What is a Double-Sided Sand Maker?

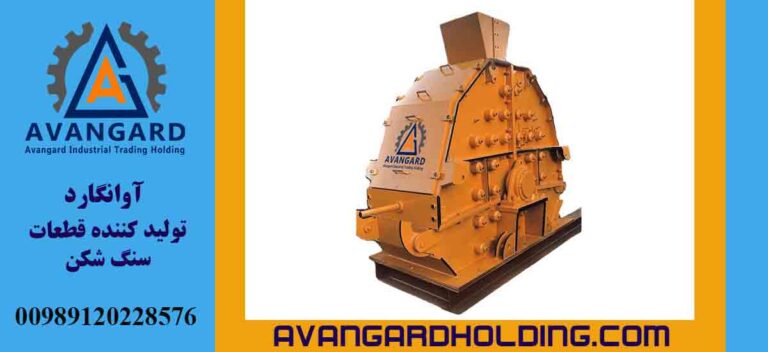

The Double-Sided Sand Maker is one of the essential machines in the crushing industry and the production of stone aggregates, particularly used in sand and gravel mines for producing crushed sand. This machine is capable of crushing hard and semi-hard rocks, functioning similarly to impact crushers. However, the main difference between the double-sided sand maker and other impact crushers lies in its structure, which features two anvils on both sides of the machine. This unique design increases the number of impacts, consequently boosting sand production efficiency.

In this machine, the input material size typically ranges between 0 to 150 mm, while the output size falls within 0 to 8 mm. Due to the special rotor design and its minimal distance from the anvils, the sand production rate in this machine is significantly higher than in other types of impact crushers.

On average, approximately:

- 70% of the machine’s output consists of crushed sand with a size of 0-6 mm.

- 25% of the final product consists of pea-sized and almond-shaped aggregates.

- The remaining 5% includes larger particles that need to be recirculated back into the machine for further crushing.

Advantages of the Double-Sided Sand Maker

One of the key advantages of the Double-Sided Sand Maker compared to other types of crushers is its high fine material production, making it ideal for producing crushed sand. This machine is highly suitable for crushing materials to sizes smaller than 15 mm. However, if the input materials contain high amounts of silica, it is not recommended to use this machine, as it may lead to increased maintenance and repair costs due to rapid wear of components.

The efficient performance of this machine is due to the high rotor speed and minimal distance between the rotor and the anvils, which increases the impact intensity and enhances the crushing process. Additionally, to prolong the machine’s lifespan and reduce maintenance costs, all wear parts, including hammers, anvils, and linings, are cast from alloy steel and cast iron with low wear rate and typically feature multiple usable edges.

Key Features of the Double-Sided Sand Maker:

✅ Production Capacity: 60 tons per hour

✅ Output Material Volume: 70% crushed sand with a 0-6 mm size

✅ Design: Two anvils on both sides with a minimal gap between the rotor and anvils

✅ Application: Suitable for crushing hard rocks and soft stones

✅ Performance: Enhanced impact force between hammers and anvils for efficient crushing

✅ Durability: Wear-resistant components with long service life

Due to its high efficiency and specialized design, this machine is an excellent choice for producing high-quality sand with optimal grain size distribution in sand and gravel mines.

Components of the Double-Sided Sand Maker

All manufacturing processes for the components of the double-sided sand maker, including hammers, anvils, and other parts, are supervised by Avangard’s expert technical team, graduates from top universities in Iran and Canada, ensuring that the quality of these parts meets the highest standards and extends the device’s lifespan. This precise supervision ensures that the produced parts have outstanding features such as high wear resistance and long service life.

The double-sided sand maker, recognized as one of the essential tools in the rock crushing process in mines and the production of crushed sand, consists of a series of specialized components. These parts, working in harmony and proper functioning, facilitate the crushing and transformation of input rocks into high-quality sand with specific dimensions. Below, we will introduce the components of this device and their function.

Some of the key components of the double-sided sand maker include the main frame, rotor, hammers, anvils, impactor bars, side liners, shaft, electric motor, bearings, and liners. Each of these parts plays a critical role in the device’s performance and can significantly impact the quality and efficiency of the crushing process.

Main Frame

The main frame, as the structural part of the device, is robust and heavy-duty. This part supports all the other components of the machine and ensures that other parts operate under optimal conditions.

Rotor

The rotor of the double-sided sand maker is a key component that provides the energy necessary for crushing rocks. The rapid movement of the rotor causes the rocks to strike the hammers and break. The high speed of the rotor increases the intensity of the impact and, as a result, the production of more sand.

Hammers

The hammers (impact hammers) are one of the main wear parts of the device and wear out due to impacts with the rocks. These sensitive and abrasive parts are made of specific materials that significantly increase the device’s useful life. In Avangard’s casting process, the hammers are made from alloys like manganese steel, manganese steel with 0.5% molybdenum, Ni-Hard4 iron, and high chromium cast iron. These alloys, in addition to high strength, provide excellent wear and erosion resistance, reducing breakdowns and frequent repairs over time.

Anvils

Anvils act as the second impact surface in the double-sided sand maker, absorbing excess energy after the rocks collide with the hammers to complete the crushing process. Like hammers, anvils wear out after prolonged use and need to be replaced. At Avangard, anvils are made from alloys such as manganese steel, manganese steel with 0.5% molybdenum, Ni-Hard4, and high chromium cast iron. The use of these abrasion- and heat-resistant alloys increases the lifespan of the anvils and prevents premature wear.

Impactor Bars

Impactor bars serve as protective layers and are responsible for holding the anvils in place.

Side Liners

The side liners, which are located next to the rotor, are responsible for protecting the body of the device from wear and direct impact with the rock materials. This part is crucial for reducing damage and ensuring optimal maintenance of the machine.

Shaft

The shaft, as a pivotal part, connects the rotor and other components of the device. This part must be made from durable materials and with high precision to withstand the forces exerted during the crushing process.

Electric Motor

The electric motor provides the necessary power to drive the device. Choosing an appropriately powered motor is essential for ensuring that the rotor operates efficiently and optimally.

Bearings

Bearings play a critical role in reducing friction and ensuring smooth movement of the shaft and rotor. Selecting high-quality bearings increases the machine’s lifespan and reduces the need for frequent repairs.

Liners

Liners are used to protect the body of the device from wear and damage caused by contact with rock materials. These parts must be made of durable and high-strength materials to extend the machine’s lifespan.

Potential Damages and Their Impact

Given that the double-sided sand maker operates continuously over time and is exposed to wear and tear, parts such as hammers, covers, and anvils may experience damage after a certain period. The failure of these parts can significantly affect the machine’s performance and lead to reduced efficiency or even halt operations. Therefore, timely inspection and repair or replacement of wear parts, such as hammers and anvils, is crucial.

Using high-quality parts, especially in wear components like hammers, anvils, and covers, can significantly reduce the failure and wear of the machine. By using high-quality crusher parts produced by Avangard, one can save on maintenance and repair costs while extending the machine’s useful life.

As a result, paying attention to the selection and maintenance of the appropriate and high-quality parts for the double-sided sand maker can have a significant impact on reducing costs and improving production efficiency.

Applications of the Double-Sided Sand Maker

The double-sided sand maker is used in various industries such as asphalt production, road construction, and concrete pouring. This device helps construction processes by converting large stones into sand sized 0 to 8 millimeters. The production capacity of this machine is 60 tons per hour, and with its dual-sided design featuring anvils on both sides, it provides better performance compared to conventional machines. This feature increases collisions and consequently produces more sand. About 70% of the output of this machine is crushed sand, while the remaining 25% is produced in pebbly and almond shapes. The double-sided sand maker is suitable for crushing mountain rocks, soft stones, and minerals like gypsum and limestone, but it is not recommended for materials with high silica content, as it will increase maintenance costs.

Types of Double-Sided Sand Makers

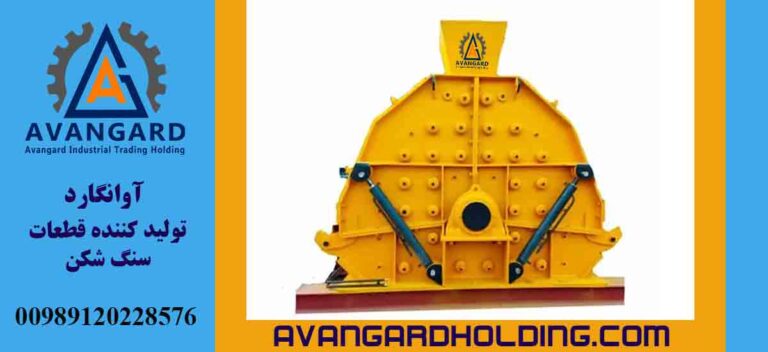

The double-sided sand maker comes in two types: hydraulic (with jacks) and simple (without jacks). Depending on the customer’s needs and requests, these can be bought and sold at different prices. The installation of jacks on the side doors of the sand maker is done upon customer request to improve machine performance.

This machine, recognized as a type of crusher from the impact crusher family, is designed and manufactured by Avangard Holding in two models: four-hammer and six-hammer versions. The crushing principles in the double-sided sand maker are similar to the crushing process in impact crushers, but with specific optimizations to increase sand production and improve grading quality. These changes mainly relate to the performance of the hammers, such that by removing large loads from the bottom of the machine and re-impacting, the return material is reduced, and sand production is increased.

The double-sided or pocket sand maker is specifically designed to improve the grading process in mines and is used as one of the main machines for producing high-quality sand with appropriate sizes for use in construction and civil engineering projects. This device is used in various projects such as asphalt production, concrete pouring, and road construction. Due to its unique features, it can meet various needs in these industries.

Operation and Performance of the Double-Sided Sand Maker

The double-sided sand maker, with its unique design and the ability to rotate both clockwise and counterclockwise, is highly effective for crushing and producing high-quality sand in various industries. This device consists of a rotor that includes hammers, a cover, and a magazine, and operates at a speed of 980 revolutions per minute. In this process, the input materials collide with the rotor and hammers, and then they hit the body and walls of the machine, which are equipped with durable anvils, and are crushed. This crushing process ultimately results in the production of sand and fine particles.

One of the prominent features of the double-sided sand maker is its ability to adjust the sand output. The device can control the size of the produced sand by adjusting the anvils. Additionally, the machine has anti-wear shields inside, which act as barriers to prevent damage to the internal parts of the machine. The input materials are crushed into fine particles when they collide with the blades and rotor, which have speeds ranging from 15 to 50 meters per second.

The double-sided sand maker is available in two models: hydraulic (with jacks) and simple (without jacks), and you can purchase the one that suits your needs. Avangard offers this machine with a production capacity of 70 tons per hour, with 40% of the output being sand with a size of 0 to 6 millimeters.

This device operates similarly to impact crushers but with the difference that it has anvils on both sides, and the rotor’s distance from these anvils is very small. This feature increases collisions, resulting in more sand and fine particles being produced. Depending on customer needs, the double-sided sand maker can be produced with or without jacks, allowing customers to easily choose the version that suits them best.

Given the high speed of the rotor and the optimized performance of this machine in crushing materials, the double-sided sand maker is one of the best choices for industries such as asphalt production, concrete pouring, and road construction that require the production of high-quality sand.

Advantages and Disadvantages of the Double-Sided Sand Maker

The double-sided sand maker is one of the key pieces of equipment in the construction and mining industries, used for crushing and producing sand from soft and semi-hard minerals. While this device offers several advantages, it also has some disadvantages, which are discussed below.

Advantages of the Double-Sided Sand Maker:

- High Efficiency in Sand Production: The double-sided sand maker is capable of producing approximately 60 tons of sand per hour, which is higher than some similar devices.

- Product Quality: The final product of this machine has a broken and sharp grain structure, which is highly useful in road construction, concrete production, and building construction.

- Ability to Use Both Sides of the Machine: One of the standout features of the double-sided sand maker is its ability to alternate use of both sides of the device, reducing wear and increasing its useful life.

- Ability to Crush Wet Materials: Unlike some sand makers that face issues when dealing with wet materials, the double-sided sand maker can work efficiently with moist materials, reducing the risk of clogging or damage to the machine shaft.

- Larger Input Load Size: This machine can process stones up to a maximum size of 150 mm, which is an advantage compared to some other sand makers, whose maximum input load size is 70 mm.

Disadvantages of the Double-Sided Sand Maker:

- Limitations in Crushing Hard Stones: The double-sided sand maker is designed for crushing soft and semi-hard stones, and using it for hard rocks results in higher wear and tear, which increases maintenance costs.

- Lack of Hydraulic System in Some Models: Some models of the double-sided sand maker do not have a hydraulic system to adjust the equipment, making the adjustment process more difficult and time-consuming.

Given the advantages and disadvantages mentioned, the choice of a double-sided sand maker should be made considering the specific needs and conditions of the project to achieve optimal performance and efficiency.

Maintenance of the Double-Sided Sand Maker

The maintenance and repair of double-sided sand makers are crucial in ensuring optimal performance and extending the lifespan of these machines. These devices, which play a key role in the crushing and screening of minerals in mines, require regular servicing and specialized repairs.

Skilled technicians at Avangard Holding, utilizing technical expertise and practical experience, offer maintenance and repair services for various sand makers and crushing equipment. These services include inspection and replacement of worn-out parts, precise mechanical and electrical adjustments, and ensuring the correct functioning of the machines. Timely repairs and the use of high-quality spare parts can prevent unexpected breakdowns and enhance the efficiency of mining operations.

Avangard Holding focuses on providing excellent after-sales services, ensuring that clients’ equipment is always in optimal operational condition. This not only helps reduce unexpected repair costs but also increases the efficiency and useful life of double-sided sand makers.

Specifications of the Double-Sided Impact Crusher (Double-Sided Sand Maker or Pocket Sand Maker)

The double-sided impact crusher, also known as the double-sided sand maker or pocket sand maker, is one of the most widely used machines in sand and gravel production lines and mineral processing. This device is used for crushing soft and semi-hard rocks such as mountain stones, limestone, and dolomite and is capable of producing high-quality sand.

Technical Specifications and Performance of the Double-Sided Impact Crusher

The double-sided sand maker can crush stones with an input size ranging from 0 to 150 millimeters and deliver the final product within a particle size range of 0 to 8 millimeters to the consumer. This machine is equipped with wear-resistant hammers, which feature 3 grooves and 6 usable edges, allowing for up to 80% capacity utilization of the hammers. This results in increased part lifespan and reduced maintenance costs.

Production Capacity and Efficiency

One of the standout features of the double-sided sand maker is its high production capacity. This machine is capable of producing 60 tons of sand per hour, which is a higher output compared to other similar models.

Difference Between Double-Sided and Regular Impact Crushers

In this machine, the presence of anvils on both sides increases the crushing efficiency. Additionally, the rotor-to-anvil distance in this model is shorter than in a regular impact crusher, which leads to more material collisions and consequently, a higher sand production rate.

Rotor Specifications and Structural Design

The rotor of the double-sided sand maker is equipped with 3 or 4 rotor arms made of 60-millimeter thick wear-resistant blades. The precise design and proper balancing of this rotor enhance efficiency and reduce part wear, ensuring optimal performance under heavy-duty operating conditions.

These features make the double-sided impact crusher an ideal choice for sand and gravel quarries and construction material production plants.

Buy Double-Sided Sand Maker – A Reliable Choice for High-Quality Sand Production

The double-sided sand maker (Double-Sided Impact Crusher) is an essential piece of equipment in the mining industry and sand production. With its special design, optimized performance, and high production capacity, it is an ideal choice for quarries. This machine uses wear-resistant hammers and an impact system to convert incoming rocks into sand with a standardized particle size, enhancing the efficiency of production lines. Avangard’s Double-Sided Sand Maker features hammers with 6 usable edges, a production capacity of 60 tons per hour, and double-sided anvils to increase crushing efficiency. The price of this device varies depending on technical specifications, component materials, and the manufacturer. To purchase a double-sided sand maker and receive expert consultation, current price inquiries, and order placement, you can contact Avangard Crusher experts and benefit from professional after-sales services.

Sale of Double-Sided Sand Maker – The Best Choice for Producing Standard Sand

The double-sided sand maker (Double-Sided Impact Crusher) is one of the most widely used crushing equipment in sand and gravel quarries, designed to produce high-quality, uniform sand. This machine operates similarly to rock-and-rock sand makers and rabbit-type sand makers in fine material production processes. It features wear-resistant, replaceable hammers with 6 usable edges, double-sided anvils to enhance crushing, and a powerful rotor to maximize production efficiency.

Avangard Crusher, a trusted supplier of crushing and grading equipment, offers competitive prices and guaranteed quality for the sale of double-sided sand makers. For specialized consultation, technical specifications review, and order placement, feel free to contact our experts and take advantage of our professional after-sales services.

Price of Double-Sided Sand Maker – Influencing Factors and Buying Guide

The price of a double-sided sand maker (Double-Sided Impact Crusher), also known as the pocket sand maker or double-sided impact crusher, is influenced by various factors such as material quality, the number of hammers, production capacity, and the manufacturer’s brand. The more wear-resistant hammers and durable anvils the machine has, the higher its power and efficiency, which in turn raises its price. Additionally, using high-quality alloys in the construction of the body and internal parts increases the machine’s lifespan and reduces maintenance costs.

Various models of sand makers, such as the Hydrocone machine, double-sided impact sand maker, rock-and-rock sand maker, and rabbit-type sand maker, are available in the market at different prices. Avangard Crusher, as a reputable supplier of crushing equipment, offers the best prices relative to quality. To inquire about the latest prices, receive expert consultation, and purchase a device suitable for your needs, contact our experts.

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.