transfer speed, route length, environmental conditions, and so on. It’s best to consult with Avangard’s specialist experts for the best choice of chain.

Some Important Points in Selecting a Conveyor Chain:

Chain Material: Conveyor chains are usually made from steel, cast iron, or specific alloys.

Chain Coating: Some chains feature coatings like galvanized or chrome to resist corrosion.

Manufacturing Standards: Conveyor chains should be produced according to international standards to ensure their quality and safety.

Purchasing Conveyor Chains:

For purchasing conveyor chains, first, define your needs. Depending on the material type and working conditions, various chains are available in the market. To purchase high-quality chains and receive free consultation, you can contact Avangard’s sales experts to make the best choice.

Selling Conveyor Chains:

As one of the reputable suppliers of conveyor chains, Avangard offers different types of this product in line with global standards for various industries. All products are sold with quality assurance and at competitive prices. For more information and purchases, contact Avangard Holding’s sales experts.

Price of Conveyor Chains:

The price of conveyor chains depends on various factors, including chain type, length, width, capacity, and raw materials. For exact pricing information on conveyor chains, you can contact Avangard’s sales experts.

Conclusion:

Conveyor chains, as a necessary piece of equipment in various industries, play a crucial role in increasing productivity and reducing production costs. With their unique features, they are a suitable option for transporting different types of materials under various conditions. For purchasing high-quality conveyor chains suited to your needs, you can trust Avangard.

فارسی

فارسی Arabic

Arabic

Reviews

There are no reviews yet.