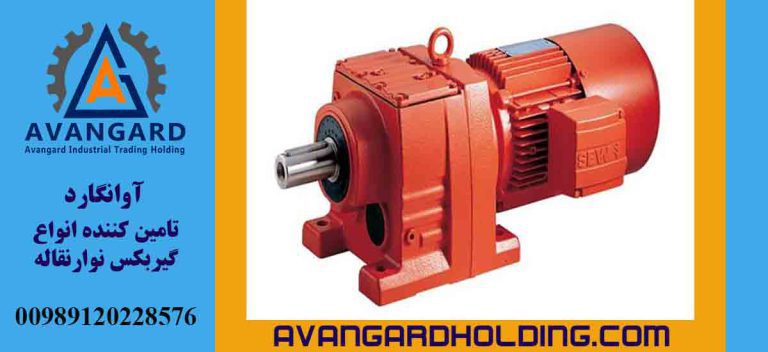

Conveyor Gearbox

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

Conveyor Gearbox: Applications and Benefits

The conveyor gearbox is a key component in material handling systems, playing a crucial role in many industries due to its unique design and performance capabilities. These gearboxes are used to convert and control motor speed and transmit mechanical power to conveyor belts. By using a conveyor gearbox, the speed of the belt can be accurately adjusted, and the required torque for transporting various materials can be provided.

Selecting the most suitable conveyor gearbox requires a thorough review of gearbox prices and the various types available. Conveyor gearboxes and motor gearboxes are specifically designed to enhance conveyor performance and are available in different types in the market. Referring to the Avangard conveyor gearbox catalog can greatly assist in familiarizing yourself with the features of each model before making a purchase. Additionally, the relationship between the conveyor motor and gearbox plays a key role in the efficiency of industrial transport systems. With the right choice, you can significantly improve the efficiency and durability of your conveyor system.

Applications of Conveyor Gearboxes:

- Manufacturing and Packaging Industries: In production and packaging lines, conveyor gearboxes are used to transport products through various stages of the production and packaging process. These gearboxes adjust the belt speed and ensure continuous and uninterrupted material transfer.

- Food Industry: In this industry, conveyor gearboxes are used for raw material transport, packaging, and other processes. The hygienic design and cleanability of these gearboxes are of particular importance.

- Mining and Construction Industries: In mines and construction sites, conveyor gearboxes are employed to transport rocks, soil, and other heavy materials. Their high power and durability in harsh environments make them highly valuable.

Benefits of Conveyor Gearboxes:

- Accurate Speed and Torque Control: Conveyor gearboxes allow for precise adjustment of the belt speed and torque, contributing to improved system performance and increased production line efficiency.

- Extended Equipment Life: With their robust design and high power, conveyor gearboxes can withstand heavy loads and pressures, thus extending the lifespan of conveyor systems.

- Energy Efficiency: Modern, high-quality gearboxes are optimized to reduce energy consumption and enhance material handling system efficiency.

- Noise and Vibration Reduction: Many conveyor gearboxes are designed to minimize noise and vibrations during operation, creating a quieter work environment.

By choosing and using the right conveyor gearbox, production line efficiency can be significantly increased, ensuring stable and effective material transfer systems.

Various Types of Gearboxes Used in Conveyors

In conveyor systems, choosing the right type of gearbox is crucial for optimizing performance and efficiency. Each type of gearbox has its own features and applications, as described below:

Helical Gearbox:

Helical gearboxes, with their spiral gears and specific design, are highly suitable for the transmission of power and torque to conveyor belts. The increased tooth contact results in smooth and quiet operation, making them commonly used in various industries such as manufacturing and packaging.

Worm Conveyor Gearbox:

Worm gearboxes, characterized by their unique design with worm gears and screws, are used for speed reduction and increased torque. Their compact design and high power make them ideal for confined spaces and heavy load transportation, such as in the food and packaging industries.

Bevel Gearbox:

Bevel gearboxes, also known as parallel shaft gearboxes, are capable of changing the direction of movement and transmitting power at various angles. These gearboxes are useful in applications like elevators and cranes and are suitable for conveyors needing directional changes.

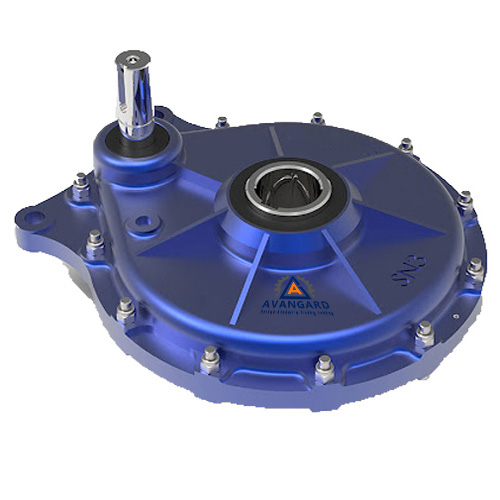

Planetary Conveyor Gearbox:

Planetary gearboxes, known for their specific design, provide high power and torque with high efficiency. These gearboxes are used in conveyor systems requiring large-scale power transmission with precise accuracy, especially in heavy industries and robotics.

Cycloidal Gearbox:

Cycloidal gearboxes, with their distinctive cycloidal gears, are highly suitable for applications requiring high precision and large torque. Their high gear ratio and compact design make them ideal for conveyors requiring minimal space and weight, used in automotive and heavy machinery industries.

Selecting the right type of gearbox for the conveyor can ensure optimal performance and high efficiency in material transfer systems.

Guide to Choosing a Gearbox for Conveyors: Key Points and Recommendations

Choosing the right gearbox for the conveyor significantly impacts the performance and efficiency of the material handling system. Here are key points and important recommendations for selecting the appropriate gearbox for your conveyor:

- Load and Torque Specifications:

One of the first and most important steps in selecting a gearbox is determining the conveyor’s load and torque needs. Calculate how much load your conveyor will carry and the required torque to move the belt. The selected gearbox must meet these needs without overloading or damage.

- Conveyor Speed:

Conveyor speed is another crucial factor. Depending on the process needs, the conveyor speed should be accurately adjusted. The gearbox must provide the desired speeds while maintaining system efficiency.

- Type of Movement and Direction Changes:

In some applications, changing the direction of the conveyor or adjusting to different speeds is essential. For such applications, bevel or planetary gearboxes capable of direction change are more suitable. Assessing the need for direction change and variable speeds can help in selecting the right gearbox.

- Working Environment and Operational Conditions:

Environmental and operational conditions such as temperature, humidity, and the presence of chemicals or dust can significantly impact the gearbox’s lifespan. The gearbox should be resistant to specific environmental conditions and well-protected to ensure optimal performance and longer service life.

- Space and Dimensions:

The design and dimensions of the gearbox must match the available installation space. Worm and planetary gearboxes are usually suitable for confined spaces, while helical and bevel gearboxes may require more space.

- Quality and Brand:

Choosing a gearbox from reputable and high-quality brands can reduce the need for repairs and maintenance and increase the gearbox’s lifespan. Checking user reviews and consulting experts can help in selecting the right brand.

- Cost and Budget:

Finally, the budget for purchasing a gearbox should be considered. Comparing prices and features of different gearboxes can help find the best option according to technical and financial needs.

By following these tips and recommendations, you can select the right gearbox for your conveyor and benefit from optimal and stable material handling system performance.

Comparing Different Gearboxes for Conveyors: Which One is Best?

When choosing the appropriate gearbox for conveyors, it is important to carefully review the types and features of different gearboxes to select the best option. Below is a comparison of various gearboxes for conveyors to help you make a better decision:

- Helical Gearbox:

- Features: Helical gearboxes with their spiral teeth offer smooth and quiet operation. These gearboxes are suitable for medium loads and constant speeds, and due to increased tooth contact, they have high efficiency.

- Advantages: Noise reduction, increased efficiency, and long lifespan. Ideal for industrial conveyors requiring continuous and uninterrupted performance.

- Disadvantages: Requires more installation space and may not be suitable for directional changes.

- Worm Gearbox:

- Features: Worm gearboxes are compact and highly capable of speed reduction and increased torque. These gearboxes are suitable for heavy loads and confined spaces.

- Advantages: Compact design, high power, and capability to be installed in limited spaces. Ideal for conveyors requiring speed reduction and increased torque in small spaces.

- Disadvantages: May have lower efficiency compared to other types of gearboxes and may not withstand high pressures.

- Bevel Gearbox:

- Features: Bevel gearboxes can change the direction of movement and adjust to different speeds. These gearboxes are suitable for applications requiring directional changes or speed adjustments.

- Advantages: Ability to change direction and adjust speed, suitable for conveyors needing frequent directional and speed changes.

- Disadvantages: May have higher costs and dimensions compared to other types of gearboxes.

- Planetary Gearbox:

- Features: Planetary gearboxes, with their specific design, provide high power and torque with high efficiency. These gearboxes are suitable for conveyors requiring large-scale power transmission with high precision.

- Advantages: High efficiency, large torque, and long lifespan. Best option for heavy conveyors and complex industrial systems.

- Disadvantages: Higher costs and the need for expertise in selection and installation.

- Cycloidal Gearbox:

- Features: Cycloidal gearboxes with their unique design and high gear ratio are suitable for applications requiring high precision and large torque. These gearboxes are usually used in conveyors requiring precision and minimal space.

- Advantages: Compact design, high gear ratio, and ability to provide high precision and torque.

- Disadvantages: May have higher costs and require specific maintenance.

Selecting the best gearbox for the conveyor depends on the specific system needs and work environment. Helical gearboxes are suitable for quiet and stable operation, while worm gearboxes are efficient for confined spaces and heavy loads. Bevel gearboxes are useful for directional changes and speed adjustments, planetary gearboxes are best for high power and heavy-duty conveyors, and cycloidal gearboxes are ideal for precision and limited spaces. By considering your specific needs, you can choose the best option to achieve optimal performance and high efficiency in your conveyor system.

Maintenance Tips for Conveyor Gearboxes for Optimal Performance

For maintaining the optimal performance of conveyor gearboxes, adhering to essential maintenance and repair tips is crucial. The first step is conducting regular inspections to check oil levels, gear, and shaft conditions, as neglecting these aspects can lead to faster wear and failure. Timely oil changes and using the appropriate type prevent overheating and reduce friction. Regularly checking and adjusting belt and power transmission systems prevent unnecessary tensions and potential damages. Regular cleaning, temperature control, and proper washing prevent dust and contamination buildup. By following these guidelines, the gearbox lifespan can be increased, and significant problems and additional repair costs can be avoided.

Reputable Conveyor Gearbox Brands in the Market: Introduction and Review

In the conveyor gearbox market, choosing a reputable brand can ensure quality, stable performance, and long equipment life. Leading brands in this sector include SEW-EURODRIVE, Bonfiglioli, Nord Drivesystems, and Boston Gear. SEW-EURODRIVE, with its advanced designs and innovative technologies, is one of the popular brands in the industry known for its high quality and reliable performance. Bonfiglioli, with a wide range of efficient gearboxes, is especially noted for heavy applications. Nord Drivesystems is recognized as a market leader due to its durability and high efficiency, while Boston Gear is a reliable choice for various industries, offering high-quality products and excellent after-sales service. Reviewing and comparing these brands based on specific project needs can help in making an optimal choice and enhancing conveyor efficiency.

Conveyor Gearbox Price List

For Avangard’s customers, knowing the conveyor gearbox price list is particularly important as this information can help in making informed decisions when selecting the right equipment. Avangard offers a wide range of conveyor gearboxes from reputable and high-quality brands, with prices varying based on technical specifications, size, and application. Prices may be influenced by factors such as the type of gearbox (helical, worm, bevel, etc.), load capacity, speed, and specific features. To obtain detailed and up-to-date prices, customers can contact Avangard sales experts for consultation to make the best choice according to their specific project needs.

| No. | Product Description | Price |

| 1 | Flender Conveyor Gearbox Price | Contact |

| 2 | SEW Conveyor Gearbox Price | Contact |

| 3 | Worm Conveyor Gearbox Price | Contact |

| 4 | Helical Conveyor Gearbox Price | Contact |

| 5 | Bevel Gearbox Price | Contact |

| 6 | Planetary Conveyor Gearbox Price | Contact |

| 7 | Hanging Conveyor Gearbox Price | Contact |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.