Conveyor Belt Magnet

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

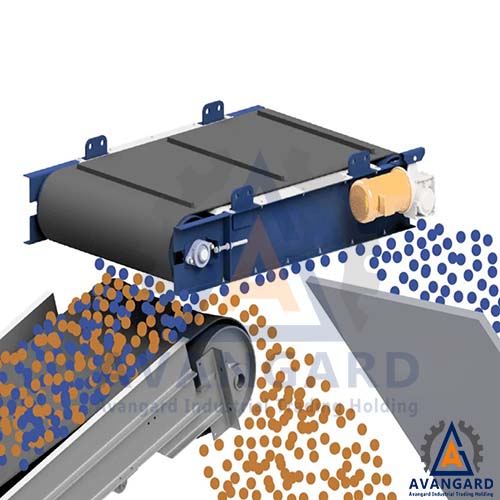

What is a Conveyor Belt Magnet?

In various industries including sand and gravel mining, steel, and recycling, the presence of metallic waste in raw materials is a significant challenge. This metallic waste can damage industrial machinery, including crushers, reducing production efficiency. The conveyor belt magnet uses a strong magnetic force to separate metal particles from materials, preventing them from entering subsequent processing stages. Different types of these devices, such as permanent belt magnets and overband separators, available as self-cleaning and manual models, are available in the market. Conveyor magnets are installed suspended over the conveyor belt, separating metals and preventing machinery breakdowns and production halts. Using these devices also increases machinery lifespan and enhances overall production efficiency.

If you are looking to purchase or inquire about the price of a conveyor belt magnet, various options are available, including second-hand conveyor magnets, which may be more cost-effective. To obtain these products, you can consult with Avangard, a reputable supplier and manufacturer of magnets and industrial magnets. Additionally, magnet sales in Tehran offer various kinds of conveyor magnets and magnetic separators to meet the needs of different industries.

Features of Conveyor Belt Magnet

The conveyor belt magnet, with features such as iron waste separation from materials, increasing machinery lifespan, and preventing equipment breakdowns, plays a crucial role in improving industrial processes. Permanent and electromagnetic magnets, each having their unique advantages and applications, are used in these systems.

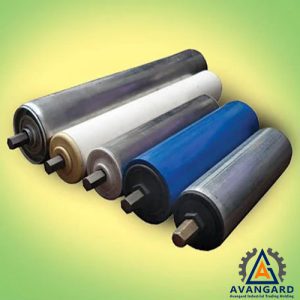

A magnetic or magnetized conveyor belt is a system that, in addition to transporting materials, can separate metal parts from other materials. The device derives its name from the Latin word Magnet, meaning magnet, describing its magnetic feature. The magnetic conveyor belt uses strong magnetic forces to attract and separate metals, directing them along a specific path. This type of belt conveyor is widely used in industries such as mining, recycling, and automotive parts production.

Types of Conveyor Belt Magnets

Manual Overband Separator Magnet

These magnets are used for separating small to medium-sized iron parts in production lines. Their operation involves manual removal of metallic pieces such as screws, belts, and other iron waste by an operator. These magnets are typically used where the volume of iron waste is smaller and manual intervention for separation is necessary. They serve as a safety tool to prevent disruptive metal pieces from entering sensitive machinery like crushers and mills.

Automatic Overband Separator Magnet

These magnets are connected to an automatic conveyor system that separates iron waste from the production line without human intervention, directing it outside the material flow. One advantage of these magnets is the elimination of operator errors and improved production efficiency. Automatic magnets operate continuously and without interruption, reducing the need for frequent cleaning stops, thus increasing plant productivity. These systems are mainly used in industries with high production volumes and sensitivity to stoppages.

Suspended Conveyor Belt Magnet

The suspended conveyor belt magnet is installed above the conveyor belt and uses strong magnetic forces to separate metallic particles from moving materials. Due to its specific installation position, this type of magnet is highly effective at separating unwanted metals and preventing damage to sensitive equipment like crushers, presses, and mills. Considering the suspended magnet requires specific installation space, it should be used in production lines where top installation is feasible.

Permanent Belt Magnet

These magnets are of the permanent type and are used for continuous iron waste separation without the need for electricity. The self-cleaning operation of the permanent belt magnet separates metallic waste continuously from passing materials and directs it out of the production line. A major advantage of these magnets is that they do not require complex maintenance or the use of electrical energy sources.

Belt and Manual Overband Separator Magnet

These two types of magnets are used in production lines for separating metal parts from raw materials like loader nails, iron belts, chute components, and screens. Their operation is such that they separate metal waste either manually or automatically from underneath passing materials. Belt and manual magnets not only prevent production halts and financial loss from metal entry into machinery but also extend the equipment’s lifespan.

Electromagnetic and Permanent Magnet

Separator magnets are divided into **electromagnetic** and **permanent** types. Electromagnetic magnets work using coils and electricity and are cooled using oil. Conversely, permanent magnets use natural magnets and do not require electricity. Both types of these magnets are used depending on the production line’s needs and the volume of iron waste, with the selection based on energy costs and magnetic power requirements.

Choosing Between Types of Magnets

Separator magnets are essential tools in production lines that enhance productivity, reduce unexpected stoppages, and prevent damage to expensive machinery by separating iron waste from passing materials. The choice between manual, automatic, suspended, and belt magnets depends on production volume, the type of passing materials, and the need for metal separation.

Applications of Conveyor Belt Magnet

Conveyor belt magnets are used in numerous industries including mining, steel, recycling, food, and chemicals. This device prevents metal parts from moving materials from entering sensitive production stages. The suspended conveyor belt magnet is especially effective for the automatic separation of iron waste. Various industries like copper, lead and zinc, foundry, waste management, chipboard and paper, sand and gravel, tile and ceramics, plaster and lime, cement, glass and silica, copper and aluminum, sugar, petrochemicals, organic fertilizers, recycling, and the chemical and refractory industries benefit from this technology.

Advantages of Using Conveyor Belt Magnets

- Removal of iron waste from the production line

- Protection of production line equipment (such as crushers, mills, presses, etc.)

- Increased lifespan of production line equipment

- Long device lifespan

- Very low wear

- Separation of iron parts from raw materials and increased material purity

- Protection of equipment such as crushers (cubic, hydrocone, jaw), mills, presses

Table of Types of Conveyor Belt Magnets

| No. | Magnet Type | Main Application | Advantages | Disadvantages | Important Notes |

| 1 | Self-Cleaning Conveyor Belt Magnet | Separation of metal particles from non-metal materials in flow | Easy cleaning, high efficiency, suitable for heavy flows | Higher cost, more complex installation | Select suitable coating to prevent corrosion |

| 2 | Suspended Over Conveyor Belt Magnet | Separation of large metal particles from non-metal materials | Easy installation, less expensive than other types, suitable for large particle materials | Less magnetic force than other types, requires more space | Suitable for low-density materials |

| 3 | Permanent Conveyor Belt Magnet | Permanent separation of metal particles, no electricity needed | Low maintenance cost, high efficiency in harsh environments | Fixed magnetic power, no power adjustment possible | Suitable for fixed and permanent applications |

| 4 | Overhead Conveyor Belt Magnet Separator for Cement Industry | Separation of metal particles from cement raw materials | Prevents equipment damage, increases product quality | Requires periodic maintenance, high initial cost | Suitable for industries with high production volume |

| 5 | Overhead Conveyor Belt Magnet Separator for Recycling Industry | Separation of ferrous metals from recyclable materials | Increases recyclables value, reduces environmental pollution | Requires initial separation of materials, possible non-magnetic materials | Suitable for different types of recyclable materials |

| 6 | Magnetic Head Pulley Separator | Separation of very fine metal particles from fluids | High efficiency in fine particle separation, long lifespan | High cost, requires precision in installation and adjustment | Suitable for pharmaceutical, food, and chemical industries |

| 7 | Electric Conveyor Belt Magnet | Separation of metal particles with power control | High flexibility in power adjustment, suitable for materials with different magnetic properties | Requires power supply, higher maintenance cost | Suitable for applications needing magnetic power adjustment |

| 8 | Magnetic Drum Separator | Separation of metal particles from dry and powdery materials | High efficiency, high capacity, suitable for low moisture materials | High initial cost, requires more space | Suitable for mineral and material processing industries |

Purchasing Conveyor Belt Magnet

To purchase a conveyor belt magnet or, in other words, buy a conveyor magnet and types of overband or magnetic separators, you can contact the sales experts at Avangard Company. This company provides high-quality products and free consultation to help you select the best equipment.

Conveyor Belt Magnet Sales

Avangard Company is one of the leading suppliers of conveyor belt magnets. Based on your needs, the company offers a diverse range of products including suspended conveyor magnets, belt magnets, and other types of magnetic conveyor parts. For information on sales terms and consultation, contact the Avangard conveyor belt magnet sales experts.

Conveyor Belt Magnet Price

The price of conveyor belt magnets depends on factors such as magnet type, magnetic strength, size, and brand. For exact pricing and free consultation, you can contact Avangard Company’s sales experts.

| No. | Product Description | Price |

| 1 | Price of Magnetic Separator | Contact us |

| 2 | Price of Overbelt Magnet | Contact us |

| 3 | Price of Overband Magnet | Contact us |

| 4 | Price of Overband Magnetic | Contact us |

| 5 | Price of Magnetic on Conveyor Belt | Contact us |

| 6 | Price of On Belt Magnet | Contact us |

| 7 | Price of Magnetic Separator | Contact us |

| 8 | Price of Magnet Separator | Contact us |

| 9 | Price of Magnet Box | Contact us |

| 10 | Price of Second-Hand Conveyor Belt Magnet | Contact us |

| 11 | Price of Conveyor Belt Magnet | Contact us |

| 12 | Price of Conveyor Belt Magnet Separator | Contact us |

| 13 | Price of Magnetic Magnet | Contact us |

| 14 | Price of Self-Cleaning Conveyor Belt Magnet | Contact us |

| 15 | Price of Suspended Over Conveyor Belt Magnet | Contact us |

| 16 | Price of Permanent Conveyor Belt Magnet | Contact us |

| 17 | Price of Overhead Conveyor Belt Magnet Separator for Cement Industry | Contact us |

| 18 | Price of Overhead Conveyor Belt Magnet Separator for Recycling Industry | Contact us |

| 19 | Price of Magnetic Head Pulley Separator | Contact us |

| 20 | Price of Electric Conveyor Belt Magnet | Contact us |

| 21 | Price of Drum Magnetic Separator | Contact us |

| 22 | Price of Permanent Overbelt Magnet | Contact us |

| 23 | Price of Overband Magnet Separator | Contact us |

| 24 | Price of Magnet Separator | Contact us |

| 25 | Price of Magnet Drum | Contact us |

| 26 | Price of Manual Overband Separator Magnet | Contact us |

| 27 | Price of Automatic Overband Separator Magnet | Contact us |

| 28 | Price of Suspended Conveyor Belt Magnet | Contact us |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.