Fixed and Movable Conveyor Roller

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

What is Fixed and Movable Conveyor Roller?

Fixed and movable conveyor rollers (conveyors) are vital components in material transfer and handling systems, playing a key role in the proper and efficient operation of conveyor belts. These rollers, also known as “fixed rollers” and “movable rollers” or drums, are used in industries such as mining, cement, steel, and other heavy industries. Conveyor rollers are designed and manufactured in two types: fixed rollers and movable rollers, each having specific tasks. Fixed rollers are responsible for maintaining and supporting the conveyor belt and are often used in areas of the conveyor where there is no need to change the direction of movement due to their simpler and more stable structure. On the other hand, movable rollers with adjustable angle capabilities are very suitable for areas where there is a need to change direction or adjust belt tension. Correctly selecting and purchasing high-quality rollers can have a direct impact on the equipment’s lifespan and reduce maintenance costs. For purchasing rollers, knowing roller prices, and seeking advice on the appropriate rollers for your industrial needs, contact Avangard’s sales experts to benefit from the company’s specialized services.

Avangard Industrial Trading Holding, with over two decades of valuable experience, is ready to provide services in consulting, design, manufacturing, and production of material transfer equipment and automation. The company also offers the best price for rubber conveyor roller (drum).

One of the most important parts of this industry is the drum roller or pulley. The drum, also known as the conveyor belt roller, is one of the main components of conveyor belts. The belt (Belt) of the conveyor is placed around the drum at the beginning and end of the conveyor. The starting drum is known as the driving drum (Head Pulley) and the ending drum is known as the movable drum (Tail Pulley).

Types of Rollers in Conveyors and Their Applications

Tension Roller

The tension roller is an essential component in conveyor systems responsible for adjusting the tension of the conveyor belt. This roller applies the appropriate force to the belt to prevent excessive slackness or tension. Correct belt tensioning not only increases the lifespan of the belt and rollers but also improves the overall system performance and reduces the likelihood of technical issues.

Idler Roller

Idler rollers act as the primary support for the conveyor belt, preventing it from bending or being damaged along the way. These rollers help with the smooth and uninterrupted movement of the belt by reducing friction between the belt and the surface. The material, dimensions, and number of idler rollers vary depending on the belt type, bearing capacity, and working conditions of the system.

Drive Roller

The drive roller provides the main driving force for the conveyor belt. It is typically connected to the drive motor and, through its rotation, moves the belt. Drive rollers are usually made from steel with wear-resistant coatings to withstand the forces applied. The choice of drive roller type depends on various factors, including load capacity, belt speed, and the type of materials being transported.

Types of Drums Based on Shaft

Drum with Welded Shaft

Drums with welded shafts are used in conveyors with a belt length of less than 30 meters, particularly in light industries. In such drums, if the shaft is damaged, there is no choice but to replace the entire drum. The thickness of the pipe in welded shaft drums usually ranges from 8 to 10 millimeters. The diameter of drum shafts varies relative to the diameter of drum pipes, belt width, length, and capacity.

Drum with Replaceable Shaft

In conveyors longer than 30 meters, especially in steel and cement factories, drums with replaceable shafts and standard locks are used. A major advantage of these drums is that if the shaft is damaged, it can be replaced, and the drum or pipe shell can be reused. Another type of drum with a replaceable shaft is the flanged type, where each side of the drum has a separate shaft connected to the main flange by a flange.

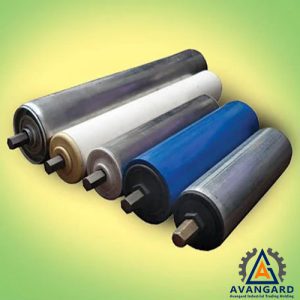

Types of Drums and Pulleys

Drums are designed and manufactured in different types, such as simple metal drums, rubber-coated drums, and rebar (network) drums. One of the most widely used types of rollers in conveyors is the rubber-coated and rubber drums. The rubber coating process on the drum surface is done through heat and sometimes adhesive, and these drums are made in three designs: simple, V-shaped, and diamond, each having its specific use. Roller shafts are usually one-piece, and in some cases, as per order, materials such as CK45 and a type of seamless pipe with a thickness of 8 to 20 mm are used. They are machined at an angle after assembly.

Properties of Fixed and Movable Conveyor Rollers

Fixed and movable conveyor rollers have unique features that ensure their performance in conveyor systems. Fixed rollers, due to their robust and stable structure, have a long lifespan and require less maintenance. Movable rollers provide more flexibility in conveyor adjustment, which is very useful in complex systems thanks to the ability to adjust the angle and position.

Application of Fixed and Movable Conveyor Rollers

Fixed and movable rollers are used in a wide range of industries. Fixed rollers are typically used in conveyor lines that do not require direction change, while movable rollers are used in systems where direction change and belt tension adjustment are necessary. These rollers are widely used in industries such as mining, cement, steel, and material transportation.

*For proper selection and use of various rollers, it is best to consult with Avangard experts and specialists. Also, noting the following can help extend the rollers’ lifespan and improve conveyor system performance:

- Appropriate Material: Choosing the roller material suitable for the type of material being transported and the environmental conditions

- Exact Dimensions: Selecting appropriate roller dimensions based on belt width and load capacity

- Alignment: Accurate installation and alignment of rollers

- Regular Lubrication: Timely lubrication of roller bearings to reduce friction and extend their lifespan

- Periodic Inspection: Performing regular inspections of conveyor components to identify and address potential issues

Purchasing Fixed and Movable Conveyor Rollers

For purchasing high-quality and reliable fixed and movable conveyor rollers, selecting the right supplier is crucial. Avangard, providing high-quality products that comply with international standards, is one of the best options for supplying these critical components. For consulting and purchasing, contact Avangard’s sales experts.

Selling Fixed and Movable Conveyor Rollers

As one of the leading suppliers of fixed and movable conveyor rollers in the market, Avangard offers its products with the highest quality and competitive prices. Selling these products with quality assurance and appropriate technical support provides peace of mind for customers.

Price of Fixed and Movable Conveyor Rollers

The price of fixed and movable conveyor rollers can vary depending on raw materials, dimensions, and technical features. Avangard strives to offer the best quality and the most suitable prices to its customers by providing competitive and appropriate pricing. For more information regarding prices and sales conditions, contact our experts.

| Row | Product Description | Price |

| 1 | Tension Roller Price | Contact for Price |

| 2 | Idler Roller Price | Contact for Price |

| 3 | Drive Roller Price | Contact for Price |

| 4 | Return Roller Price | Contact for Price |

| 5 | Support Roller Price | Contact for Price |

| 6 | Guide Roller Price | Contact for Price |

| 7 | Vibrating Roller Price | Contact for Price |

| 8 | Covered Roller Price | Contact for Price |

| 9 | Plain Metal Drum Price | Contact for Price |

| 10 | Rubber-Coated Drum Price | Contact for Price |

| 11 | Rebar (Network) Drum Price | Contact for Price |

| 12 | Head Pulley Price | Contact for Price |

| 13 | Tail Pulley Price | Contact for Price |

| 14 | Drum with Welded Shaft Price | Contact for Price |

| 15 | Drum with Replaceable Shaft Price | Contact for Price |

فارسی

فارسی Arabic

Arabic

Reviews

There are no reviews yet.