Shuttle Feeder Machine

Ready to send

Please contact the sales department for sending the list and bulk purchase of products.

Immediate shipment of the product is possible.

$0

Dear user, prices are being updated, please contact us.

Shuttle Feeder Machine

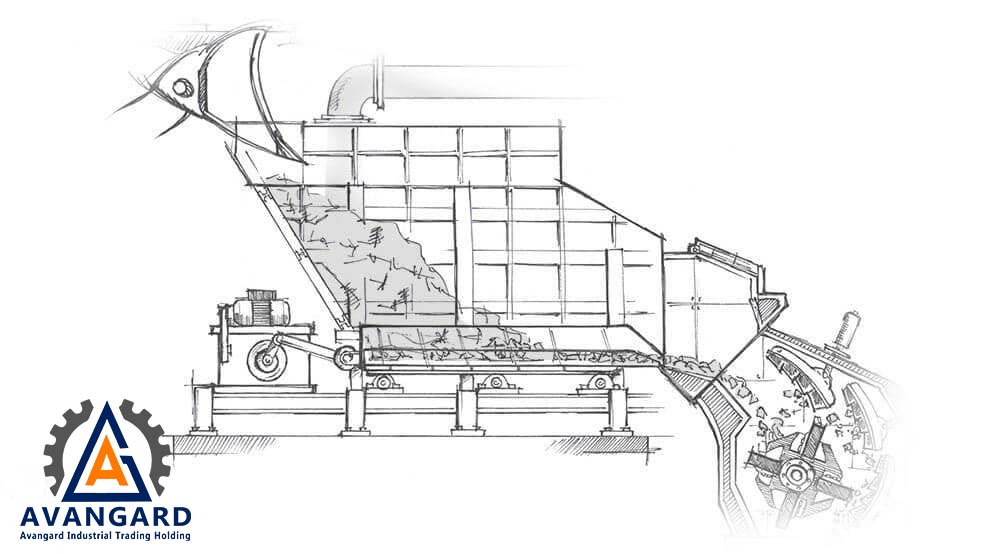

The shuttle feeder machine, also known as a reciprocating feeder, is suitable for coarse and moist materials. The mechanism of the shuttle feeder is based on the crank-shaft connection, and instead of using a vibrator to transport materials to the crusher’s entrance, it uses the reciprocating motion of the shaft. Therefore, shuttle feeders have the capability to efficiently feed moist and sticky materials (especially during rainy seasons) to subsequent equipment.

Shuttle Feeder Machine Features

- Reliable performance

- Easy to install and adjust

- High transfer efficiency

- Easy maintenance

- Ability to control input load to subsequent equipment

- Simple structure

- Significantly reduces feed leakage

- Long lifespan

The shuttle feeder machine has various applications, such that it can be installed at the beginning and in the middle of the production line (depending on the type of production at each location or separately), where with proper and precise adjustment, it provides excellent performance. In factories with high and medium production, this machine is placed in the middle of the production line, and in small factories, at the beginning of the line. The shuttle feeder machine is used in coal preparation plants, thermal power plants, coal washing, and bulk material handling ports, in industries such as mining, cement, food, sponge iron, and glass.

The shuttle feeder or mountain feeder has highly variable capacities and is manufactured according to the ordering factory’s capacity. It is worth noting that the output of this type of feeder can be changed from zero to maximum capacity at three exit points, movement stroke, and gearbox speed.

The shuttle feeder machine is used as a feeder for other machinery and equipment in the industry. It is used as a feeder for mineral processing lines that have stone materials and moisture. The shuttle feeder machine has a tray that involves reciprocating motion, which can be adjusted. This feature allows for proper loading of large and moist stone materials into subsequent machines, such as crushers.

The shuttle feeder, also known as the shuttle transfer plate in various industries, has highly variable capacity and is designed and manufactured based on the consumer’s needs and desired production capacity. An important and noteworthy point is that the materials exiting from this device can be adjusted from the minimum capacity to the maximum capacity in three separate sections.

| Technical Specifications of Shuttle Feeder | ||||

| Row | Feeder Type | Dimensions | Number of Decks | Motor Power (kw) |

| 1 | Shuttle | 5100*1000 | 1 | 18.5 |

| 2 | Shuttle | 6000*1200 | 1 | 18.5 |

A rod feeder with its smooth motion and ability to transport heavier materials is suitable for production lines that require slow and continuous feeding, but a vibratory feeder with its high accuracy, suitable operating speed, and adjustability is ideal for production lines that require uniform feeding, and a grizzly feeder is a good choice for feeding coarse materials and initial separation in heavy crushing lines, due to its simple design and high strength.

Shuttle Feeder Machine Price

The price of the shuttle feeder varies based on the type and capacity of the machine or any specific requirements of the customer and price fluctuations. To order, purchase, sell, or manufacture the desired feeder machine, contact our experts at Avangard Company.

We apologize, prices are being updated. Please contact Avangard Sales Department for price inquiries.

| Row | Description | Price in Toman |

| 1 | Shuttle Feeder Machine Price | Contact us |

فارسی

فارسی  Arabic

Arabic

Reviews

There are no reviews yet.